Anti-aging PVC (Polyvinyl Chloride) coating canopy plus material and manufacturing process thereof

A kind of canopy fabric and manufacturing process technology, applied in lamination, layered products, lamination devices, etc., can solve the problems of heavy odor, affecting experience, and lack of purification of odor, so as to prevent odor, simple structure, and easy to work The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

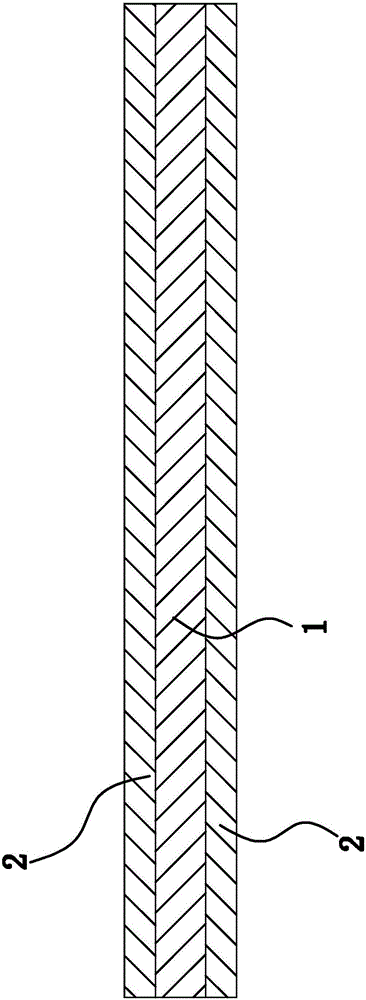

[0064] Such as figure 1 As shown, the anti-aging PVC coated canopy fabric is composed of base fabric 1 and two layers of PVC film 2 respectively located on the upper side and lower side of base fabric 1, and the PVC film 2 and base fabric 1 are bonded at a high temperature of 190 °C together. Among them, the base fabric 1 is a 20×20 biaxial base fabric 1 made of 1000D×1000D polyester filaments through warping and weaving; the PVC film 2 is made of the following raw materials by weight: PVC resin powder 100; Diantimony oxide 3; Dioctyl phthalate 50; Dimethyl adipate 3; Titanium dioxide 3; Stabilizer 3; Soybean oil 2; Calcium carbonate 20; Anti-aging, odor absorption and other functions.

[0065] It is further illustrated that the opposite side surfaces of the two PVC films 2 are subjected to matte treatment; the surface of the fabric formed by the above-mentioned lamination is coated with a fluorosilicon finishing agent (the fluorosilicon finishing agent will penetrate into t...

Embodiment 2

[0082] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the PVC film 2 and the base fabric 1 are bonded together at a high temperature of 195°C. PVC film 2 is prepared from the following raw materials in parts by weight: PVC resin powder 100; antimony trioxide 3.5; dioctyl phthalate 55; dimethyl adipate 3.5; titanium dioxide 4; stabilizer 5; soybean oil 3; calcium carbonate 20; activated carbon powder 4.

[0083] The PVC film 2 calendering process includes the following steps: D. Weigh the ingredients and stir and mix: pour the ingredients into the mixer after weighing and stir, control the stirring temperature to 105°C, and the stirring speed to 300r / min; E, Banbury: control the temperature 150°C; F, two-roller plasticizing: the roll distance is controlled at 8mm, and the control temperature is 190°C; G, filtration: the mesh number of the filter is 80 mesh; H, four-roller calendering: the temperature is ...

Embodiment 3

[0086] The structure and principle of the third embodiment are basically the same as those of the first embodiment, except that the PVC film 2 and the base fabric 1 are bonded together at a high temperature of 200°C. PVC film 2 is prepared from the following raw materials in parts by weight: PVC resin powder 100; antimony trioxide 4; dioctyl phthalate 60; dimethyl adipate 4; titanium dioxide 5; stabilizer 6; soybean oil 4; calcium carbonate 20; activated carbon powder 5.

[0087] The PVC film 2 calendering process includes the following steps: D. Weigh the ingredients and stir and mix: pour the ingredients into the mixer after weighing and stir, control the stirring temperature to 105°C, and the stirring speed to 300r / min; E, Banbury: control the temperature 150°C; F, two-roll rolling wheel plasticization: the roll distance is controlled at 10mm, and the control temperature is 200°C; G, filtration: the mesh number of the filter mesh is 90 mesh; H, four-roll calendering: the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com