Ultra-flexible polyurethane acrylate resin and liquid-state optical adhesive composition thereof

A technology of urethane acrylate and hydroxyalkyl acrylate, which is applied in the fields of ultra-flexible urethane acrylate resin, liquid optical adhesive composition, and acrylic resin, and can solve problems such as large shrinkage, low bonding strength, and poor weather resistance. Achieve the effects of small shrinkage, good flexibility and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of super flexible polyurethane acrylate oligomer, the steps are:

[0029] Add 91.11g of 3500 molecular weight liquid hydroxyl-terminated polybutadiene rubber (hydroxyl content is 0.55mmol / g) and 0.1g of nitroxide radical polymerization inhibitor in the reaction vessel, dehydrate in vacuum for 1 hour at 100~105°C, cool to 60°C, add 80g of cyclohexane, stir well, add 6.02g of 1,6-hexamethylene diisocyanate, stir well, add tetraisooctyl titanate catalyst 0.04g, fill with high-purity nitrogen protection and stir well, heat up to 80 ~85°C, keep warm and reflux for 3 hours, cool down to 65~70°C; then add 2.87g of hydroxypropyl acrylate, heat up to 80~85°C, keep warm and reflux for 4 hours; wait until the temperature in the reaction vessel drops to 50°C , adding 0.5% absolute ethanol to react for 20 minutes, vacuum distillation to remove the solvent, and obtain super-flexible polyurethane acrylate oligomer.

Embodiment 2

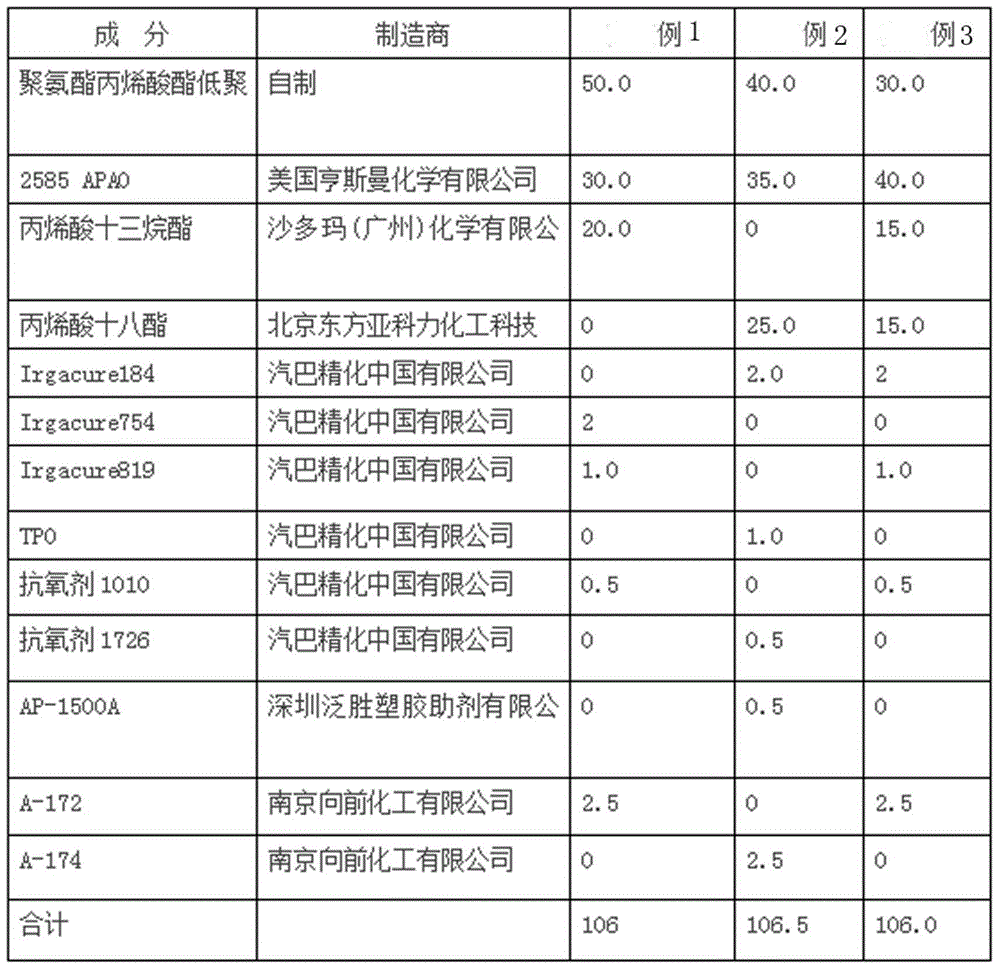

[0031] The preparation method of the liquid optical adhesive composition can be combined with the ingredients shown in Table 1 and the shown quality to obtain the liquid optical adhesive compositions of 2, 3, and 4,

[0032] Table 1

[0033]

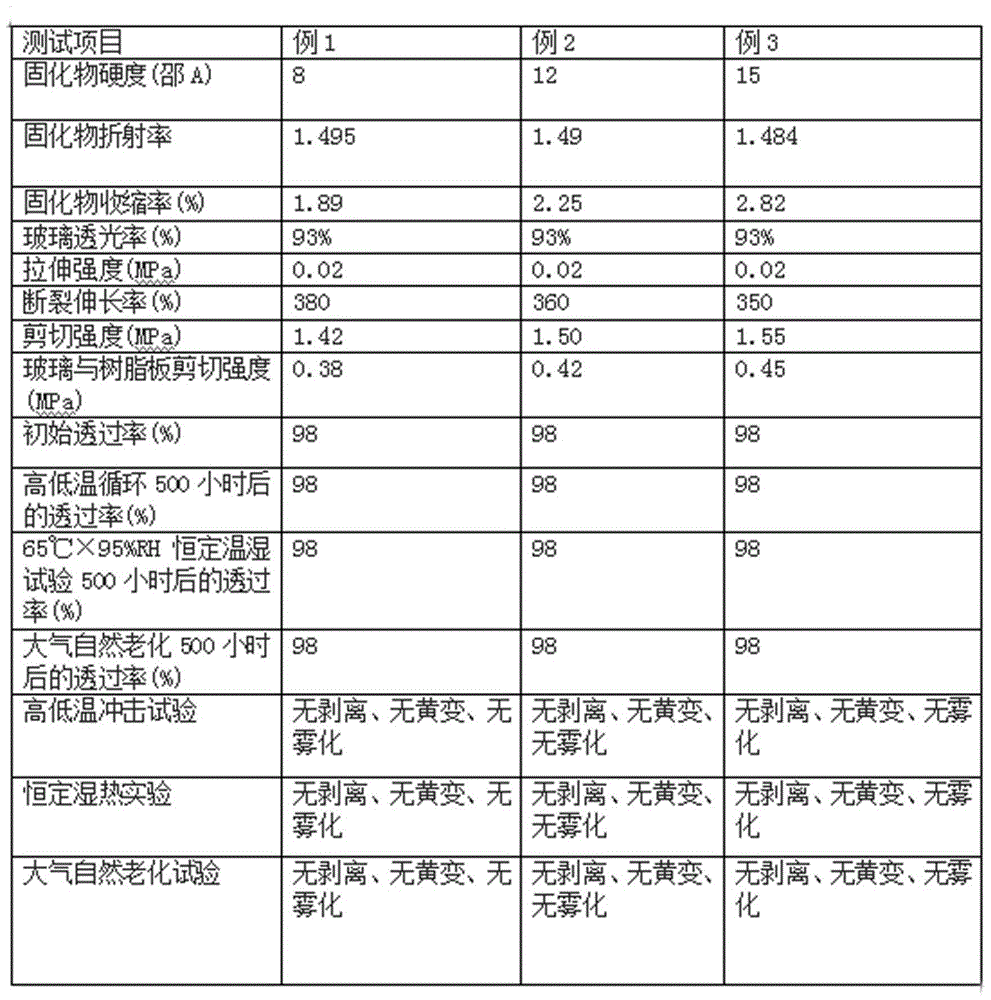

[0034]The liquid optical adhesive compositions prepared in Examples 1, 2, and 3 have no air bubbles in any of the high and low temperature impact tests, constant temperature and humidity tests, and atmospheric natural aging tests, and the physical and chemical properties are analyzed by the following analytical method, The results are shown in Table 2.

[0035] Table 2

[0036]

[0037] Shrinkage rate is measured according to GB1465-2005 liquid density and cured product density, calculated from the volume ratio of the two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com