Winding type circular template and production device of winding type circular template

A technology of production device and circular formwork, which is used in the joining of wooden veneer, adhesive application device, and other plywood/plywood appliances, etc. It can solve the problem of large size deviation of curved veneer mold, deformation of curved veneer, economic benefit discount, etc. problems, to achieve the effect of saving energy consumption and strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

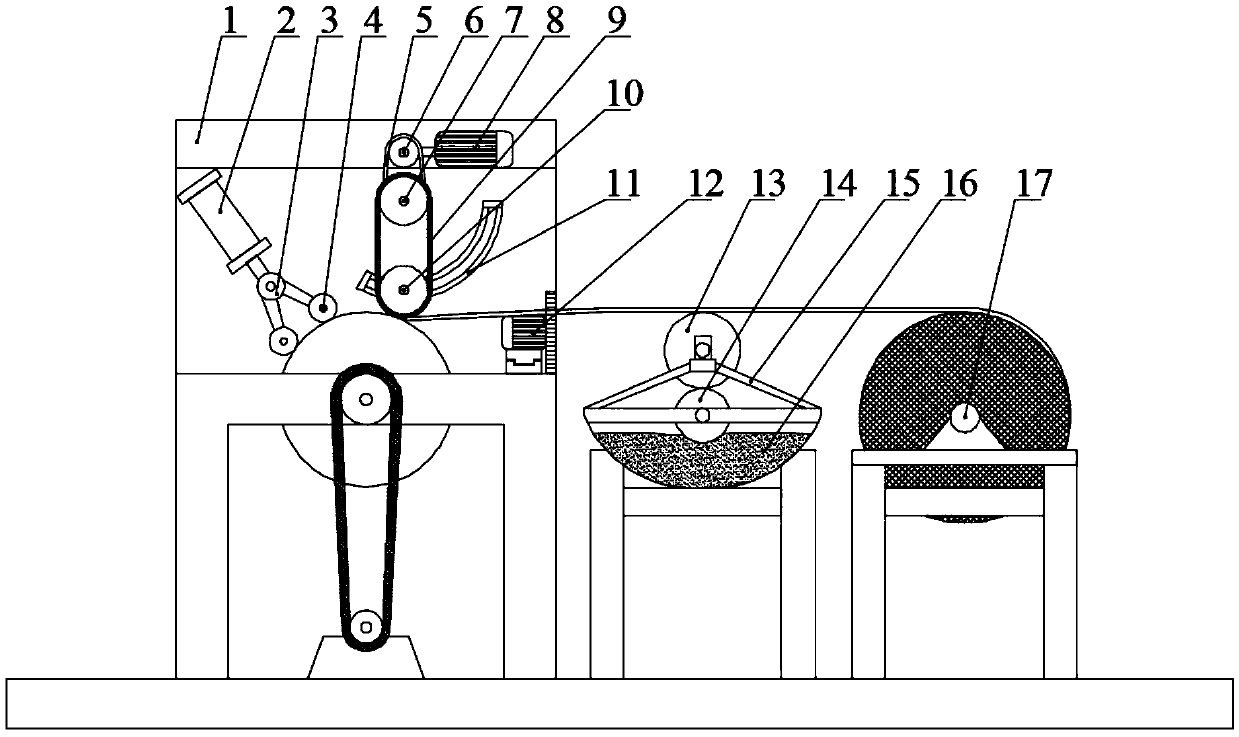

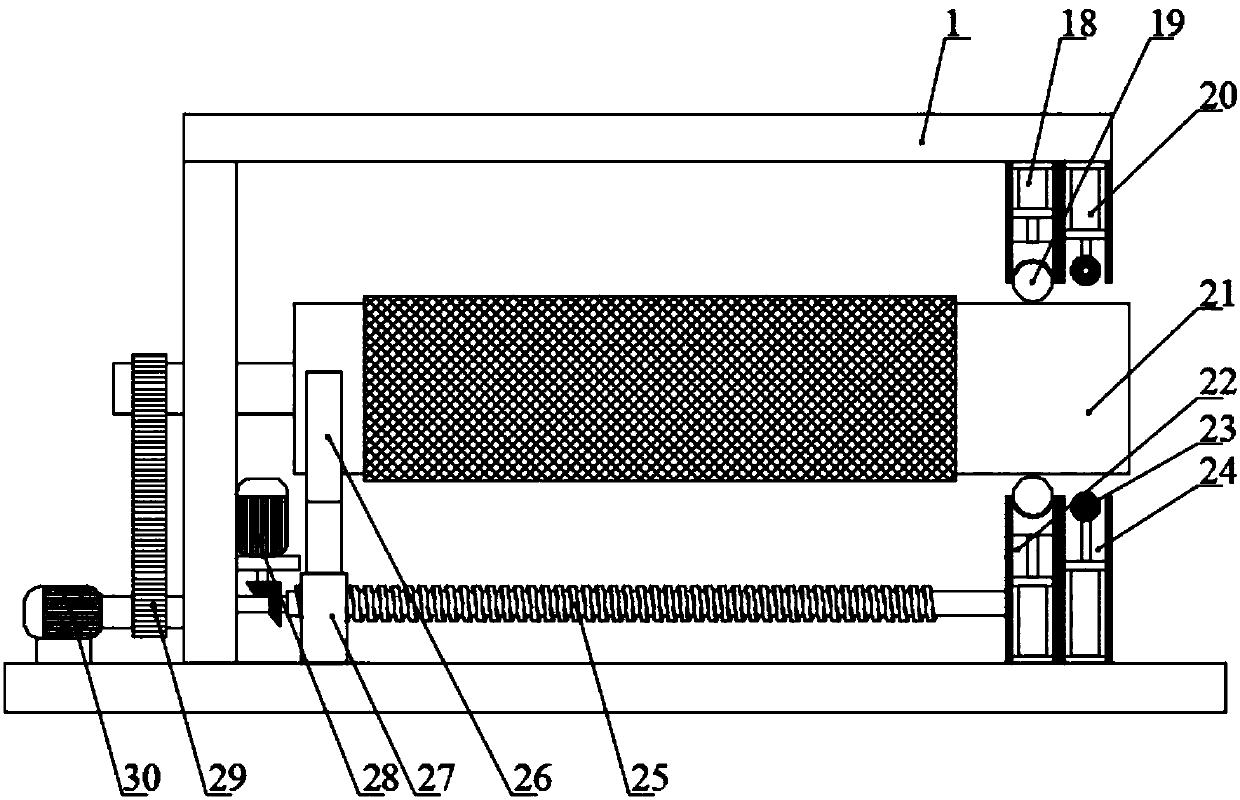

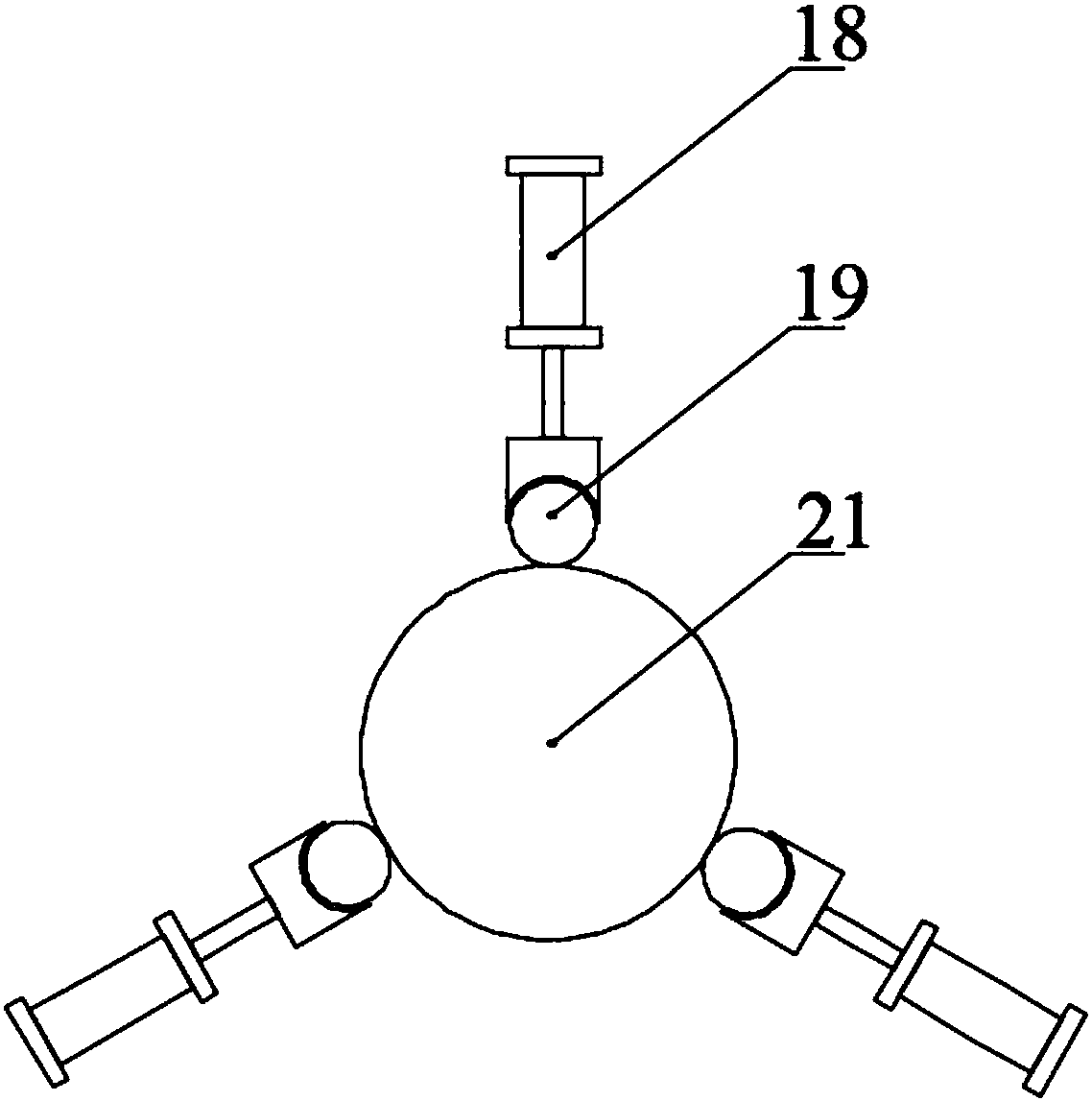

[0023] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0024] A winding circular formwork, the winding circular formwork is a cylindrical structure wound with multiple layers of veneer, wherein the multiple layers of veneer are compositely bonded, and each layer of veneer includes a horizontal grain veneer 31 and a vertical grain veneer 32; The veneer and the vertical veneer are compositely bonded, and the veneer seams 33 at the junction of the horizontal veneer and the longitudinal veneer are uniformly arranged along the circumference of the winding circular template.

[0025] Among the above schemes, the preferred technical scheme is: the production device of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com