Air floation XY coordinates plane movoment platform

A coordinate plane and motion platform technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as frictional resistance that is difficult to increase acceleration, heat deformation of the motion platform, and affecting positioning accuracy, etc., to achieve structural rigidity, High positioning accuracy and reduced motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

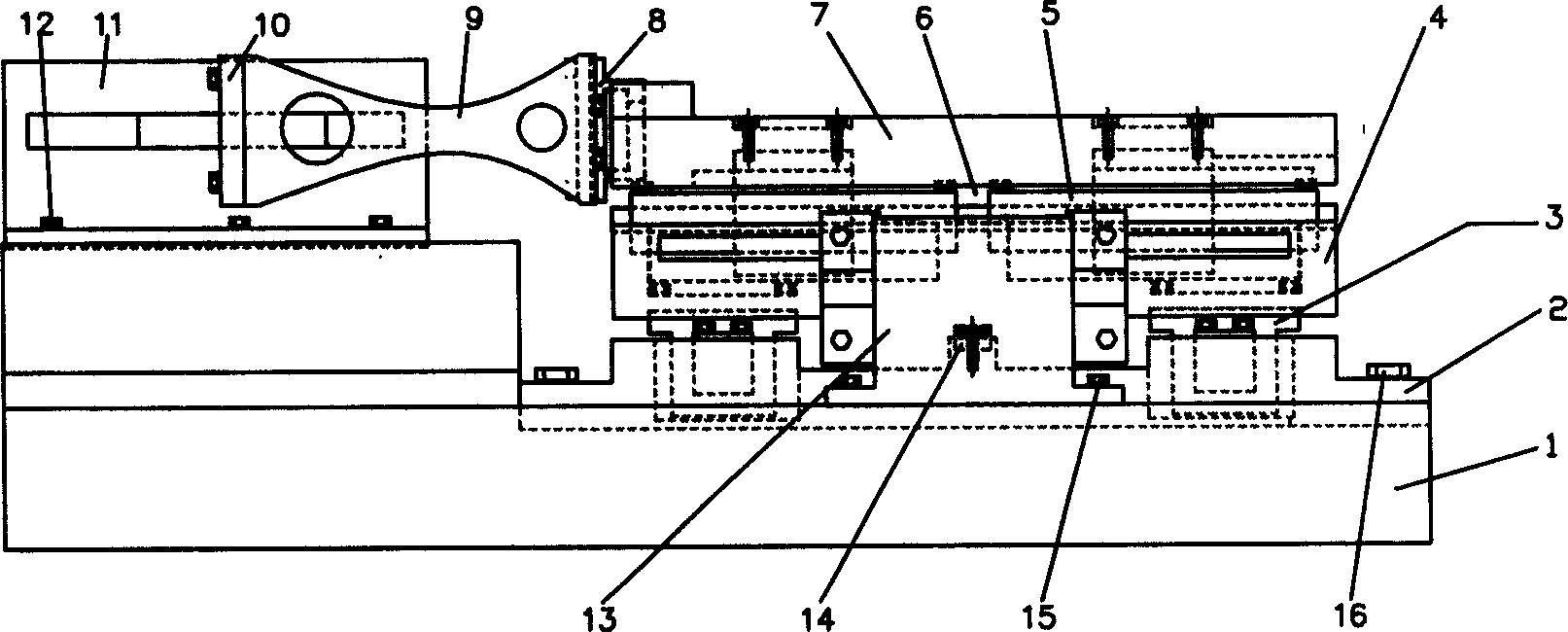

[0018] figure 1 It is the front view of the structural principle of the air-floating XY two-coordinate plane motion platform of the present invention.

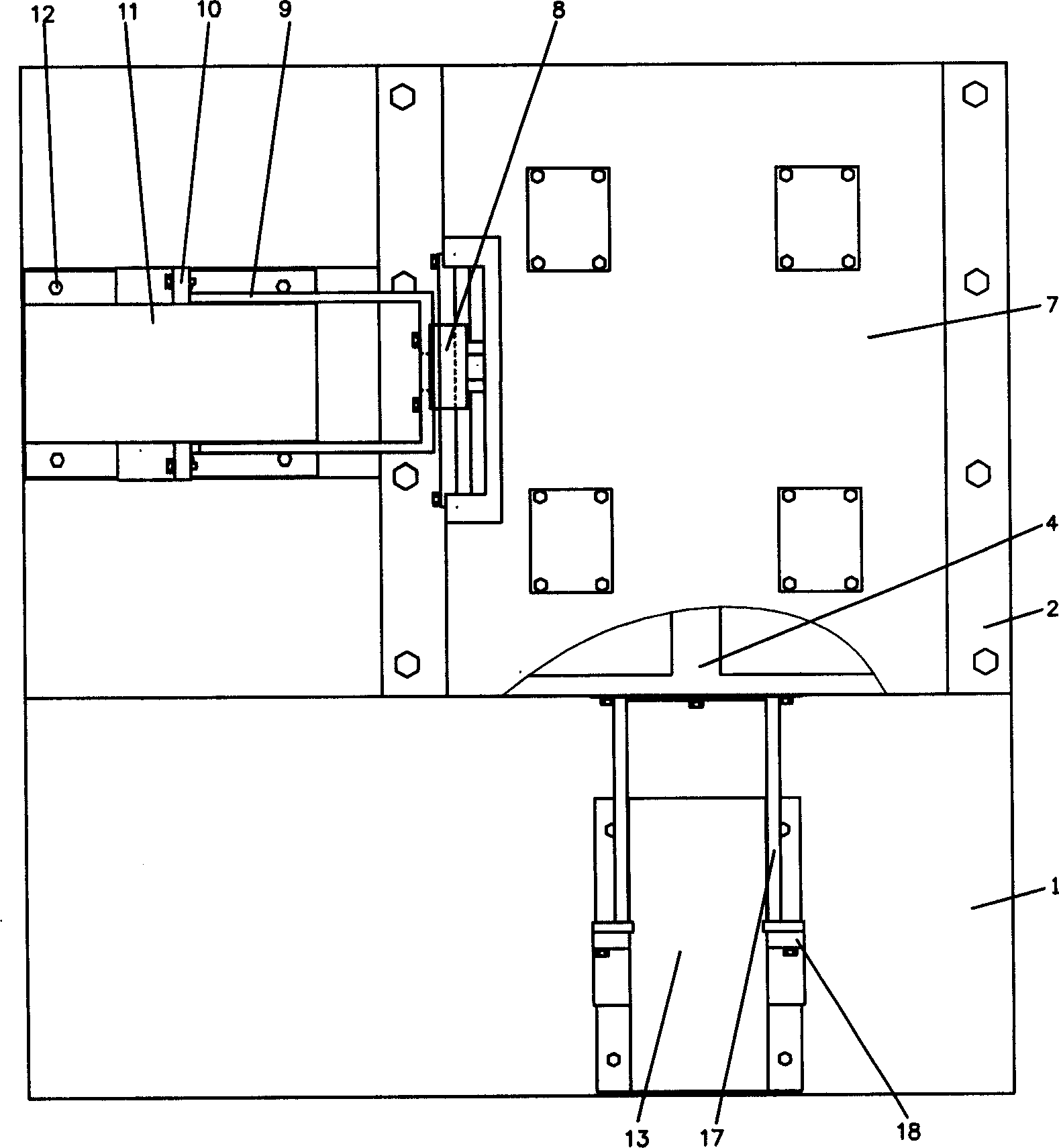

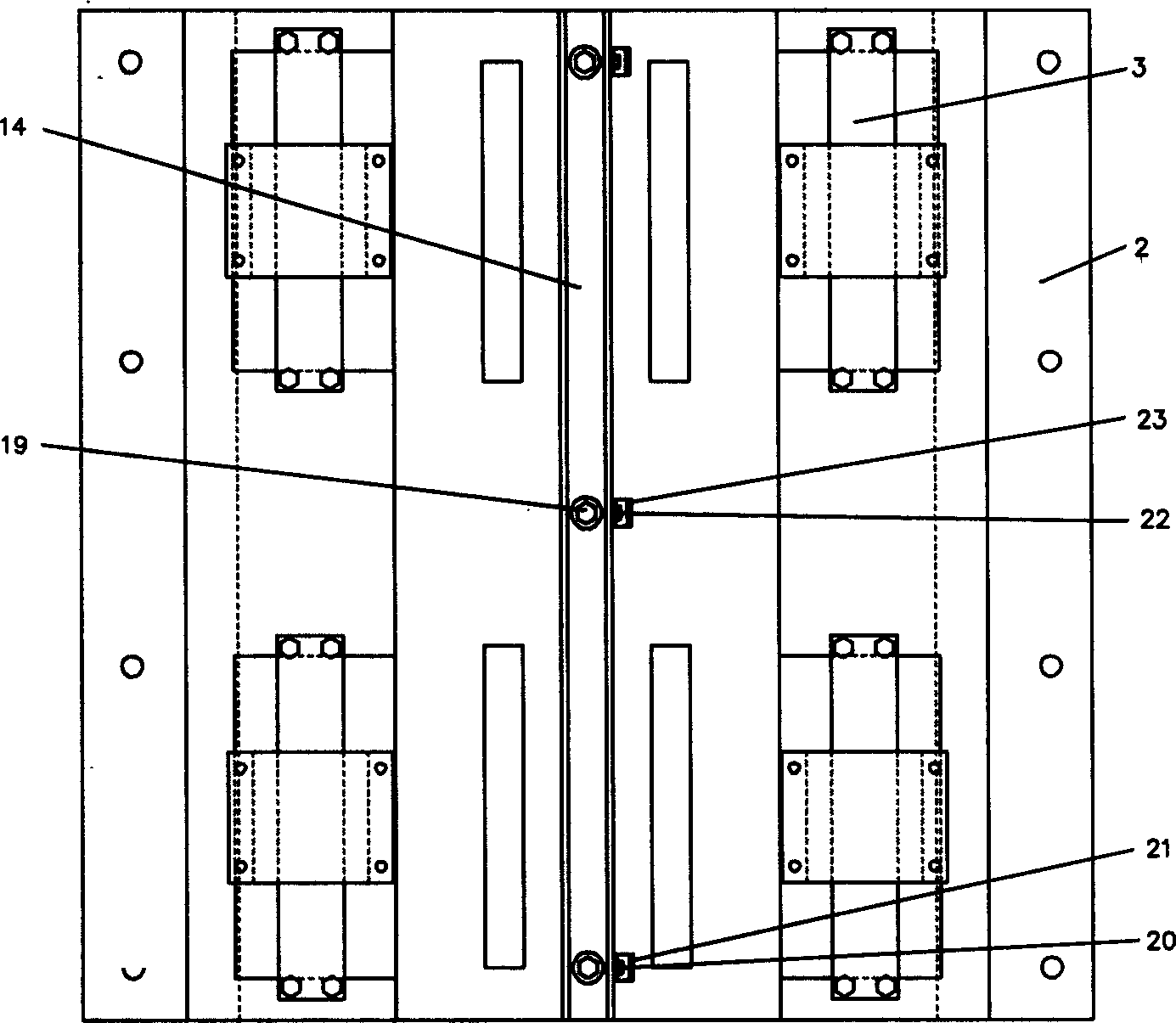

[0019] figure 1 Among them, the lower platform 2 is fixed to the base 1 by the lower platform fixing bolts 16 . The first group of air-floating guide rails 3 are respectively connected to the lower platform 2 and the middle platform 4 through bolts, and the second group of air-floating guide rails 5 are respectively connected to the middle platform 4 and the working platform 7 through bolts. The Y-direction linear motor mover 10 is connected to the Y-direction drive link 9 through bolts, the Y-direction linear motor stator 11 is fixed to the base 1 through the Y-direction linear motor fixing bolts 12, and the X-direction linear motor stator 13 is connected to the X-direction linear motor. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com