High-temperature-resistant nylon PA66T material and preparation method thereof

A technology of high temperature resistance and nylon, which is applied in the field of polymer synthesis, can solve the problems that cannot explain the high temperature resistance of nylon, the difficulty of production and processing, and poor fluidity, etc., and achieve the effect of low equipment cost, reduced environmental pressure, and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

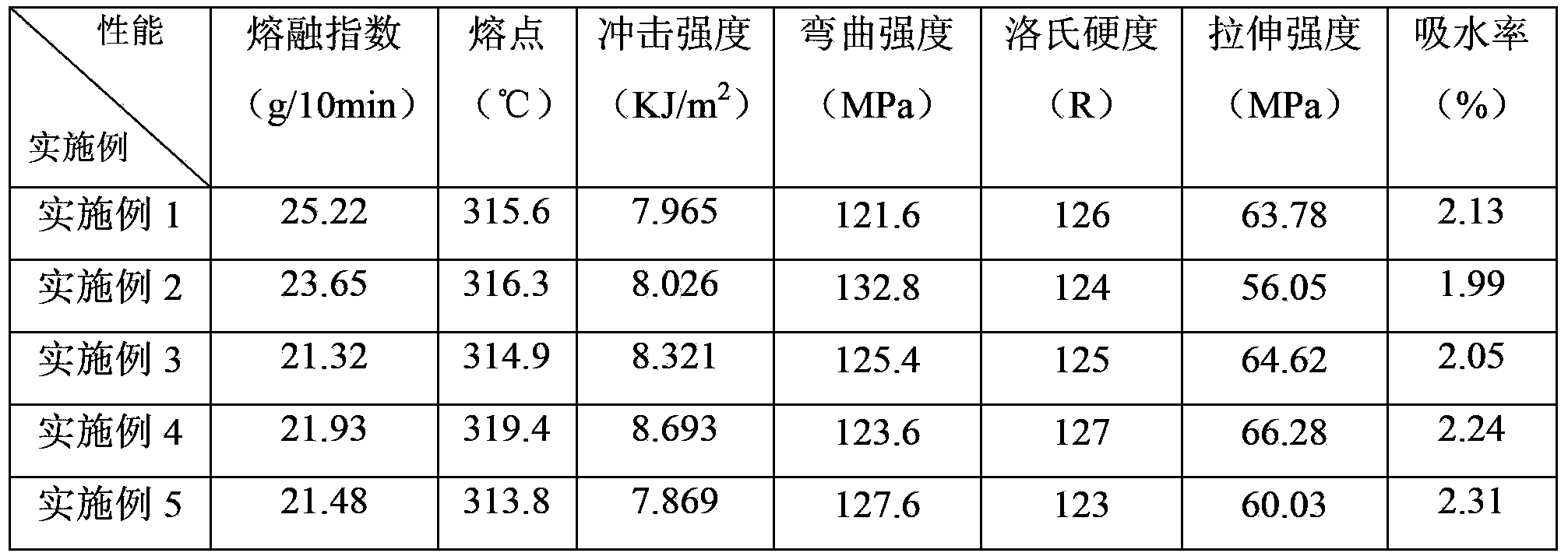

Examples

Embodiment 1

[0045] (1) Weigh 1827.43g (11.00mol) of terephthalic acid, 1315.26g (9.00mol) of adipic acid, 2231.232g (19.20mol) of hexamethylenediamine, 1.2896g (0.015mol) of sodium hypophosphite, and mix Evenly pour it into the polymerization reactor, inject 4.50kg of deionized water (250mol) and nucleating agent barium sulfate 8.1687g (0.035mol) into the reactor, turn on the stirring device, the stirring speed is 60r / min, fill in Vacuumize with nitrogen, repeat 3 times, remove the air reserved in the kettle, and reserve 0.01MPa nitrogen as protective gas.

[0046] (2) Raise the temperature in the reactor to 130°C by circulating heat transfer oil and keep it warm for 2.5 hours, so that the polymerized monomers are completely dissolved in the solvent deionized water.

[0047](3) After the heat preservation is over, continue to increase the temperature in the reactor until the pressure in the reactor is 2.3MPa, maintain the pressure for 2 hours, and increase the temperature of the reactor w...

Embodiment 2

[0049] (1) Weigh 1873.116g (11.275mol) of isophthalic acid, 1348.142g (9.225mol) of adipic acid, 2298.924g (19.7825mol) of hexamethylenediamine, 4.25g (0.025mol) of calcium hypophosphite, and mix well And pour it into the polymerization reactor, inject 4.86kg of deionized water (270mol) and nucleating agent talc powder 11.7387g (0.045mol) into the reactor, turn on the stirring device, the stirring speed is 60r / min, and fill with carbon dioxide Carry out vacuuming, repeat 3 times, remove the air reserved in the kettle, and reserve 0.02MPa carbon dioxide as a protective gas.

[0050] (2) The temperature in the reactor was raised to 150°C by circulating the heat transfer oil and kept for 2.0 hours, so that the polymerized monomers were completely dissolved in the solvent deionized water.

[0051] (3) After the heat preservation is over, continue to increase the temperature in the reactor until the pressure in the reactor is 2.5MPa, maintain the pressure for 1.5 hours, and raise t...

Embodiment 3

[0053] (1) Weigh 1918.8015g (11.55mol) of phthalic acid, 1381.023g (9.45mol) of adipic acid, 2367.1977g (20.37mol) of hexamethylenediamine, 2.0414g (0.020mol) of potassium hypophosphite, and mix Evenly pour it into the polymerization reactor, inject 5.22kg deionized water (290mol) and nucleating agent silicon dioxide 3.0042g (0.05mol) into the reactor, turn on the stirring device, the stirring speed is 60r / min, and fill Inject argon for vacuuming, repeat 3 times, remove the air reserved in the kettle, and reserve 0.03MPa argon as a protective gas.

[0054] (2) The temperature in the reactor was raised to 145°C by circulating heat transfer oil and kept for 2.0 hours, so that the polymerized monomers were completely dissolved in the solvent deionized water.

[0055] (3) After the heat preservation is over, continue to increase the temperature in the reactor until the pressure in the reactor is 2.5MPa, maintain the pressure for 1.5 hours, and raise the temperature of the reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com