Chute-mounted suspended steel rail vibration reduction fastener

A technology for vibration reduction fasteners and rails, which is applied in the field of rail vibration reduction and noise reduction, can solve problems such as inability to effectively control the movement of brackets, and achieve the effects of increasing restraint rigidity and stability, reducing dynamic deformation and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

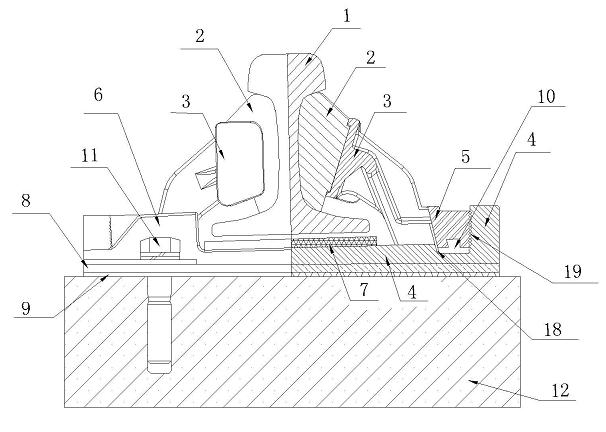

[0033] The present invention is described in conjunction with accompanying drawing and specific embodiment:

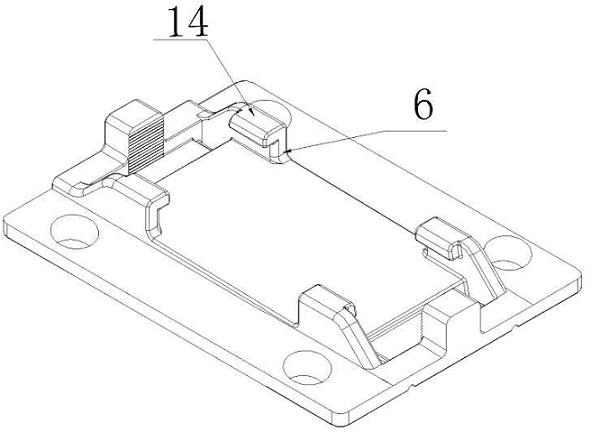

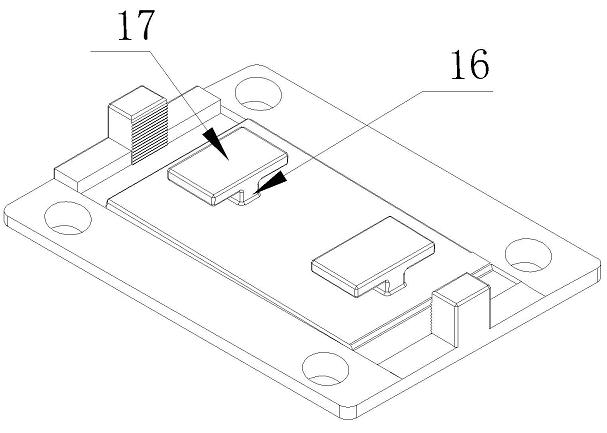

[0034] Such as figure 1 As shown, in the suspension rail damping fastener installed in the chute type, a group of non-metallic elastic bodies 2 are arranged symmetrically on both sides of the rail 1, and the material of the non-metallic elastic body can be rubber, or plastic, or rubber Plastic blend, its internal density can be uniform or uneven; the end face radian of the non-metallic elastomer 2 matches the radian of the rail waist, and the contact surface between the non-metallic elastomer and the rail can be smooth or have grooves structure, stud structure, groove structure, conical structure; several sockets or grooves are provided on the bottom surface of the non-metallic elastic body 2, so as to connect the non-metallic elastic body 2 with the lateral bracket 3; the non-metallic elastic body is fixed on the side The way on the bracket can be plug-in type, can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com