Light and steady high voltage transformer

A high-voltage transformer, a stable technology, applied in the field of transformer equipment, can solve the problems of impossible output, unable to obtain expected output, etc., and achieve the effects of avoiding chamfering, saving costs, and reducing equipment weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

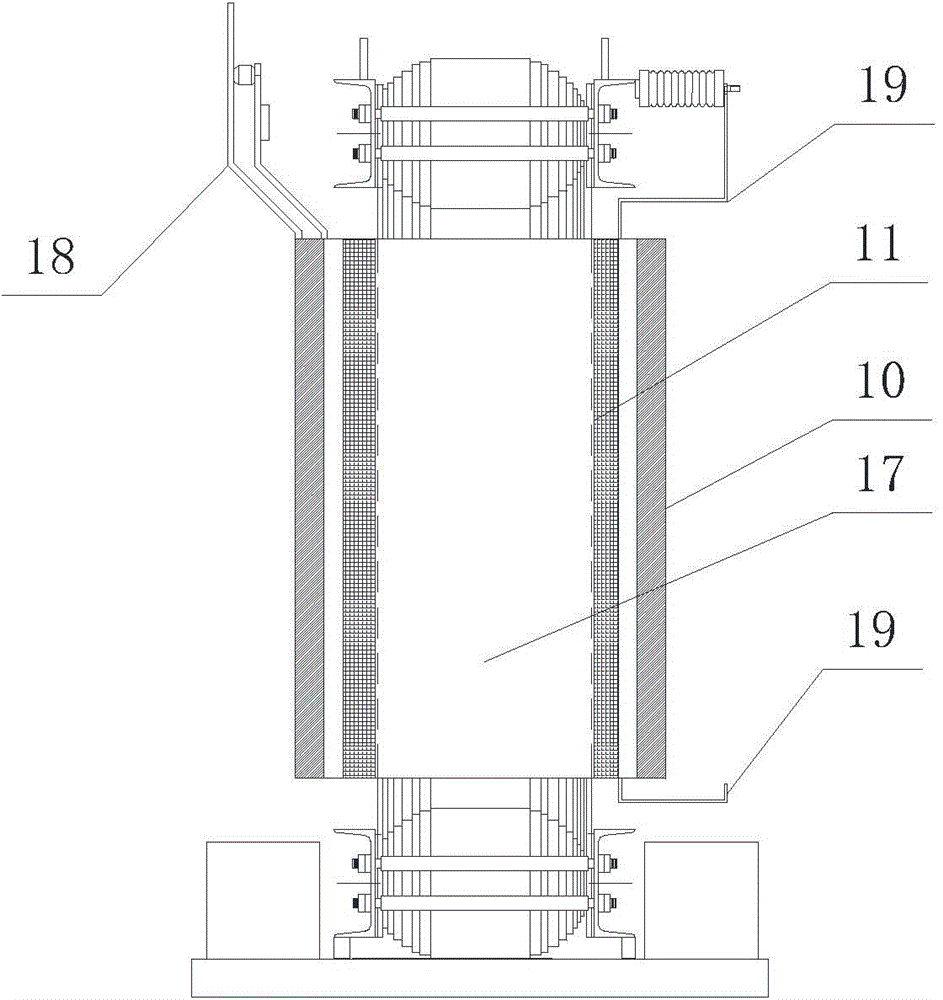

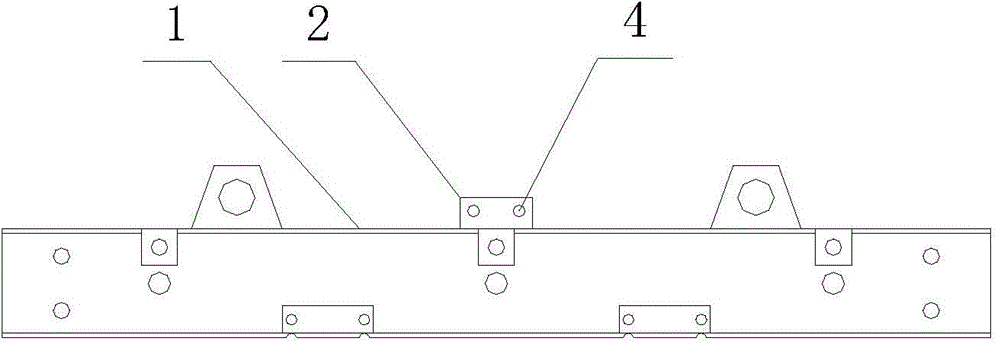

[0028] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , a light and stable high-voltage transformer, including an iron core 17, a low-voltage coil 10, a high-voltage coil 11, a clip 1, a channel steel 5, and a PVC pipe 6. The low-voltage coil 10 is provided with an outlet copper bar 4 positioning device, and also includes a pair of coils The clip 1 clamped and the connecting part between the two clips 1, the high-voltage coil 11 and the low-voltage coil 10 are respectively set on the iron core 17, the high-voltage coil 11 is inside, and the low-voltage coil 10 is outside; the slot The end of the steel 5 is welded and fixed with a bent plate 7 for installing the PVC pipe 6, and each bent plate 7 is provided with two small holes for binding the PVC pipe 6 with cable ties; the connecting parts include each clip 1. A tie-plate base 12 fixedly arranged in the middle, and a draw-plate 13 mated and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com