Fully automatic sample-injection mechanism of flow cytometer

A flow cytometer, fully automatic technology, applied in the field of flow cytometer automatic sampling mechanism, can solve the problems of destroying test tubes and sampling needles, single swing direction, low sampling accuracy, etc., to save equipment costs, horizontal movement The effect of stabilization and improvement of sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

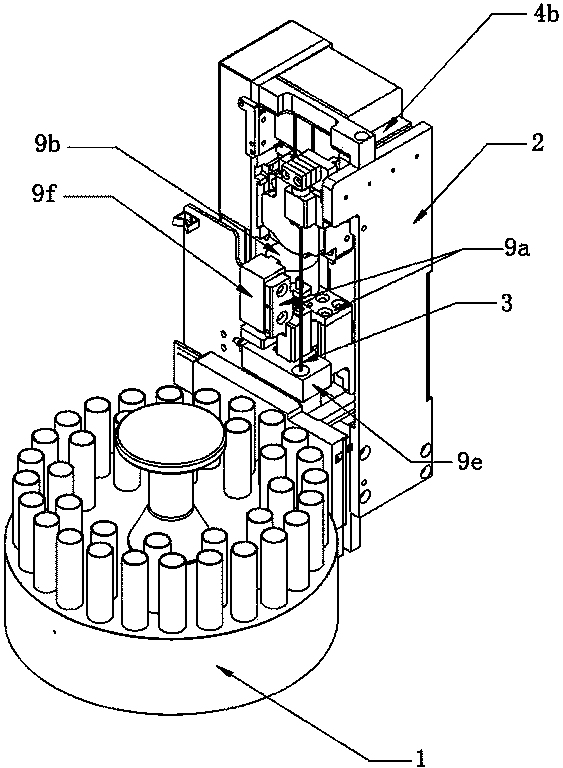

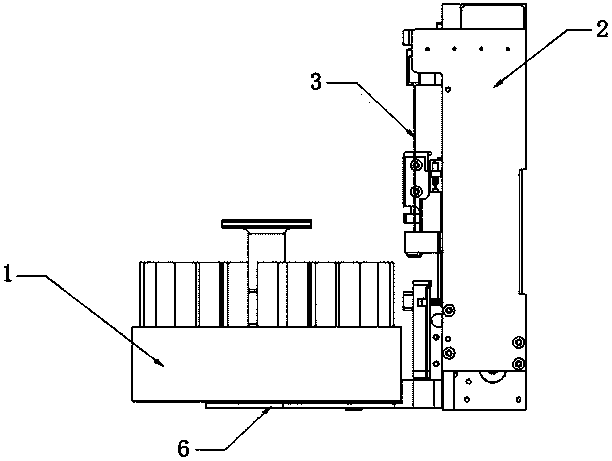

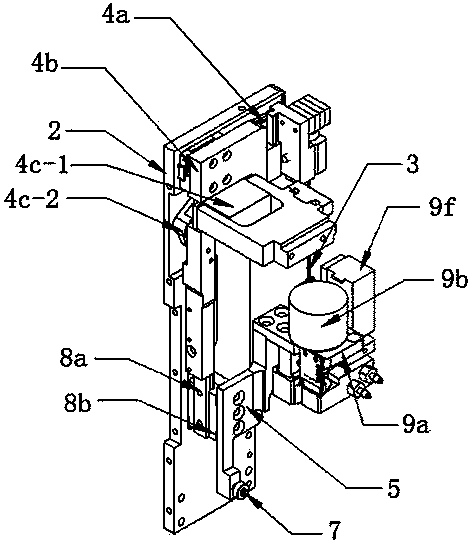

[0028] Example: refer to Figures 1 to 7 As shown, a fully automatic sample feeding mechanism for a flow cytometer includes a rotating disk 1 with a number of test tube installation holes distributed radially, an X-direction driving mechanism arranged on a fixed plate 2 on one side of the rotating disk 1, and a drive mechanism connected to the X-direction The sampling needle 3 connected to the drive mechanism and the Z-direction drive mechanism, the X-direction drive mechanism includes an X-direction slide rail 4a arranged on the fixed plate 2, a sampling needle drive plate 4b provided on the X-direction slide rail 4a, and a drive plate for driving Sampling needle drive plate 4b is a steering gear linkage driving mechanism that horizontally reciprocates along the X-direction slide rail 4a. The two-stage connecting rod 4c-2 connected with the plate 2 and the other end connected with the steering gear 4c-1; at the same time, the Z-direction driving mechanism is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com