Suction cup integrated robot

A robot and sucker-type technology, applied in the field of robots, can solve the problems of unfavorable flexible development of aircraft manufacturing and high cost, and achieve the effects of reducing the number of driving motors, reducing the weight of equipment, and opening up a working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

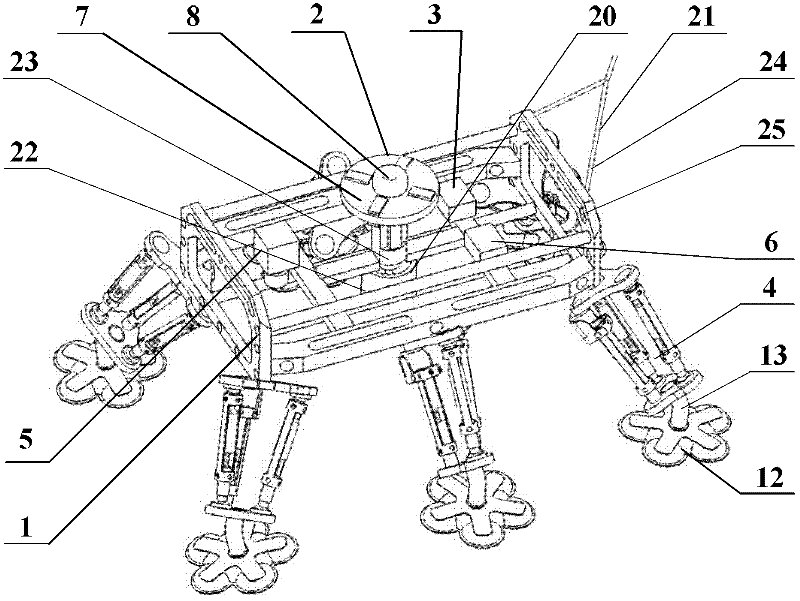

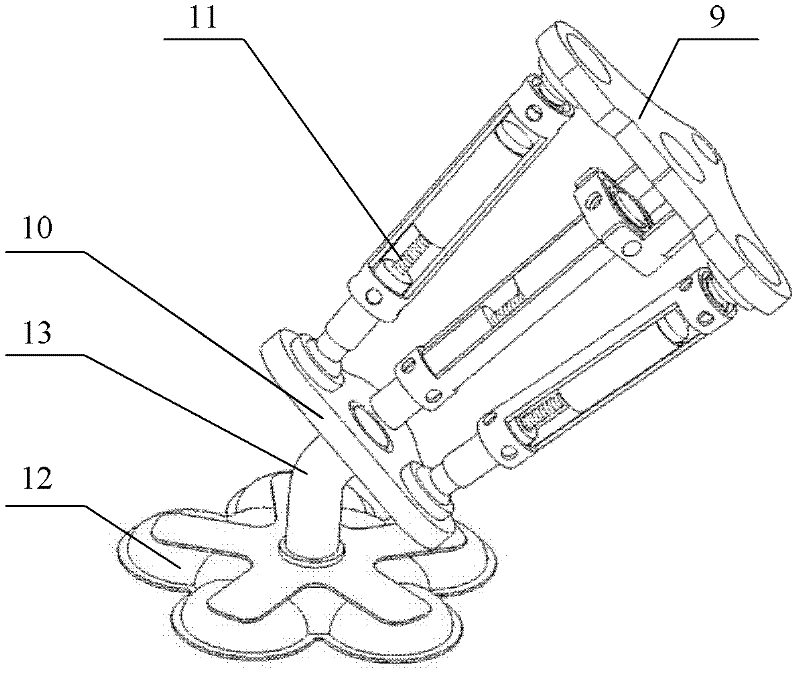

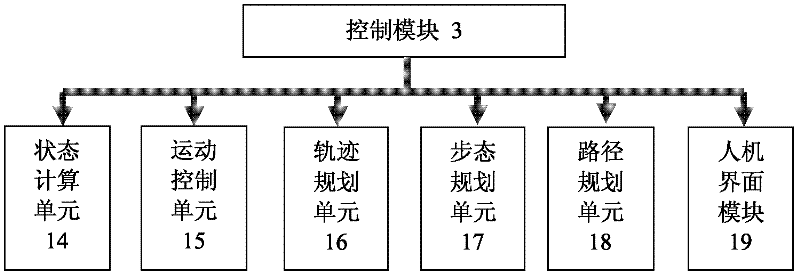

[0020] like figure 1 As shown, this embodiment includes: a frame 1, a hole making mechanism 2, a control module 3 and six sets of leg mechanisms 4, wherein: the six leg mechanisms 4 are respectively fixedly arranged around the frame 1 and the sensing mechanism 13 The output end of the hole making mechanism 2 is connected to the control module 3 to output the six-dimensional force sensor data, the hole making mechanism 2 and the control module 3 are fixedly arranged on the frame 1 and the control end of the hole making mechanism 2 is connected to the output end of the control module 3 and receives Control instruction.

[0021] The frame 1 is provided with a sensor group connected to the control module 3 , the sensor group is composed of a visual sensor 5 and a pose sensor 6 and outputs road condition information and three-dimensional pose data of the frame 1 to the control module 3 .

[0022] The hole-making mechanism 2 includes: a hole-making actuator 7 and a laser normal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com