Revolving-extrusion sealing device for pipe sealing machines

A technology of a sealing device and a sealing machine, applied in the field of rotary extrusion sealing devices, which can solve the problems of uneven thickness of the sealing wall, affecting the service life of metal pipes, and difficulty in forming a sealing wall, etc., to achieve good sealing effect, consistent thickness, and control convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

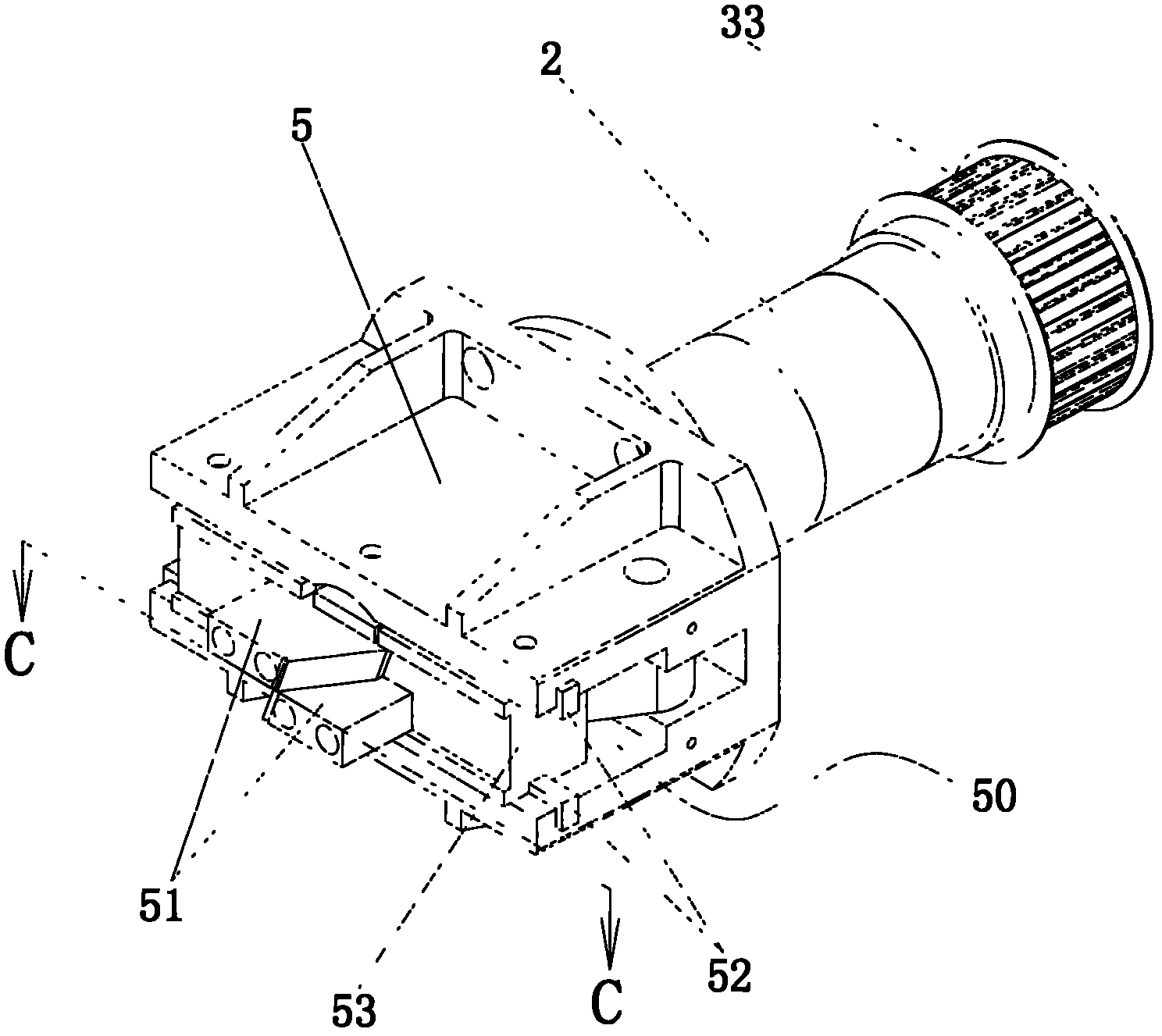

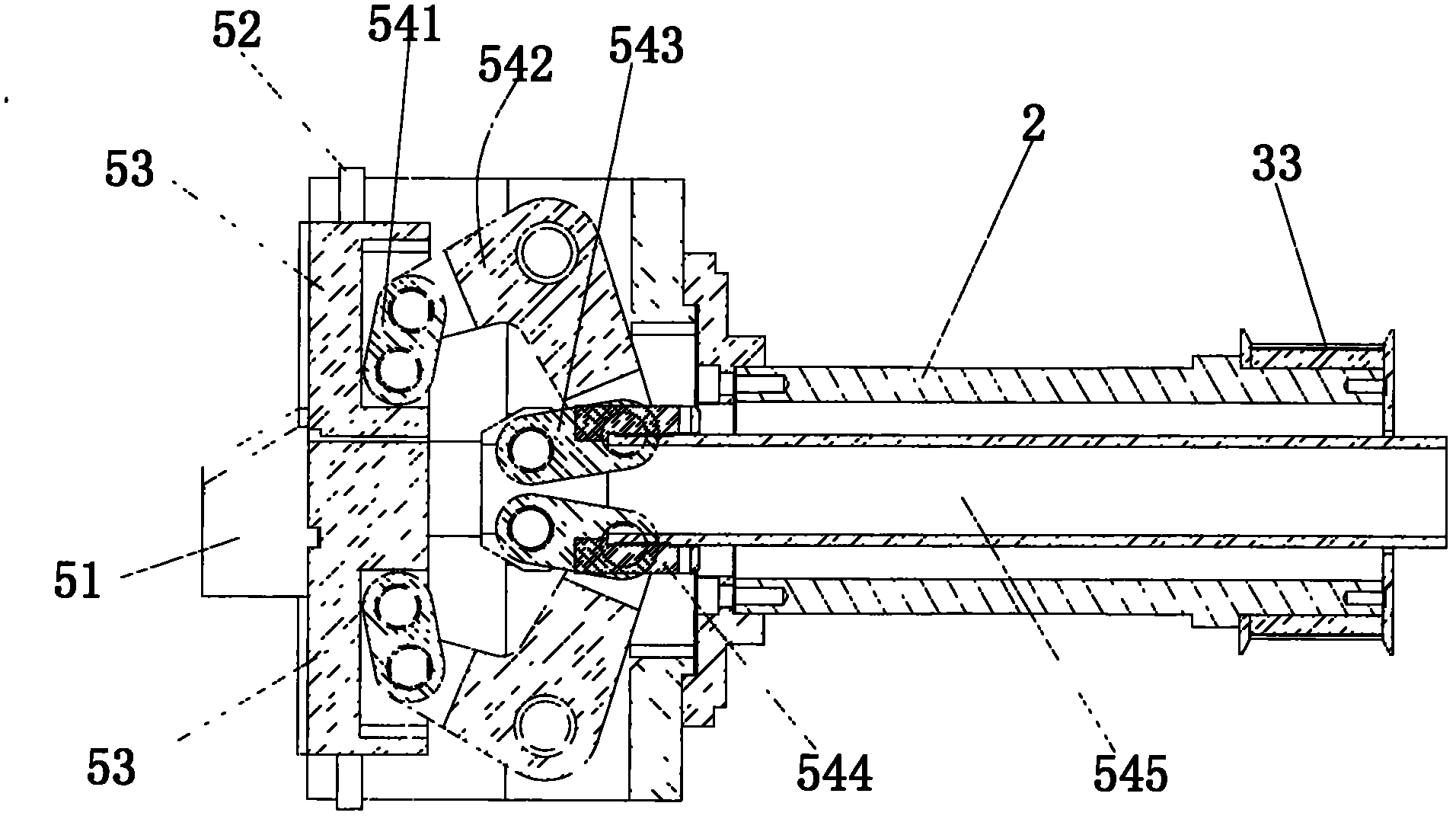

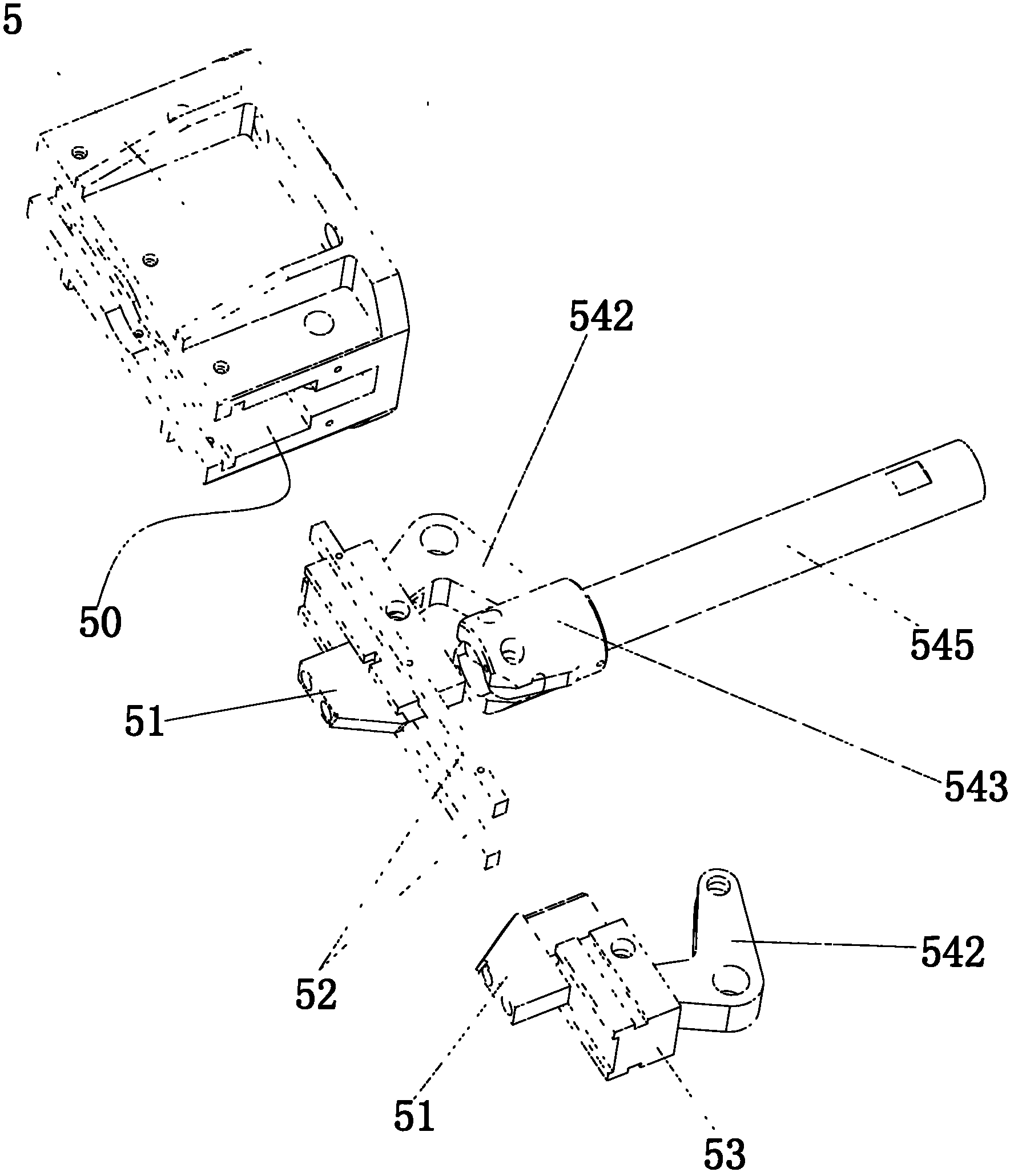

[0020] like Figure 1 to Figure 3 As shown, a rotary extrusion sealing device of a pipe fitting sealing machine includes a main shaft 2 pivotally arranged on the sealing machine frame 1 and positioned axially, a cutter head 5 arranged at the front end of the main shaft 2, and a sealing device arranged on the cutter head 5 The knife 51, the sealing knife guiding mechanism and the knife moving mechanism, the main shaft 2 is driven to rotate by the main shaft driving mechanism, and the sealing knife 51 slides in a direction perpendicular to the axis of the main shaft 2 under the guidance of the sealing knife guiding mechanism and approaches or moves away from the main shaft axis, The knife moving mechanism drives the sealing knife 51 to slide along the sealing knife guiding mechanism. The sealing knife guide mechanism includes a guide groove 50 on the cutter head 5, two upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com