Testing device for odors, VOC and floating harmful substances

A technology of harmful substances and testing devices, which is applied in the field of volatile organic compound testing equipment, can solve the problems of affecting the testing accuracy, affecting the testing accuracy, and not being able to purify the gas, so as to achieve the effect of improving the testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

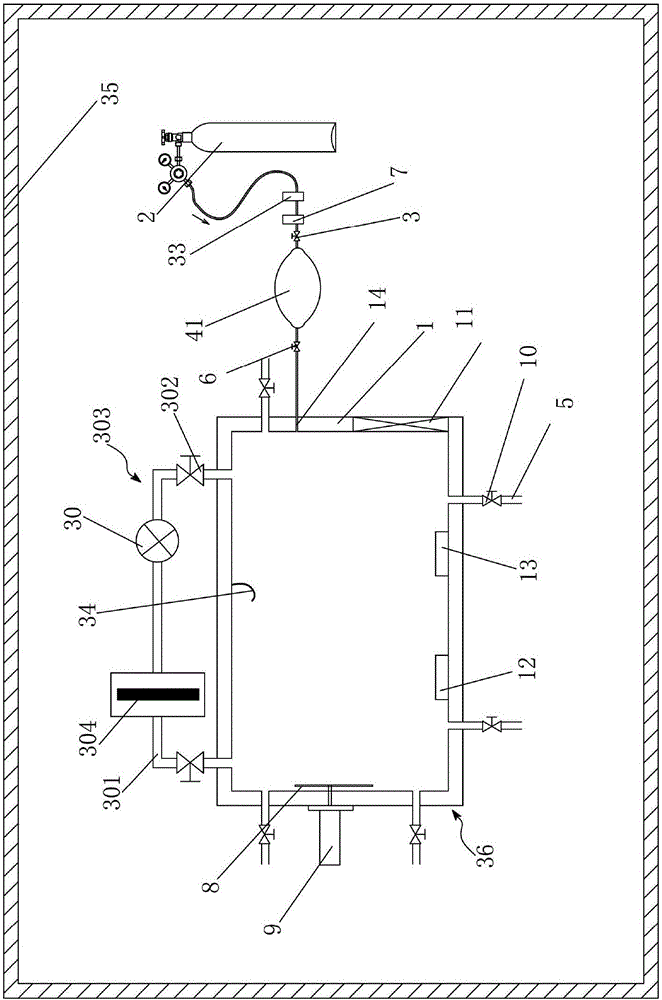

[0031] Please refer to figure 1 , Embodiment 1 of the present invention provides a kind of smell, VOC and floating harmful substance testing device, comprise constant temperature and / or constant humidity clean room 35, install at least one smell in described constant temperature and / or constant humidity clean room 35 , VOC test cabin 36, this smell, VOC test cabin 36 comprises cabin body 1, is provided with at least one smell sampling port 5 on cabin body 1, and cabin body 1 is connected with and is used for gas sampling process to cabin body 1 interior. Volume compensation to prevent the polluted gas outside the cabin from entering the gas compensation device in the cabin 1 due to the pressure difference. The gas compensation device is located outside the cabin 1 and also includes an external circulation filter device 30 installed outside the cabin 1. The external circulation filtering device 30 includes an external circulation pipeline 301 communicated with the interior of t...

Embodiment 2

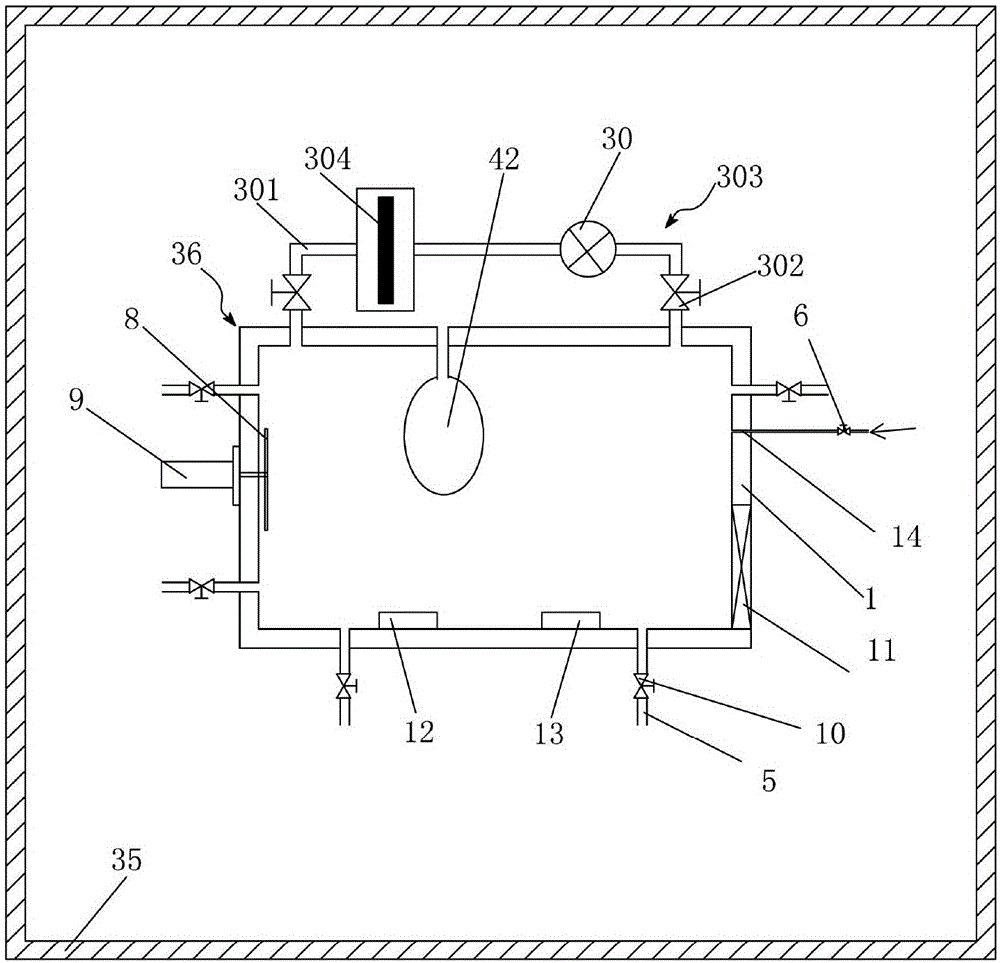

[0051] Please refer to figure 2 , the second embodiment of the present invention provides another odor, VOC and floating harmful substances testing device, including constant temperature and / or constant humidity clean room 35, at least one of which is installed in the constant temperature and / or constant humidity clean room 35 Smell, VOC test cabin 36, this smell, VOC test cabin 36 comprises cabin body 1, and cabin body 1 is provided with at least one smell sampling mouth 5, and cabin body 1 is connected with the gas sampling process to the inside of cabin body 1. The gas volume compensation prevents the polluted gas outside the cabin from entering the gas compensation device in the cabin 1 due to the pressure difference. The odor, VOC and floating harmful substance testing device of the second embodiment of the present invention is the same as the odor, VOC and floating harmful substances of the first embodiment above. Most of the structures of the material testing devices a...

Embodiment 3

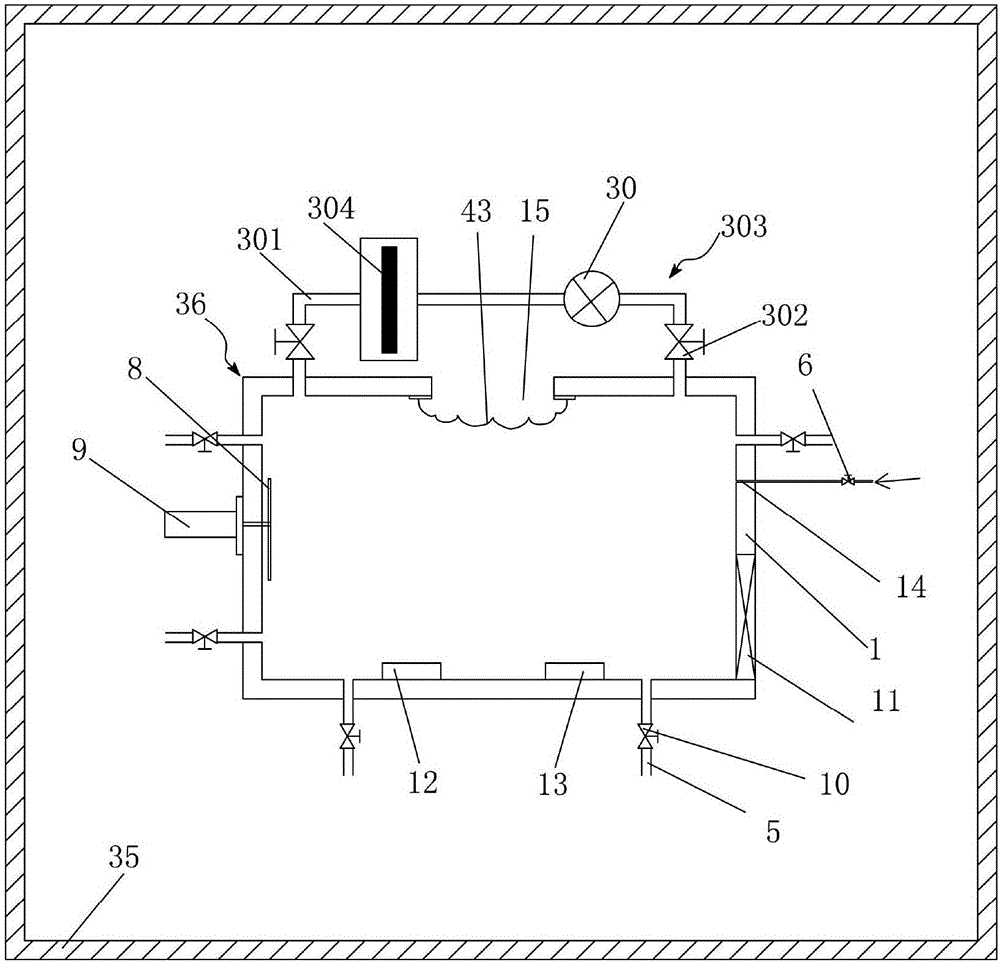

[0056] Please refer to image 3 , the third embodiment of the present invention provides another odor, VOC and floating harmful substances testing device, including constant temperature and / or constant humidity clean room 35, at least one of which is installed in the constant temperature and / or constant humidity clean room 35 Smell, VOC test cabin 36, this smell, VOC test cabin 36 comprises cabin body 1, and cabin body 1 is provided with at least one smell sampling mouth 5, and cabin body 1 is connected with the gas sampling process to the inside of cabin body 1. The gas volume compensation prevents the polluted gas outside the cabin from entering the gas compensation device in the cabin 1 due to the pressure difference. The odor, VOC and floating harmful substance testing device of the third embodiment of the present invention is the same as the odor, VOC and floating harmful substances of the first embodiment above. Most of the structures of the material testing devices are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com