Printed circuit board assembly (PCBA) on-line cleaning machine

A cleaning machine and chemical cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of poor cleaning effect, difficult cleaning of flux residues, etc. Rinse for full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

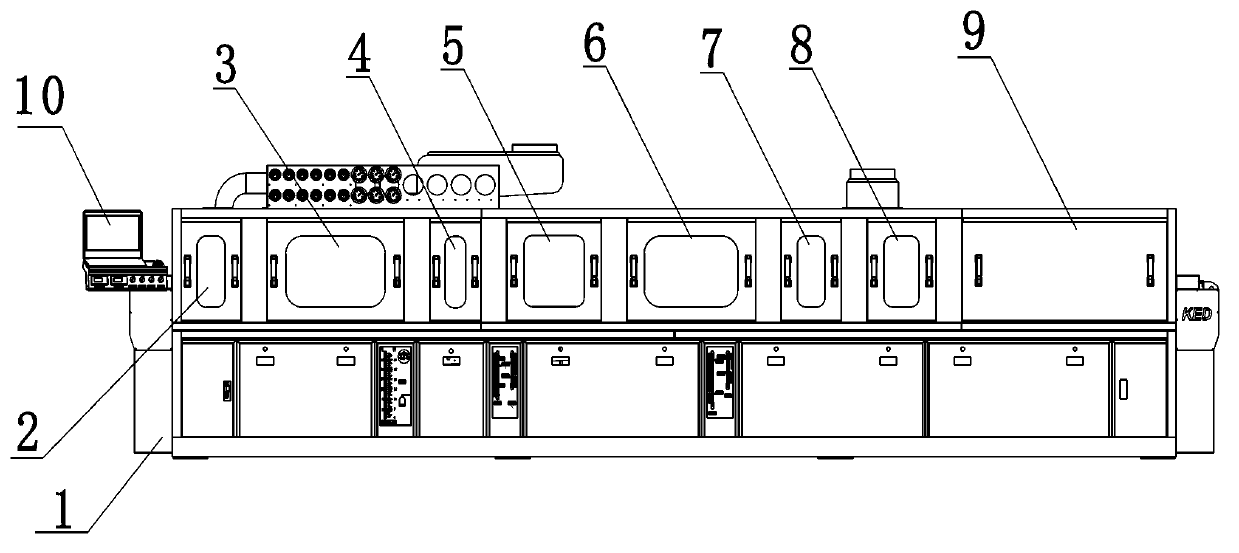

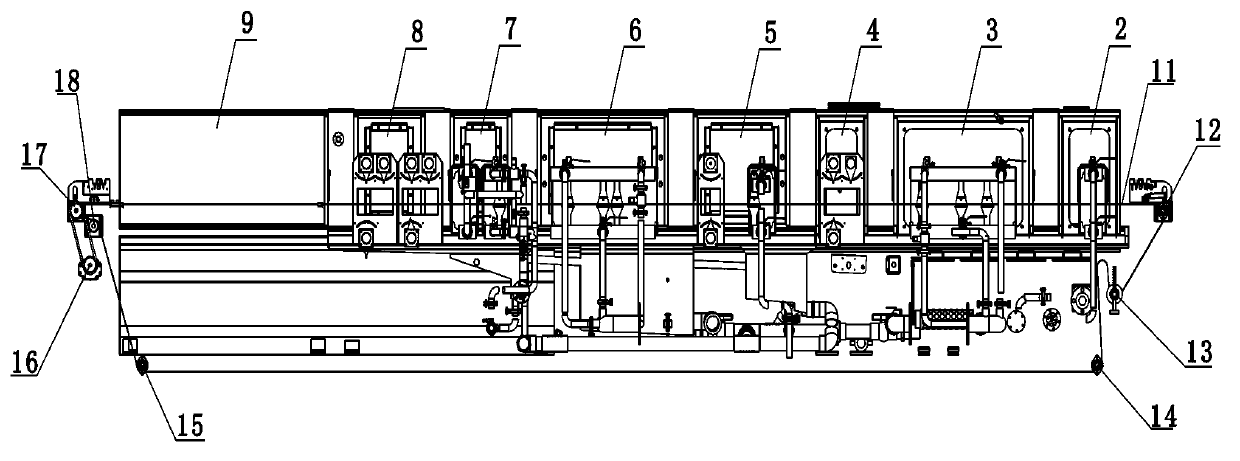

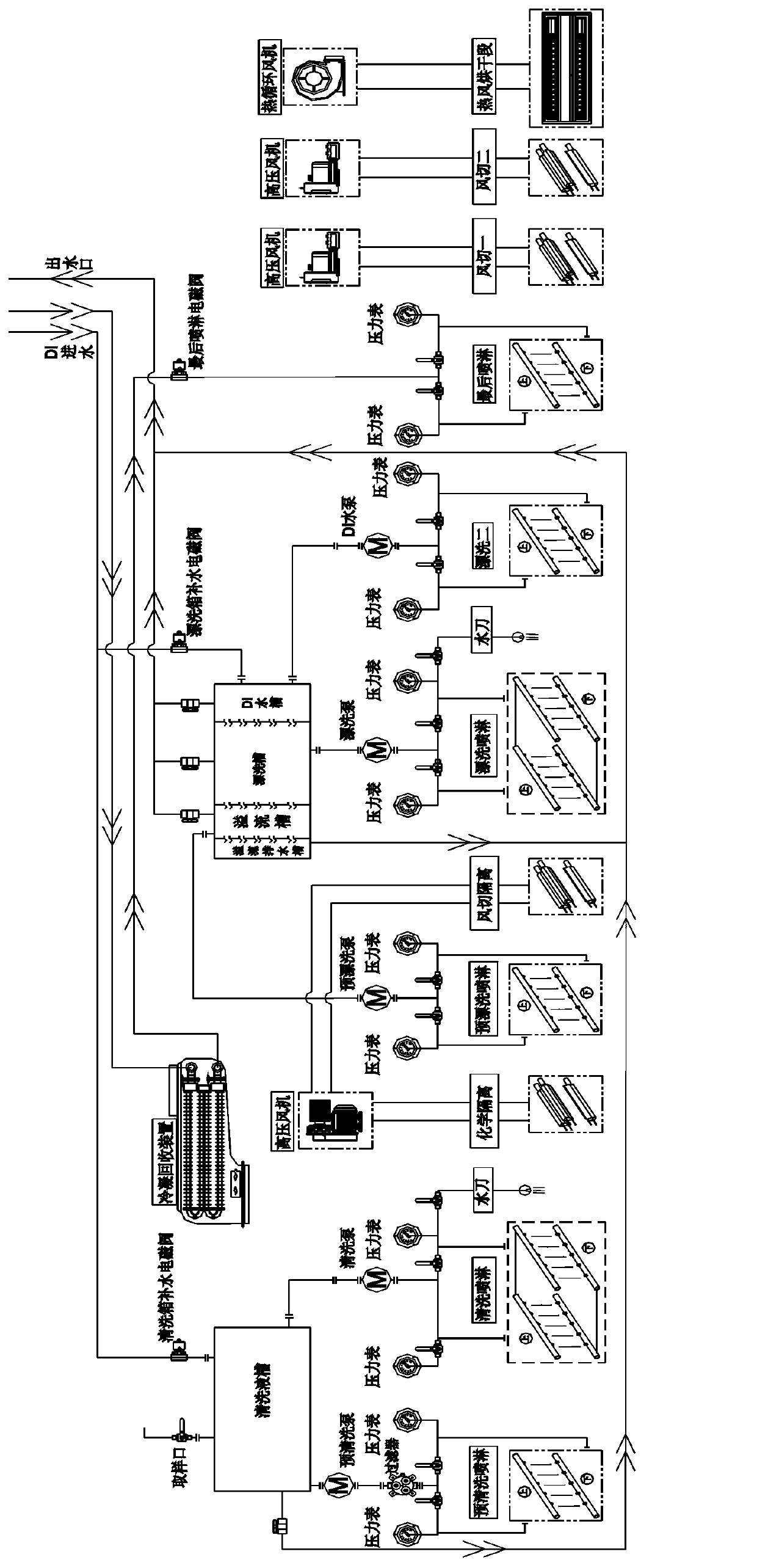

[0021] See figure 1 , figure 2 , image 3 as shown, figure 1 It is a schematic diagram of the overall structure of the PCBA online cleaning machine of the present invention; figure 2 It is a schematic diagram of the internal structure of the PCBA online cleaning machine of the present invention; image 3 It is a schematic diagram of the fluid pipeline of the PCBA online cleaning machine of the present invention. The PCBA online cleaning machine of the present invention is as follows to the cleaning procedure of PCBA: By sequentially cleaning the PCBA board through the above process, the cleaning and rinsing of the PCBA board can be made more comprehensive, and the quality of cleaning and rinsing can be effectively improved.

[0022] Wherein said PCBA online cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com