Lumber drying equipment and method of drying lumber by using equipment

A technology for wood drying and drying equipment, which is applied to the combination of methods to dry solid materials, dry solid materials, local stirring dryers, etc., can solve the problems of inability to perform drying treatment, large ultrasonic energy loss, low efficiency, etc., to reduce drying. Defects, fast drying, uniform treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Take a eucalyptus wood segment with a size of 200mm (length) × 100mm (width) × 40mm (thickness) and carry out ultrasonic drying treatment to dry the eucalyptus wood

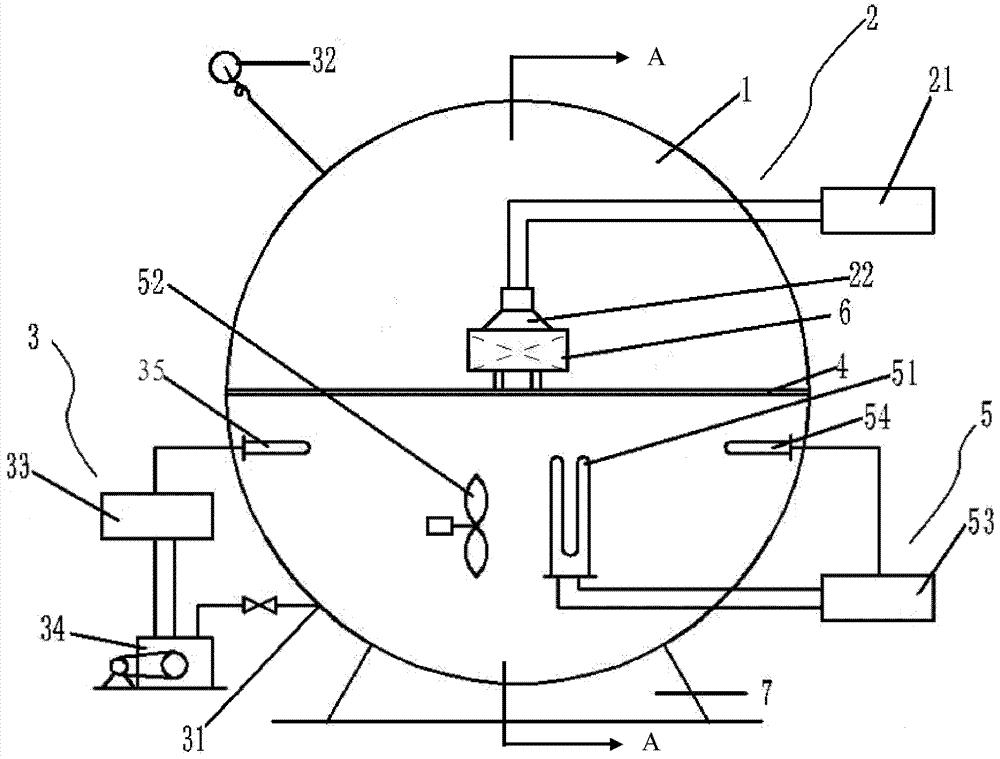

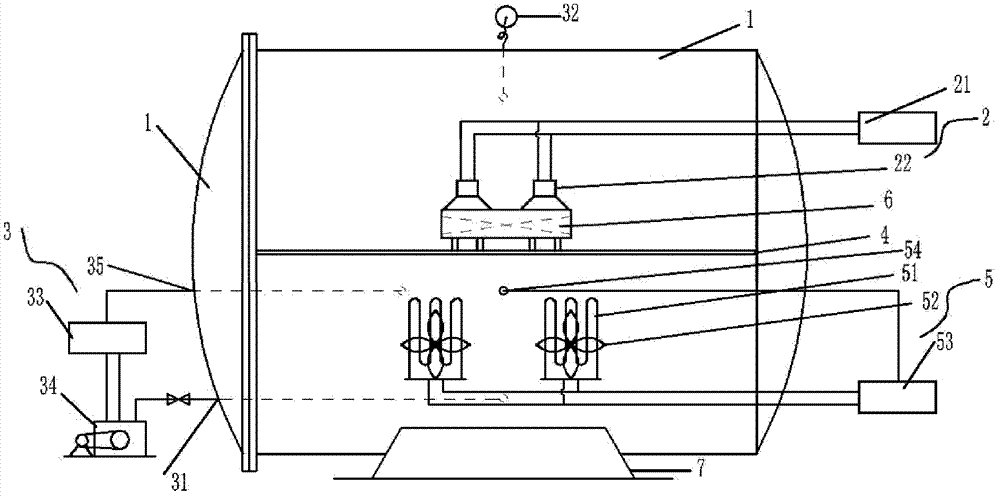

[0069] 1. Place a piece of eucalyptus wood section on the loading assembly 4 so that the thickness of the eucalyptus wood section is consistent with the radial (height) direction of the wood drying chamber 1, that is, place the eucalyptus wood section on the loading assembly 4 The height is 40mm.

[0070] 2. Place 2 ultrasonic transducers 22 in the plane perpendicular to the length and width of the eucalyptus wood section in the thickness direction of the eucalyptus wood section, and make the ultrasonic transducer 22 and the upper surface of the eucalyptus wood section 6 direct contact.

[0071] 3. Set the power and frequency of the ultrasonic transducer 22 according to the area of the plane formed by the length and width direction of the wood to be treated, and adjust the ultrasonic generator 21 so tha...

Embodiment 2

[0078] Except that the thickness of the eucalyptus wood section is 20mm, the power of each ultrasonic transducer 22 is 150W, and the ultrasonic power applied on each square centimeter of wood section is 1.5W, and the temperature in the cavity of the wood drying chamber 1 is 40°C. The rate is 5° C. / min, and the absolute pressure in the cavity of the wood drying chamber is 0.08 MPa, and the rest are the same as in Example 1.

[0079] The wood drying time and drying rate are shown in Table 1.

Embodiment 3

[0081] Except that the temperature in the cavity of the wood drying chamber 1 is 50°C, the temperature rise rate is 15°C / min, the absolute pressure is 0.03MPa, the power of each ultrasonic transducer is 300W, and the frequency is 28kHz. Ultrasonic power is except 3W, all the other are identical with embodiment 1.

[0082] The wood drying time and drying rate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com