Train wheel set laser cleaning machine and train wheel set cleaning method

A technology for laser cleaning and train wheels, which is applied to cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc. The effect of labor cost, high degree of automation and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

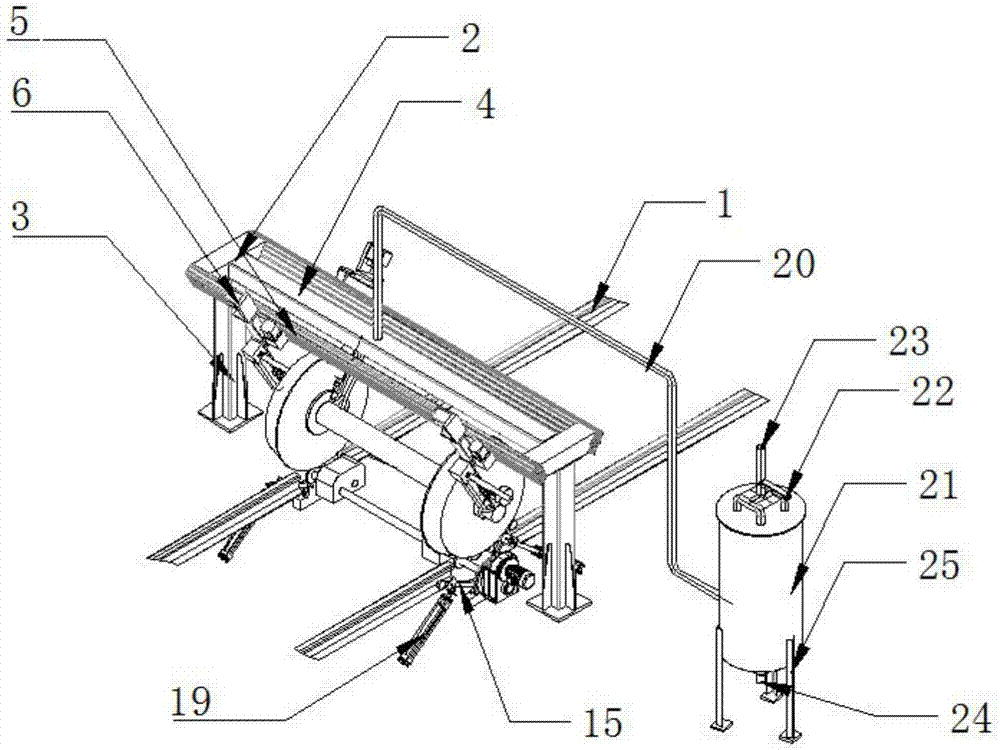

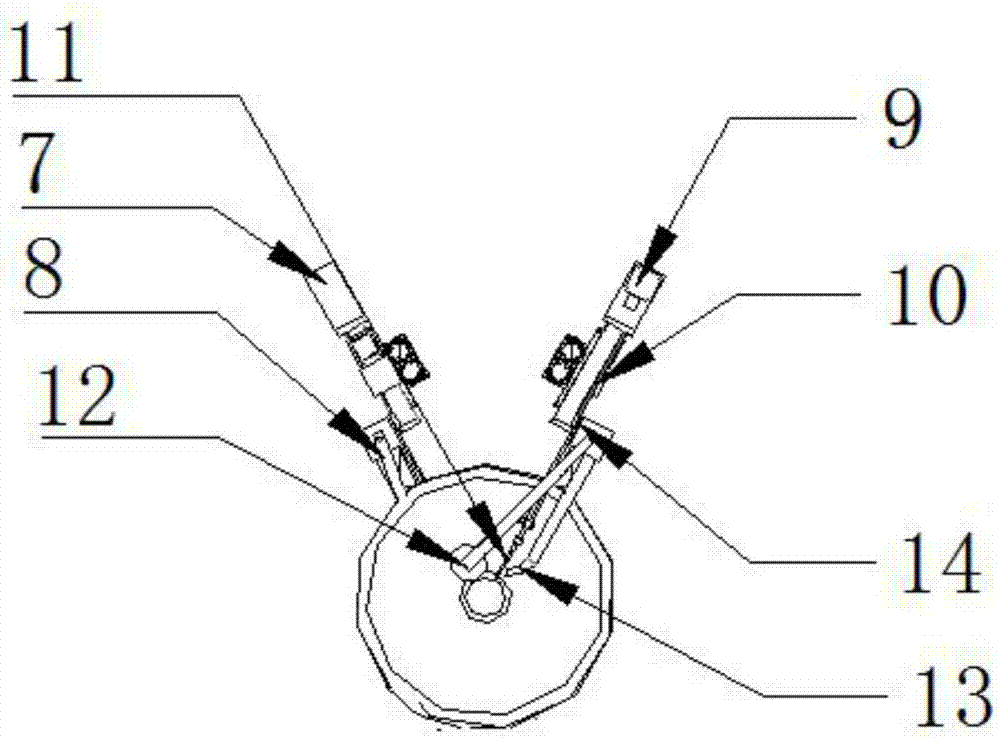

[0027] Embodiment 1: The structure of the train wheel set laser cleaning machine

[0028] A train wheel laser cleaning machine, including a cleaning room, a train wheel laser cleaning device is set in the cleaning room, and a left lifting door and a right lifting door are arranged on the cleaning room to protect safety and seal smoke and dust. The device includes a truss 2, a wheel set limit driving unit, a waste discharge unit and a wheel set cleaning unit slidingly connected with the truss. In this embodiment, the cleaning room is also provided with an observation window and an inspection door. If the equipment in the cleaning room is found to be faulty, the inspection door can be opened for inspection.

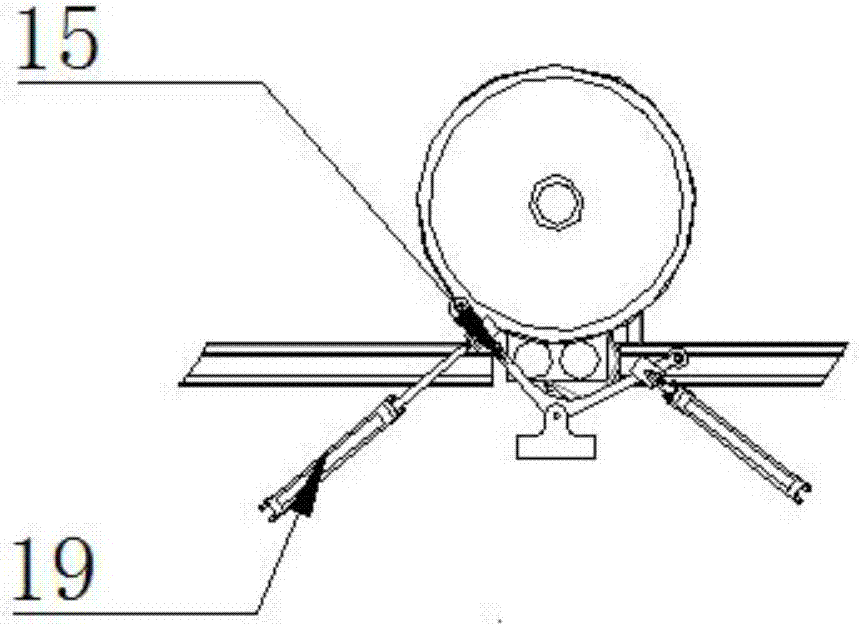

[0029] like figure 1 As shown, the truss 2 of the train wheel set laser cleaning machine is composed of two upright columns 3 placed on both sides of the wheel set track 1 and a beam 4 between the two columns, the beam 4 is perpendicular to the wheel set track 1; the truss...

Embodiment 2

[0033] Embodiment 2: a kind of method for laser cleaning of train wheels of the present invention

[0034] The method for cleaning the train wheels by using the train wheel laser cleaning machine in the embodiment may further comprise the steps:

[0035] (1) After placing the train wheels on the track, open the right lifting door of the cleaning room, extend the left drive cylinder, retract the right drive cylinder, push the left side of the push rod to lift, and push the wheels to the tugboat with external force , after confirming that there is no abnormality, close the lifting door;

[0036] (2) Under the control of the automatic mode of the laser cleaning machine for train wheels, press the "auto start" button, the wheels rotate, each cleaner slides to the corresponding position, the cleaning module slides down, and the laser, cleaning wheel, and mist suction port automatically start working according to the program; In manual mode, first turn on the electrical control swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com