Short journey high responding linear motor

A linear motor, short-stroke technology, applied in the direction of electromechanical devices, electrical components, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

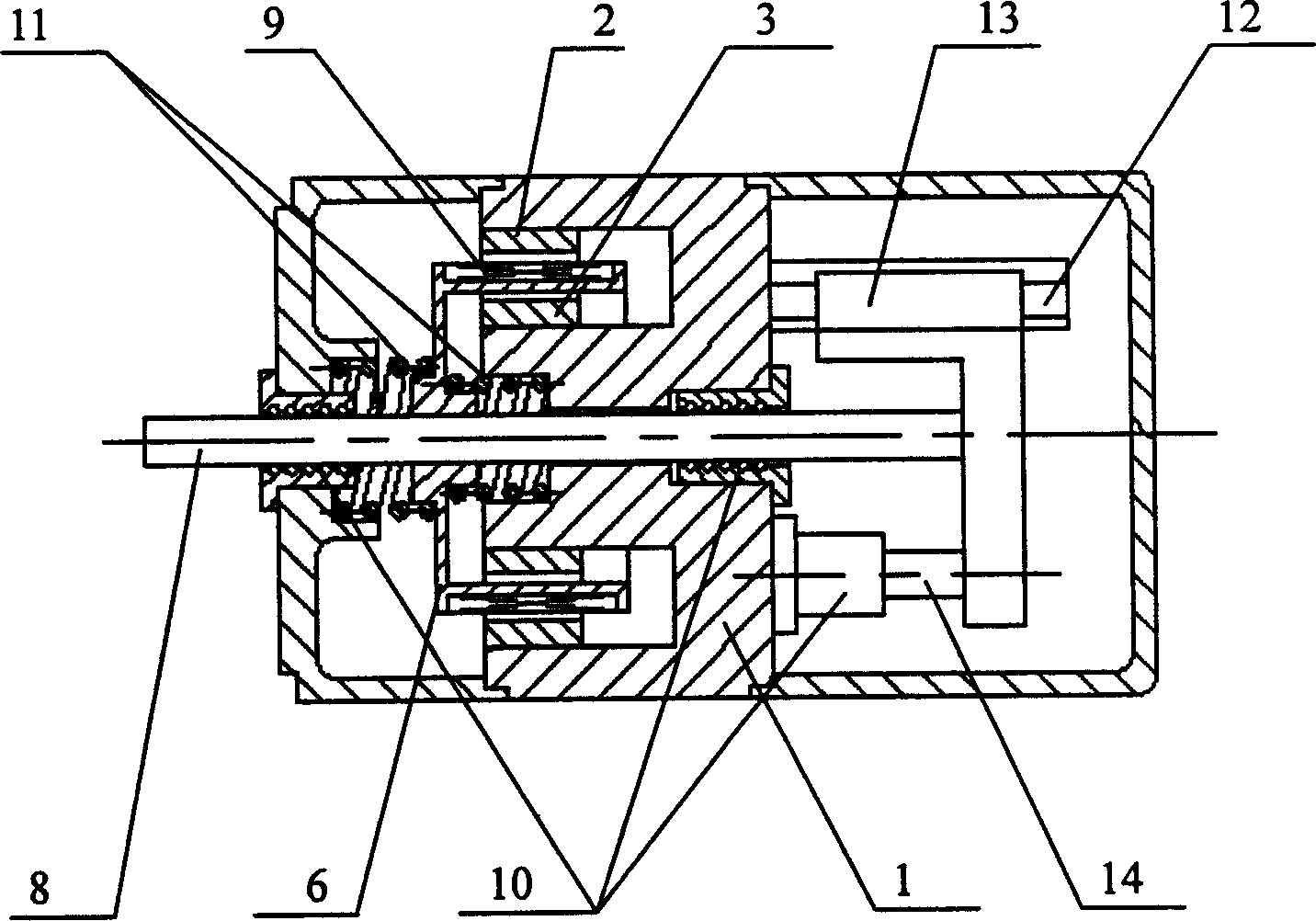

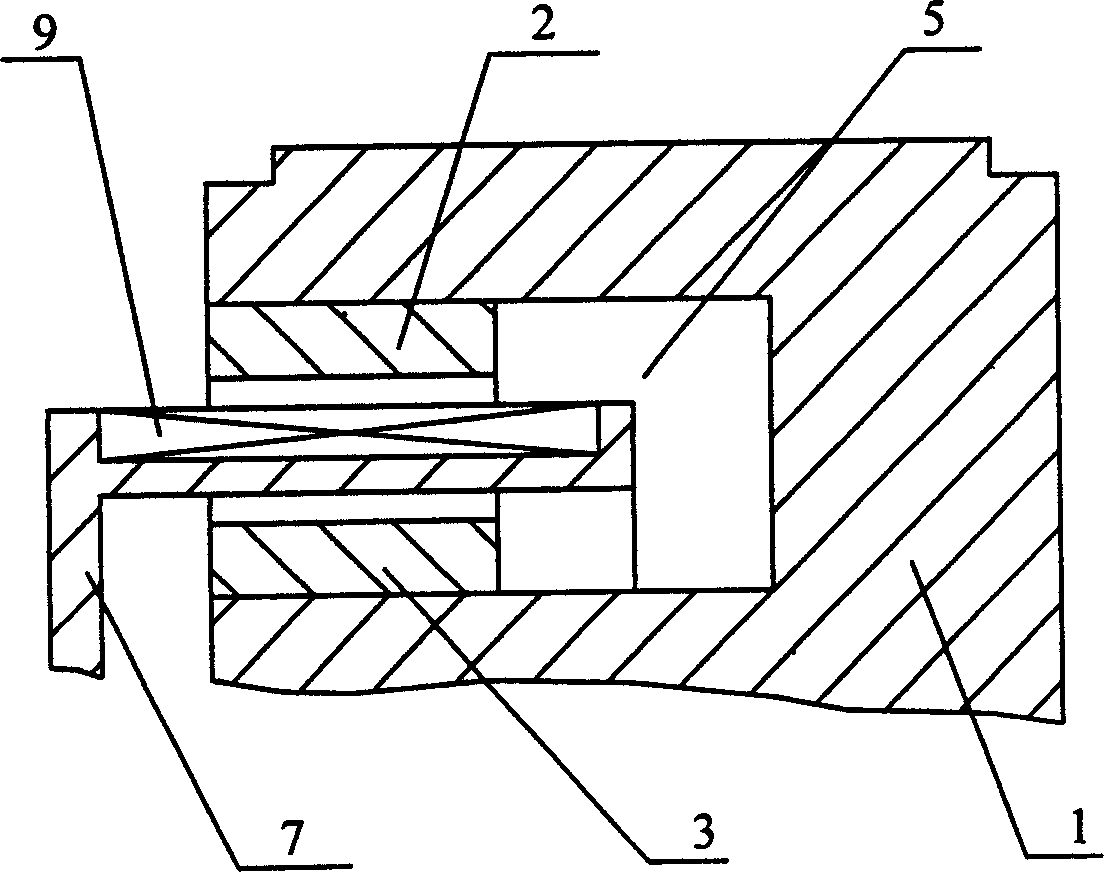

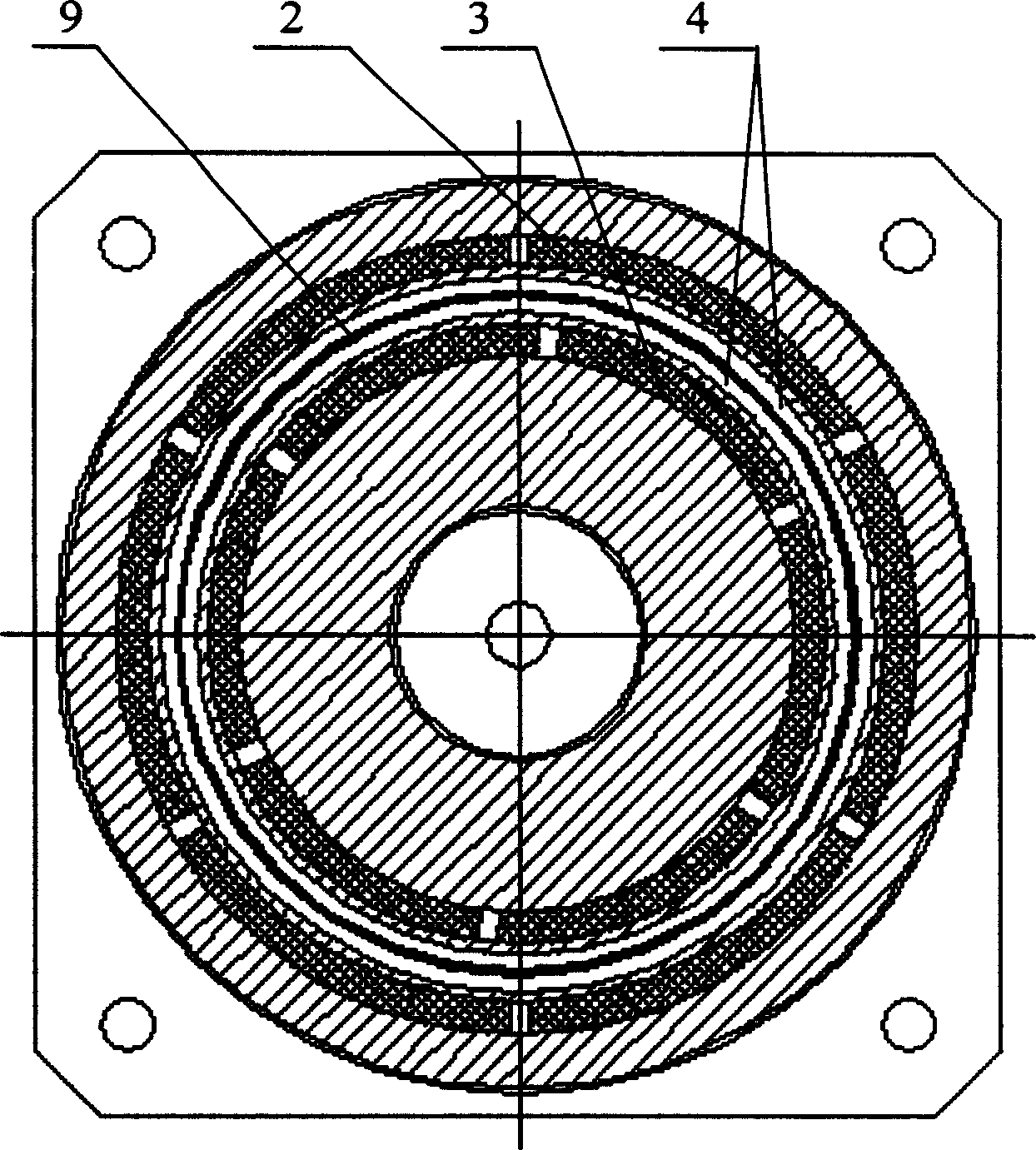

[0023] The implementation status of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] figure 1 Represent the overall structure of the present invention, as an embodiment: the effective stroke of the short-stroke high-response linear DC motor is ±5mm; figure 2 and image 3 It can be seen that there is an embedded annular groove 5 on the surface of the stator 1, and the outer annular magnet 2 and the inner annular magnet 3 embedded in it are all made of high-performance permanent magnet material NdFeB; the mover coil 9 is embedded in the outer annular magnet An air gap 4 will be formed between the steel 2 and the inner annular magnetic steel 3, and on both sides; the skeleton 7 of the mover 6 is made of duralumin alloy LY12; the mover coil 9 is 192 turns flat; The type of the linear bearing 10 is 5N / mm, the two ends of the shaft 8 and the eccentric position of the stator are LMF6GUU; the grating scale adopts the JENA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com