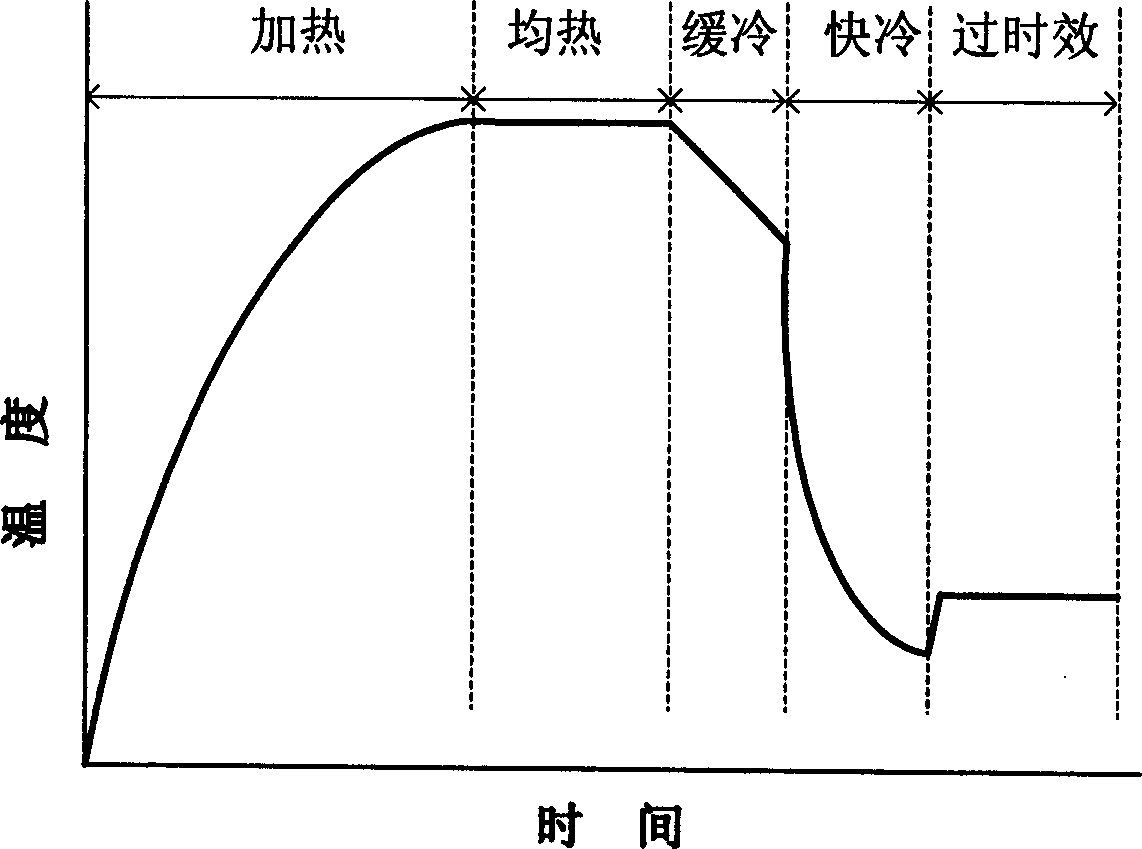

Simulating device for strip steel continuous annealing process

A simulation device and annealing technology, applied in the direction of instruments, analyzing materials, testing metals, etc., can solve the problems of cooling speed, which can only reach 50℃/s, and high cost of introduction, achieve high cooling speed and reduce the influence of cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

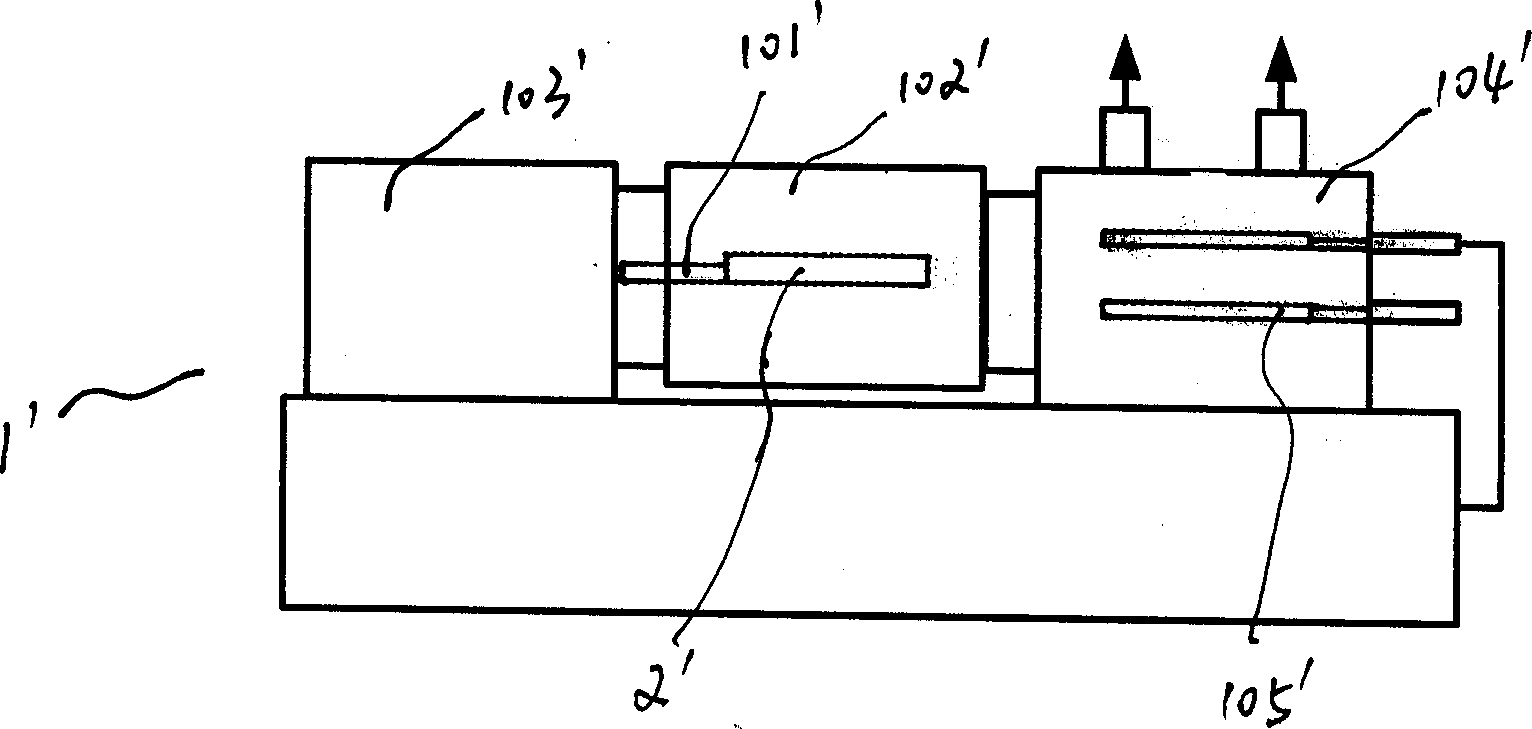

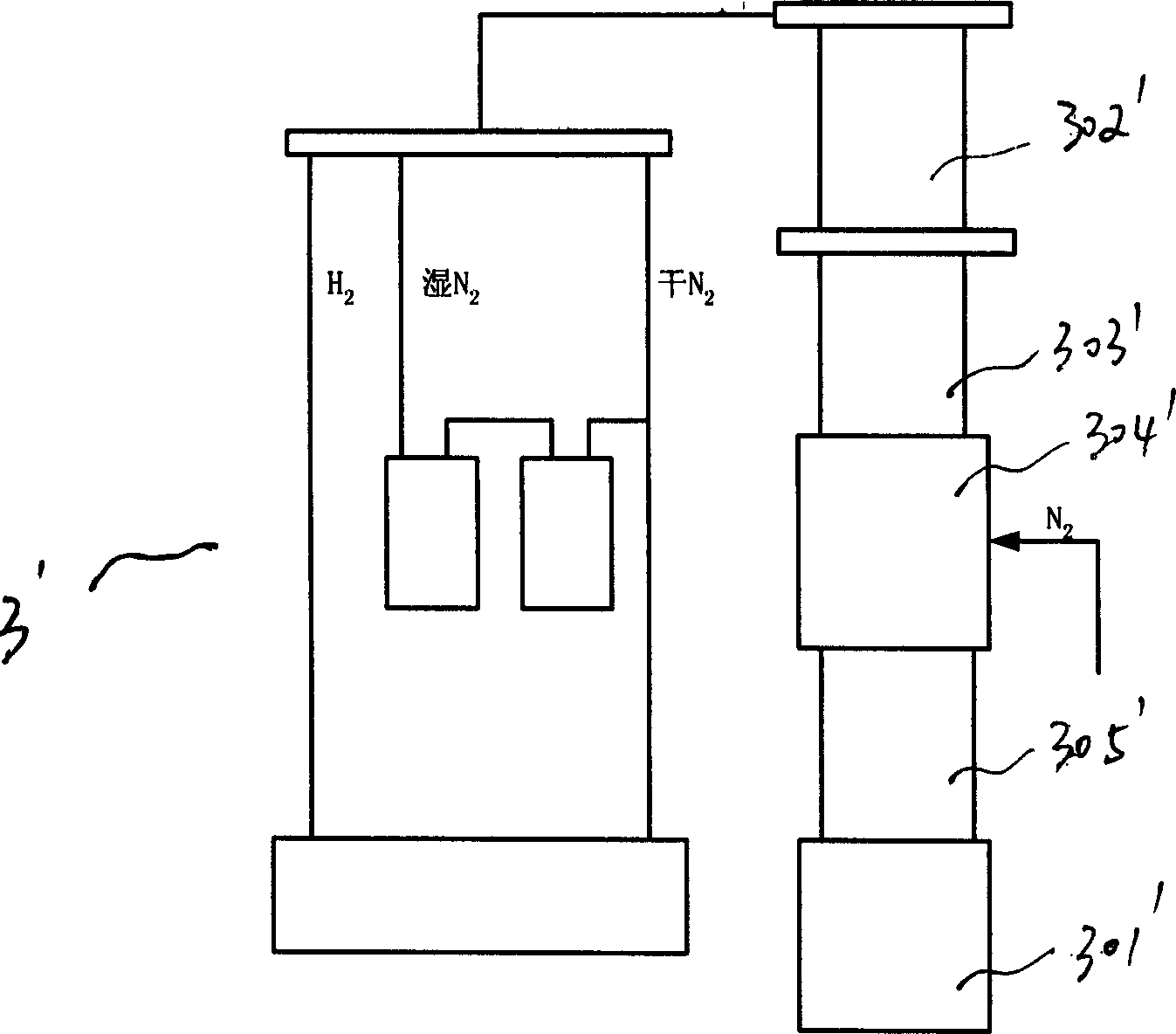

[0025] based on the following Figure 4 and Figure 5 , illustrating a preferred embodiment of the present invention.

[0026] Such as Figure 4 Shown, is the block diagram of strip continuous annealing simulation device 1 provided by the present invention, as Figure 5 Shown is a schematic structural view of the strip continuous annealing simulation device 1 provided by the present invention. The strip continuous annealing simulation device 1 includes a heating chamber 102 installed sequentially from top to bottom, a soaking chamber 103, an overaging chamber 105, and a cooling chamber. The chamber 104 and the loading and unloading sample chamber 101 also include a sample transmission device;

[0027] The heating chamber 102, the soaking chamber 103 and the overaging chamber 105 are made of a single liner, which are integrated from top to bottom, and shrinkage is provided between the heating chamber 102, the soaking chamber 103 and the overaging chamber 105. type channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com