Metal thermal spraying production line

A production line, metal heat technology, applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the difficulty of ensuring the internal and appearance quality of the coating, lack of cleaning procedures and environmental control, and environmental pollution of thermal spraying and other problems, to achieve good processing effect and economic benefits, simple and efficient design, and fast and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

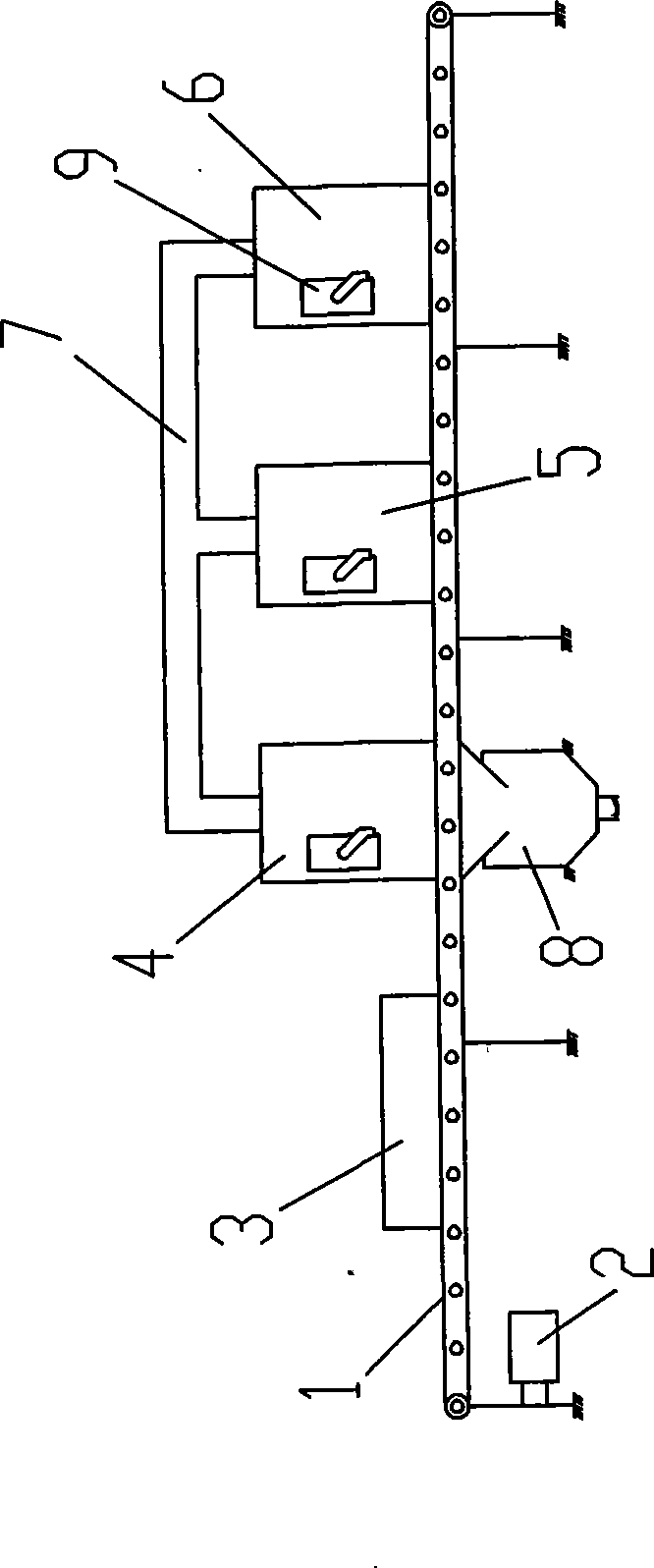

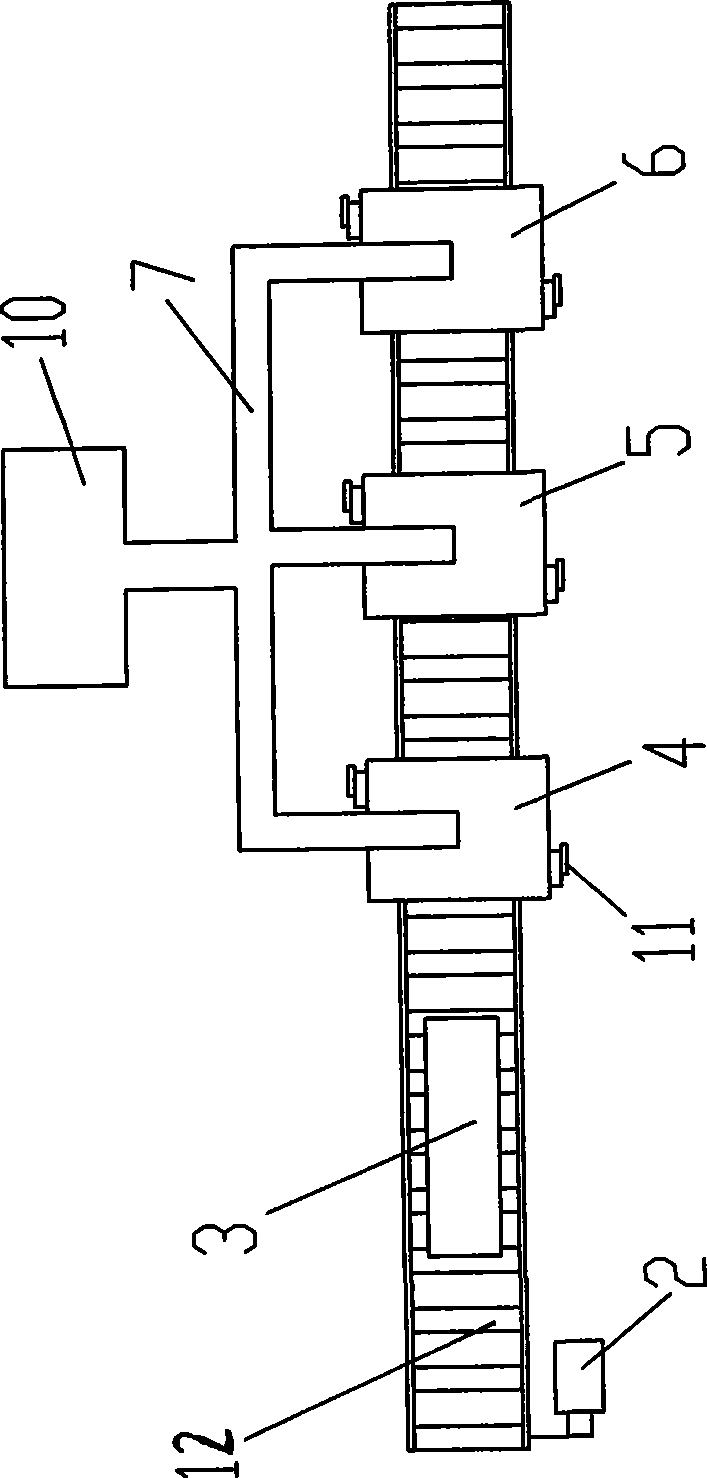

[0013] Metal thermal spraying production line, including platform 1, a rolling roller table 12 for running workpieces on the platform, a drive motor 2 for driving the roller table, a sandblasting room 4, and a cleaning room that are installed across the roller table from front to back 5 and thermal spraying chamber 6; below the sandblasting chamber there is a sand tank 8 communicating with the sandblasting chamber; above the sandblasting chamber, the cleaning chamber and the thermal spraying chamber, the dust suction pipe 1 communicates with the dust removal equipment 10. Each operation is carried out in the corresponding operation room; the waste gas, waste residue, and dust generated by each operation are discharged after centralized dust removal treatment through the dust suction pipe.

[0014] The roller table 12 is driven by a motor plus a gear, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com