Face gear numerical control machining device and machining method

A processing device, face gear technology, applied in gear tooth manufacturing devices, metal processing equipment, belts/chains/gears, etc., can solve the problem of lack of face gears, save processing time, facilitate operation, improve processing efficiency and process The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention takes the CNC gear shaping of the orthogonal face gear as an example.

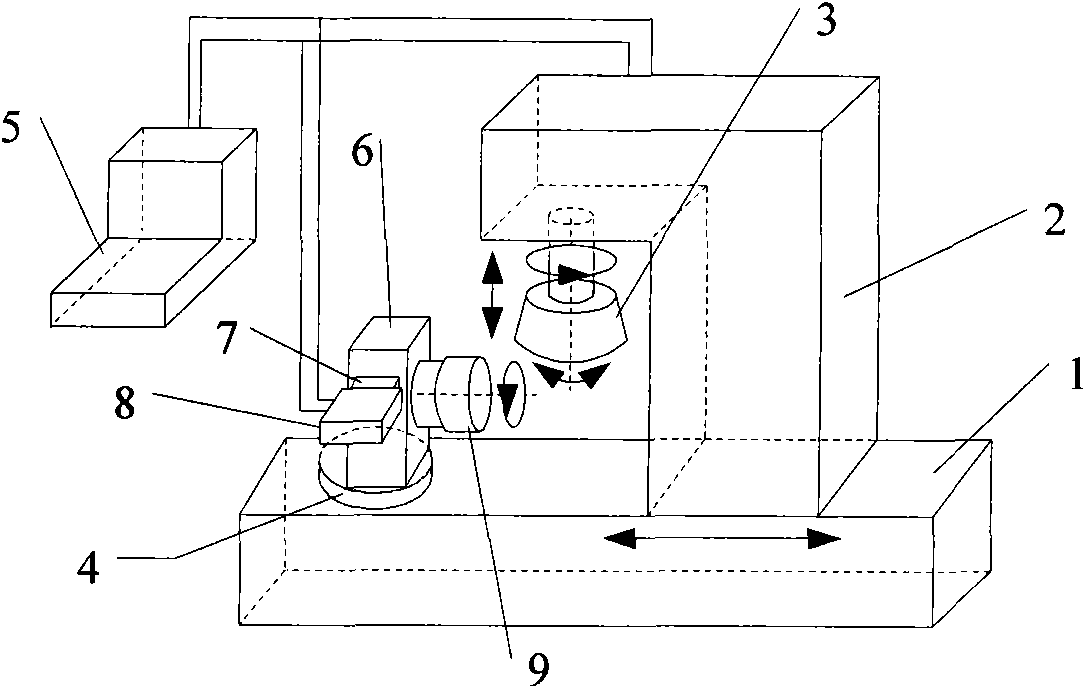

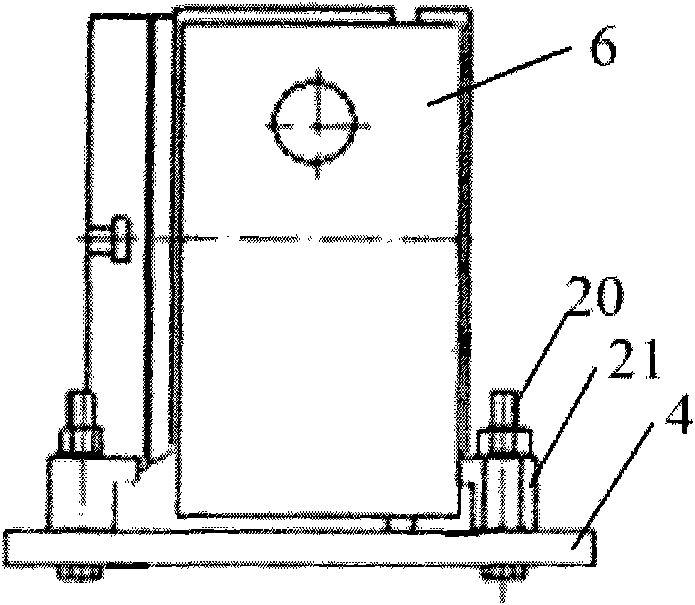

[0024] The overall idea of the present invention is as figure 1 Shown. The overall structure of the face gear processing device is: on the existing CNC work turntable 6, a transitional transmission device 7 (used to connect the CNC work turntable 6 and the motor 8 used in the CNC gear shaper rotary work turntable 4) is added to the motor 8 It is connected with the numerical control work turntable 6 and the numerical control system 5 is connected with the motor 8. The numerical control system 5 controls the operation of the motor and the various movements of the gear shaper to realize the movement required for the gear shaping. During the machining process, the main cutting motion of the machined face gear is realized by the up and down reciprocating movement of the face gear shaper cutter 3; the face gear shaper cutter 3 and the face gear workpiece 9 rotate around their own axes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com