Cantilever type floating steel strip bundling device

A cantilever and cantilever technology, which is applied to the parts of the strapping machine and other directions, can solve the problems of increasing the position of the strapping, the equipment is bulky, and cannot be provided, so as to improve the operating efficiency of the equipment, improve the packaging energy efficiency, and reduce the weight of the equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

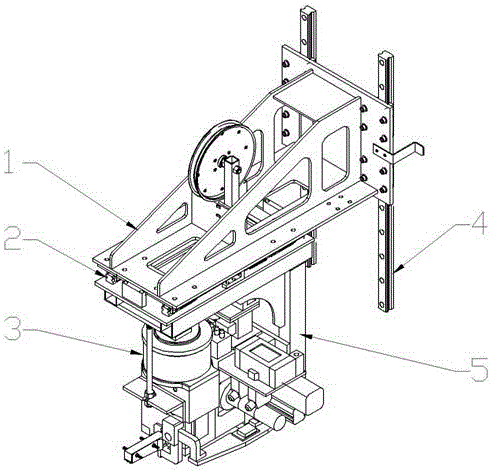

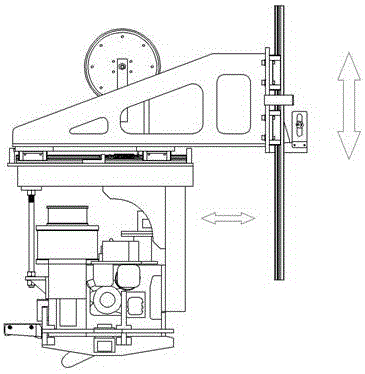

[0010] Combine below figure 1 and figure 2 , to further illustrate the present invention.

[0011] As shown in the figure, a cantilever type floating steel strapping machine device includes a cantilever frame 1, the bottom surface of the cantilever frame is fixed with a linear slide rail 1, and the side of the cantilever frame 1 is connected with a linear slide rail. Rail two 4; described linear slide rail two 4 is affixed to main frame, and described linear slide rail one 2 is connected small machine head frame 5; Described small machine head frame 5 is fixedly connected with bundling head 3, and described small One side of the head frame 5 is fixedly connected with a balance pull bar, and a reset extension spring is connected between the small head frame 5 and the cantilever frame 1 .

[0012] The cantilever frame is pushed by the transmission chain to realize the lifting movement. Because it is a single-sided cantilever rack, the overall equipment occupies a small space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com