Rotary carbon electrode extruder and extruding method thereof

A carbon electrode and extruder technology, used in presses, material forming presses, manufacturing tools, etc., can solve the problems of uneven density of electrode products, poor product quality, and low pre-pressure The effect of high quality, high working pressure and high pre-pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

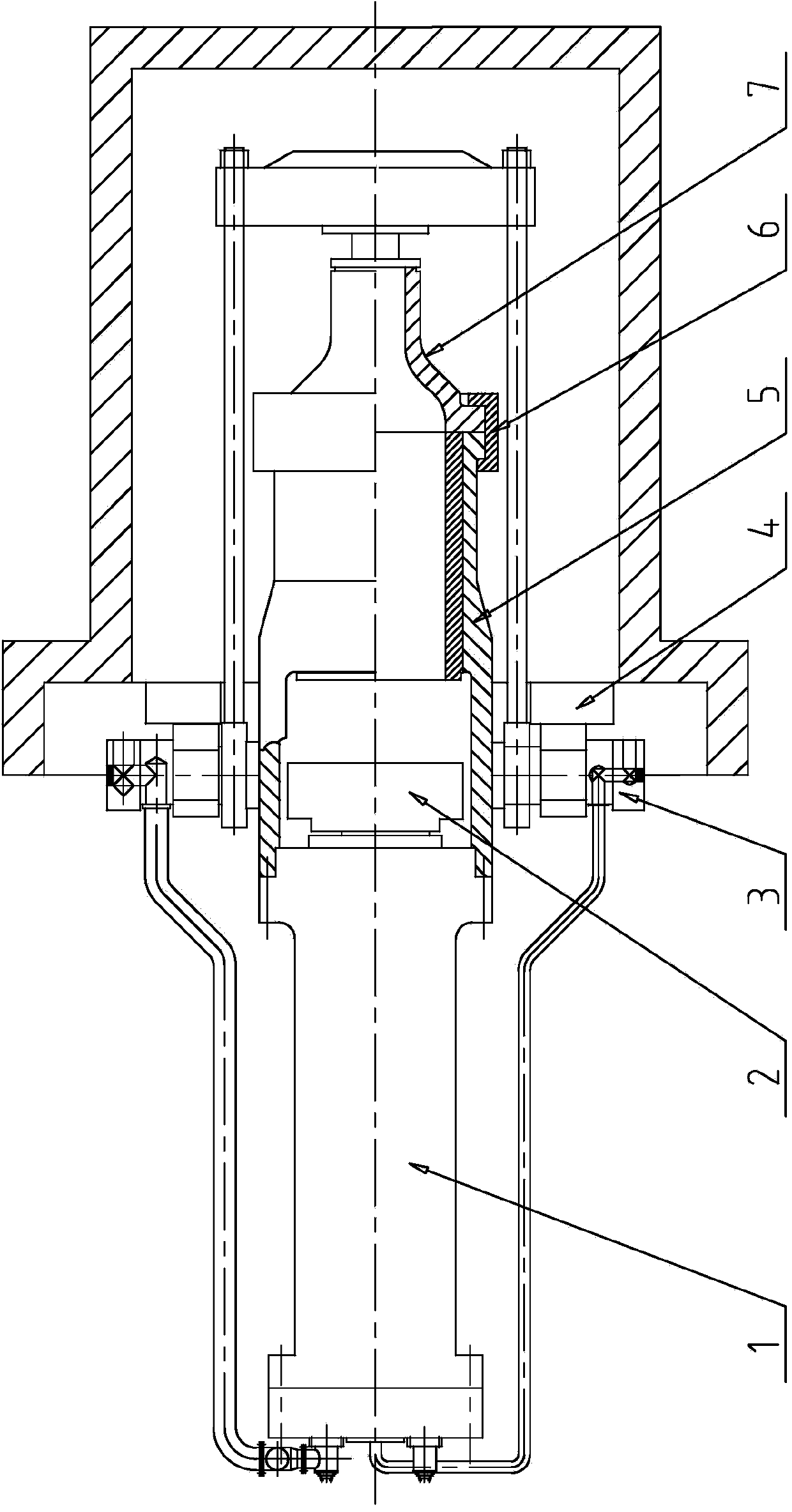

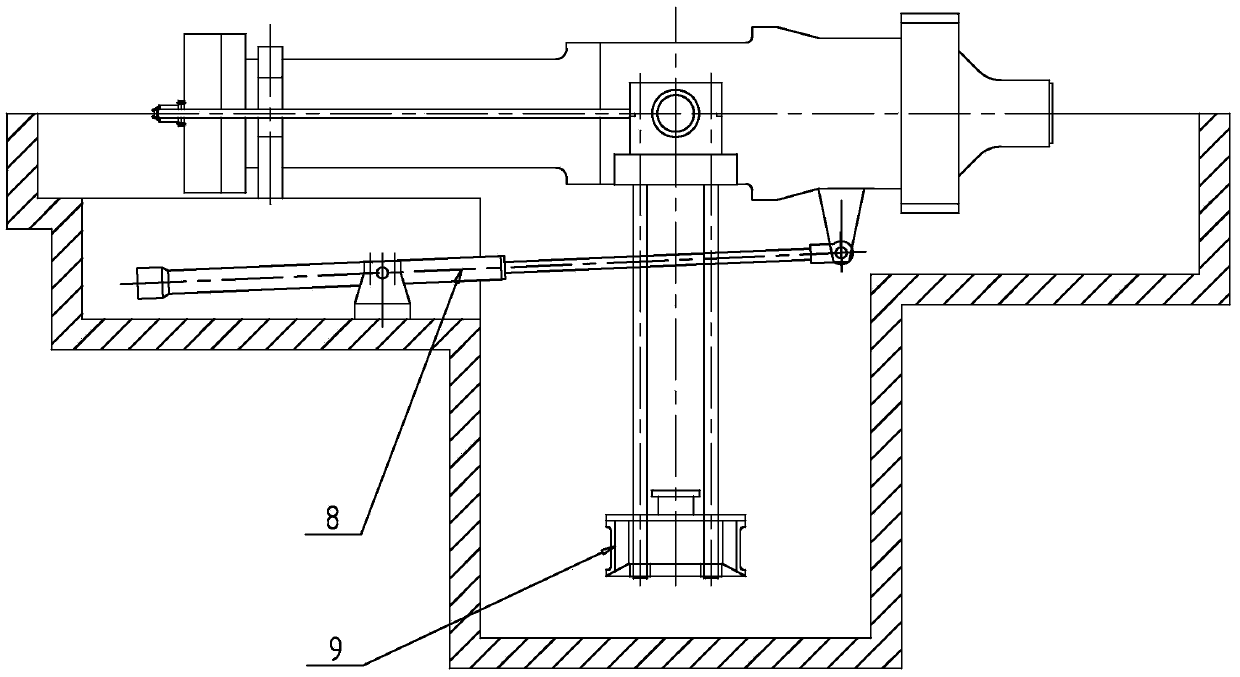

[0022] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, a rotary carbon electrode extrusion machine includes a main working cylinder 1, a support seat 4, a material chamber 5, a clamp 6, a nozzle 7, a rotating mechanism 8, a baffle mechanism 9, a rotary joint 3 and a vacuum system 2. The support seat 4 is fixed on the foundation, the material chamber 5 falls on the support seat 4 through the trunnion, the main working cylinder 1 is fixed on the upper side of the material chamber 5 by bolts, and the mouth shape 7 It is fixed on the lower side of the material chamber 5 by a clamp 6; two rotary joints 3 are respectively connected to the two trunnions of the material chamber 5, one rotary joint 3 is connected to high-pressure oil, and the other rotary joint 3 is connected to low-pressure oil; the vacuum system 2 is connected to At the end of the main working cylinder 1, the baffle mechanism 9 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com