Moisture absorption hot air circular drying oven

A hot air circulation oven and hot air circulation technology are applied in the fields of pharmacy, chemical industry and oven, which can solve problems such as the effective use of unfavorable heat and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

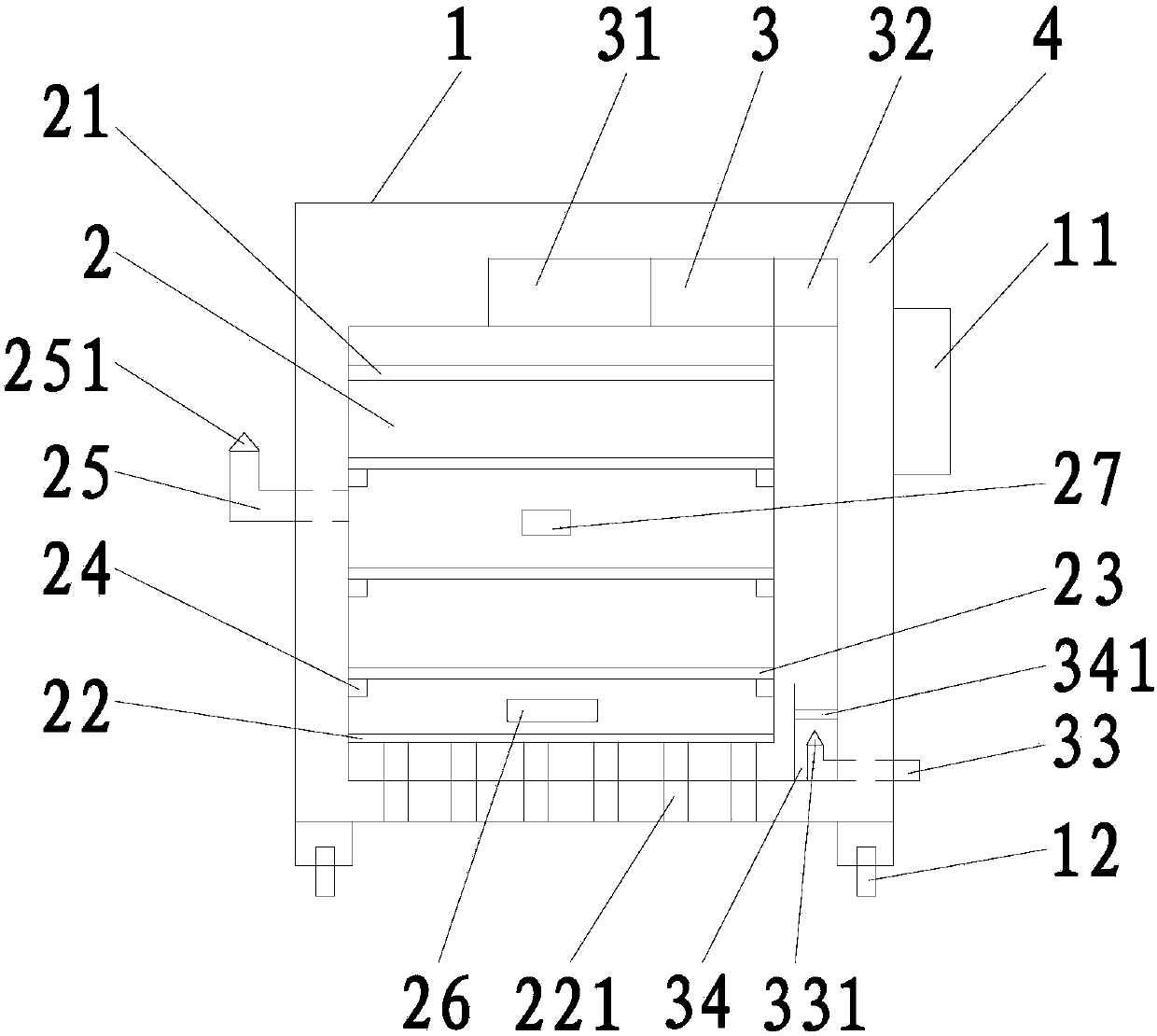

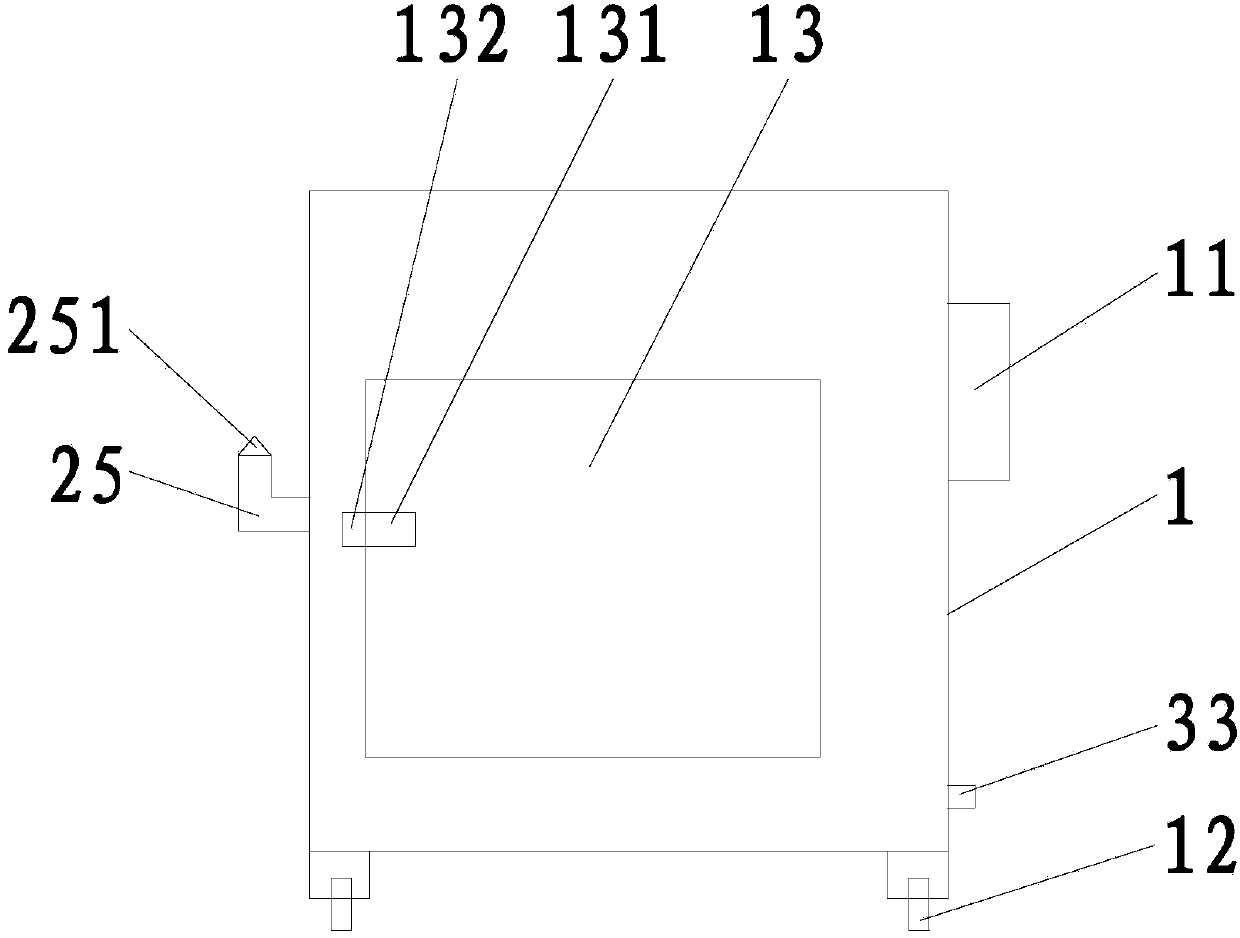

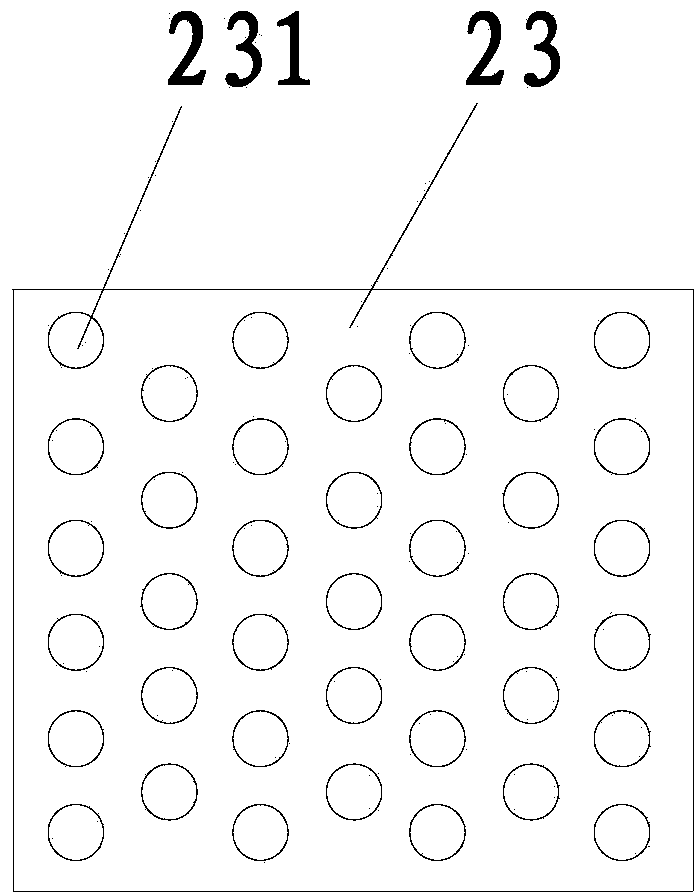

[0017] refer to figure 1 , figure 2 , image 3 with Figure 4 , a hygroscopic hot air circulation oven of the present invention comprises a box body 1, a drying chamber 2, a hot air circulation pipeline 3, the drying room 2 and the hot air pipeline 3 are in the box body 1, the box body 1, the drying room 2, The gap between the hot air pipes 3 is the insulation layer 4. The hot air circulation pipe 3 is connected to the top plate 21 of the drying chamber and the bottom plate 22 of the drying chamber. Air holes 231, the lower part of the bottom plate 22 of the drying chamber has a support column 221 connected to the box body 1, a circulation fan 32 is arranged in the hot air circulation pipeline 3, and a moisture absorption device 31 is arranged in the hot air circulation pipeline 3, and the moisture absorption device 31 is provided by the air inlet cavity 311 and a drying chamber 312. There are several synergistic plates 313 in the drying chamber 312. There are several desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com