Oil and gas transmission pipeline laying and mounting construction method

A technology for conveying pipelines and construction methods, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problem of inability to ensure the uniformity of the gaps in the connection parts of the pipelines, the labor intensity of the manual control of the pipeline connection, and the impact on the pipeline. Welding effect and other issues to achieve the effect of ensuring stability, low work efficiency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

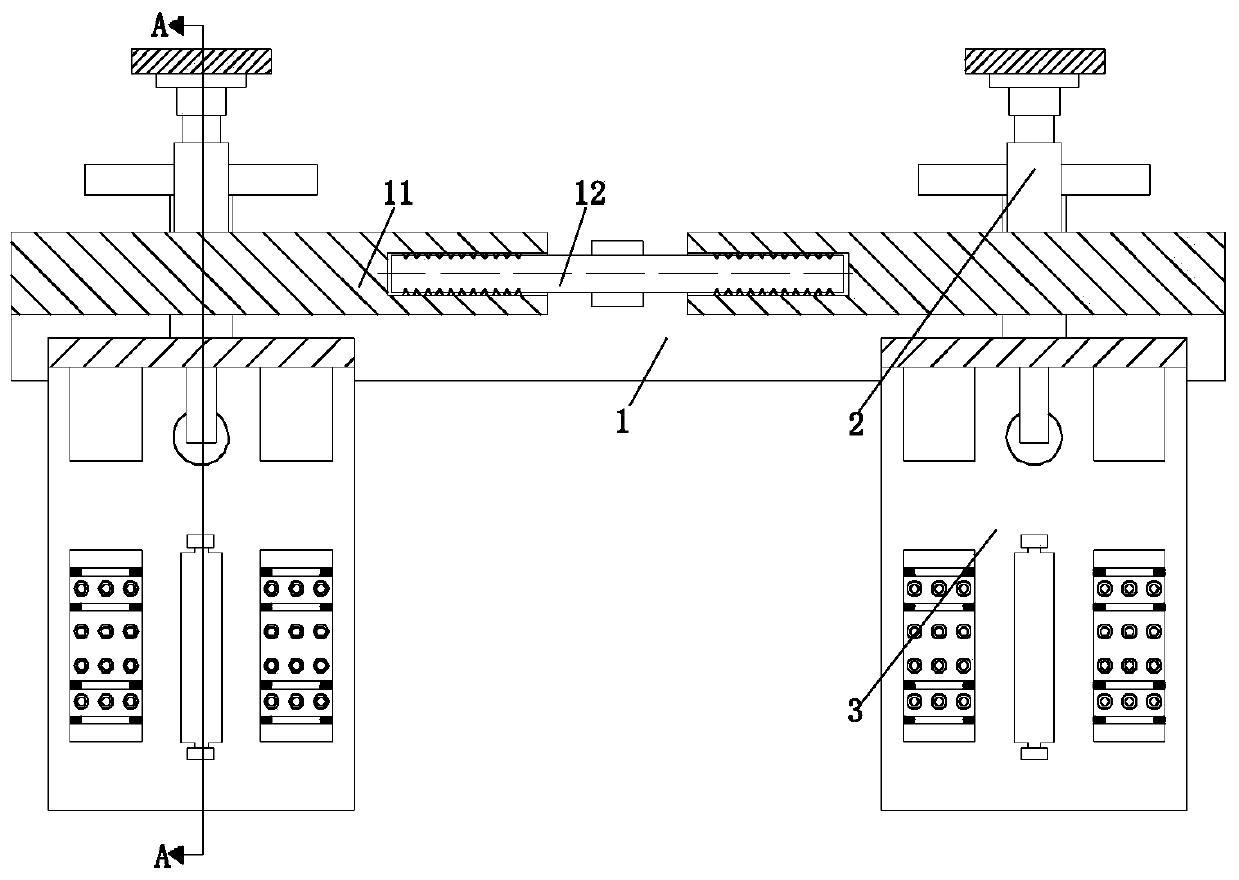

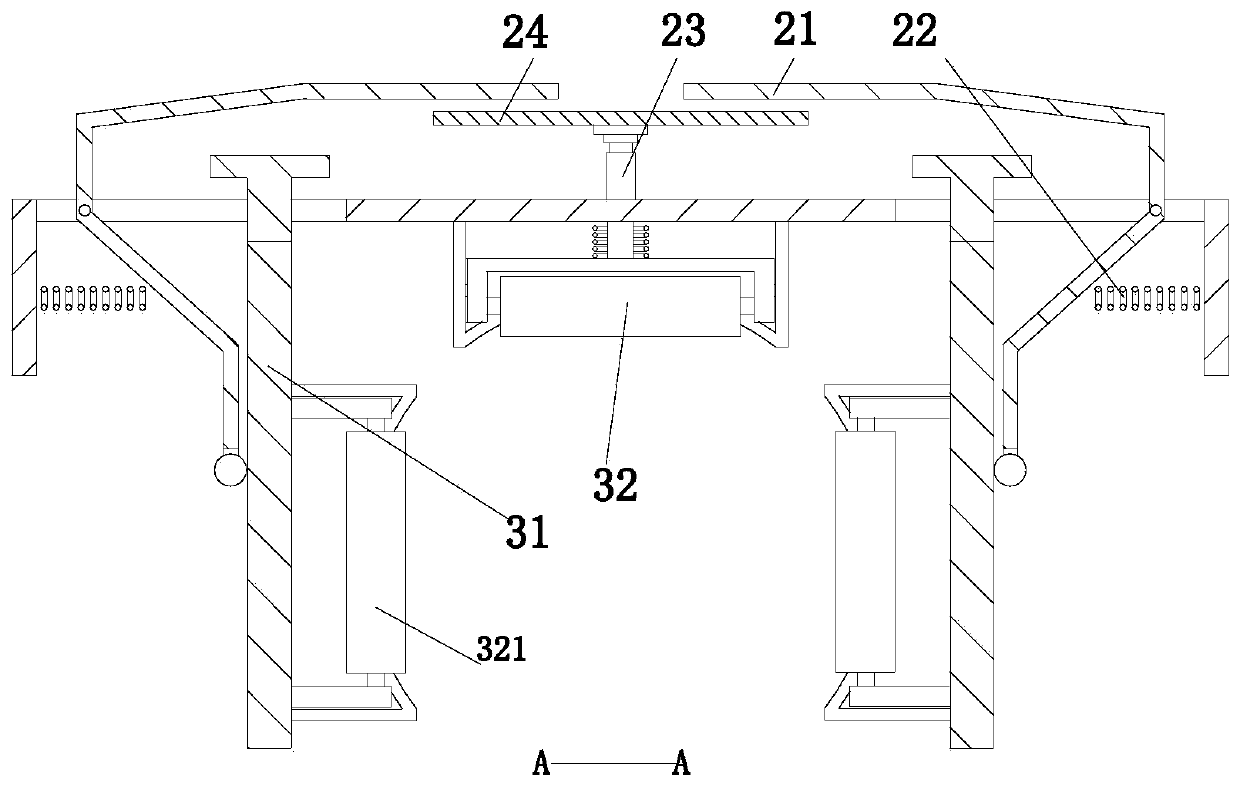

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

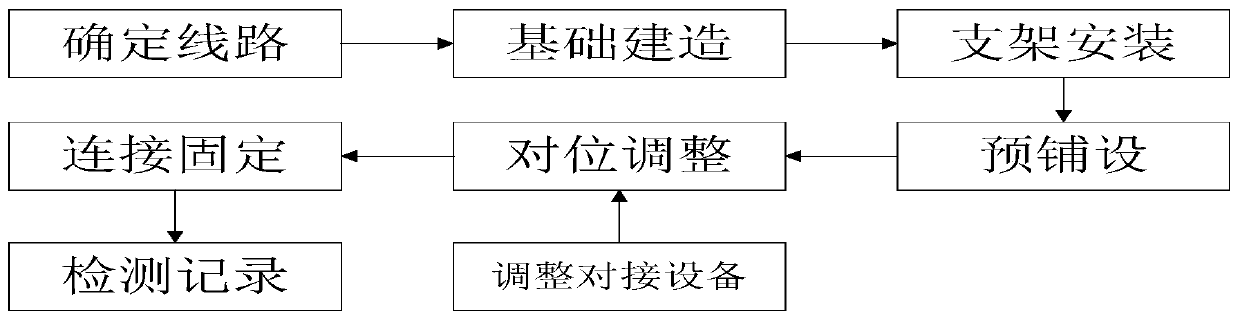

[0033] like Figure 1 to Figure 5 As shown, a method for laying and installing oil and gas transmission pipelines, step 1, determine the line, use a leather tape to measure the line of the pipeline laying line, use white lime to mark along the path measured by the leather tape, the thickness of the white lime is 5-7 mm;

[0034] Step 2. Foundation construction. Use an excavator to dig out the installation pit at the position marked in step 1, transport the soil in the installation pit, use a rammer to tamp the installation pit, and pour concrete into the installation pit at an interval of 3-5m. Cement platform, the thickness of the cement platform is 10-20cm;

[0035] Step 3. Bracket installation. Use a drilling machine to drill installation holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com