Bulk production method of micro-fluidic chip

A microfluidic chip, mass production technology, applied in the direction of coating, etc., can solve the problem that microfluidic chips cannot be produced in batches, and achieve the effect of fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

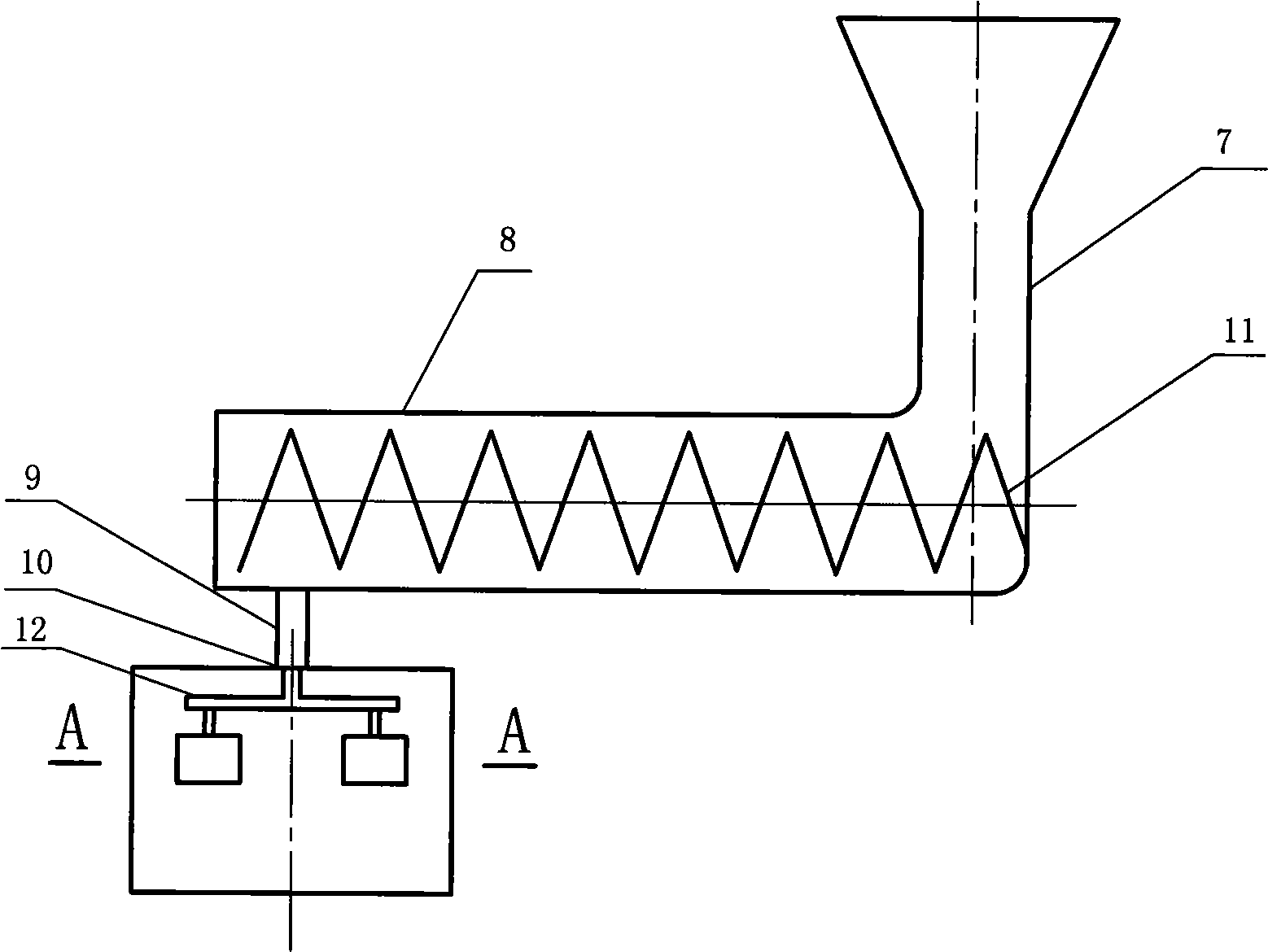

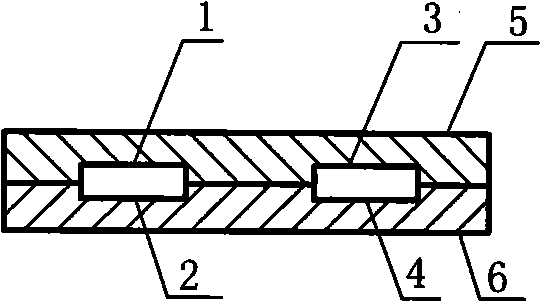

[0028] Such as figure 1 it is good figure 2 As shown, the mass production method of the microfluidic chip of the present invention uses a precision electric injection molding machine and a mold. This injection molding machine comprises: vertical feeding cylinder 7, horizontal material cylinder 8 and discharge port 9, and screw rod 11 is housed in the horizontal material cylinder 8, mold comprises: movable mold 5 and static mold 6 and mold core, and this mold core comprises: Left moving core part 1, left static core part 2, right moving core part 3 and right static core part 4. The discharge port 9 is aligned with the injection port 10 between the movable mold 5 and the static mold 6 .

[0029] The batch production method of the microfluidic chip of the present invention comprises the following steps:

[0030] (a) Choose a mold core made of cemented carbide material with a surface polishing degree of 0.02-0.06 microns. The mold core is J05 hard alloy steel with a hardness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com