Polyaniline metal anticorrosion water-soluble industrial coatings

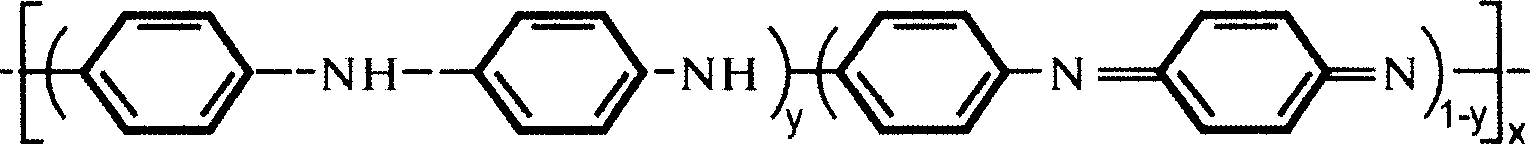

A metal anti-corrosion, polyaniline technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, epoxy coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

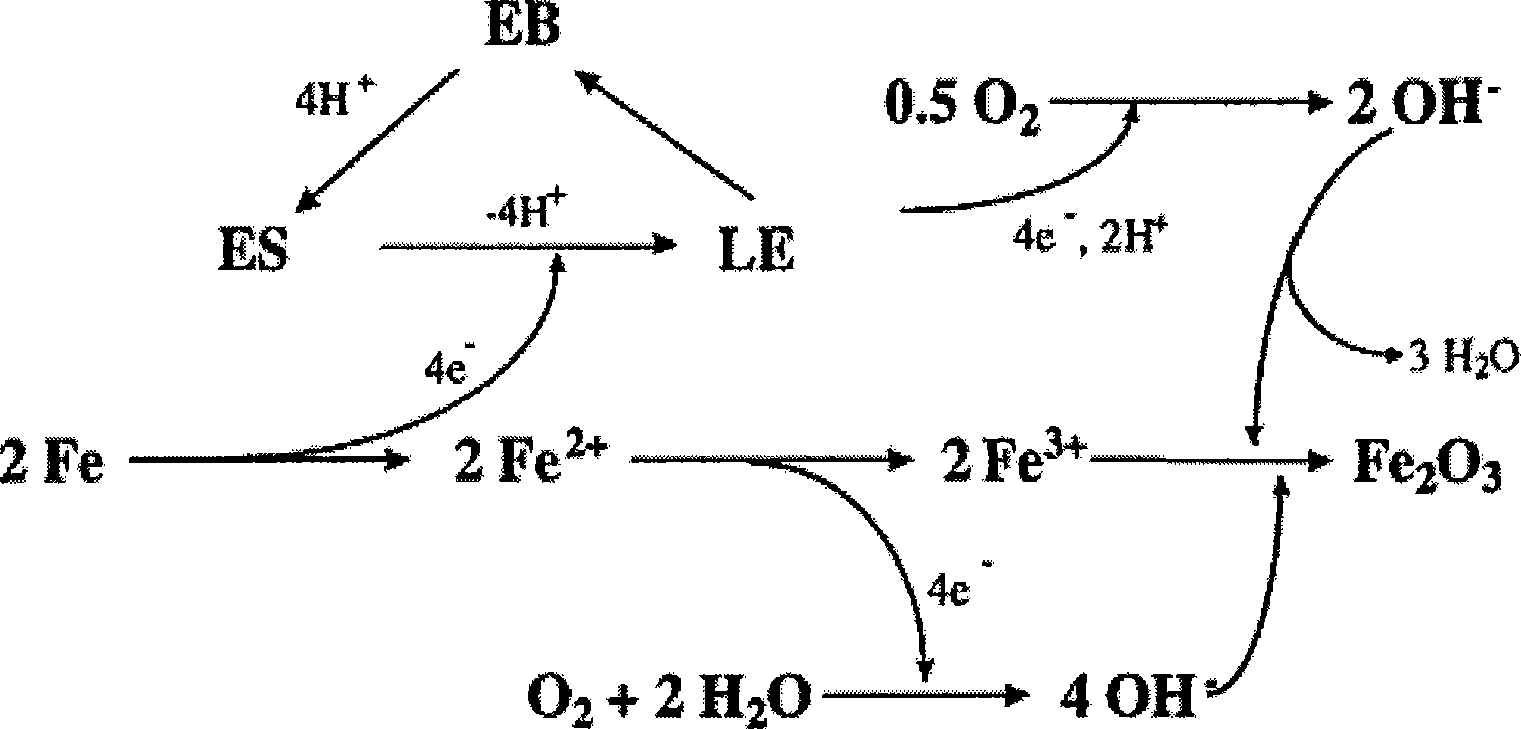

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

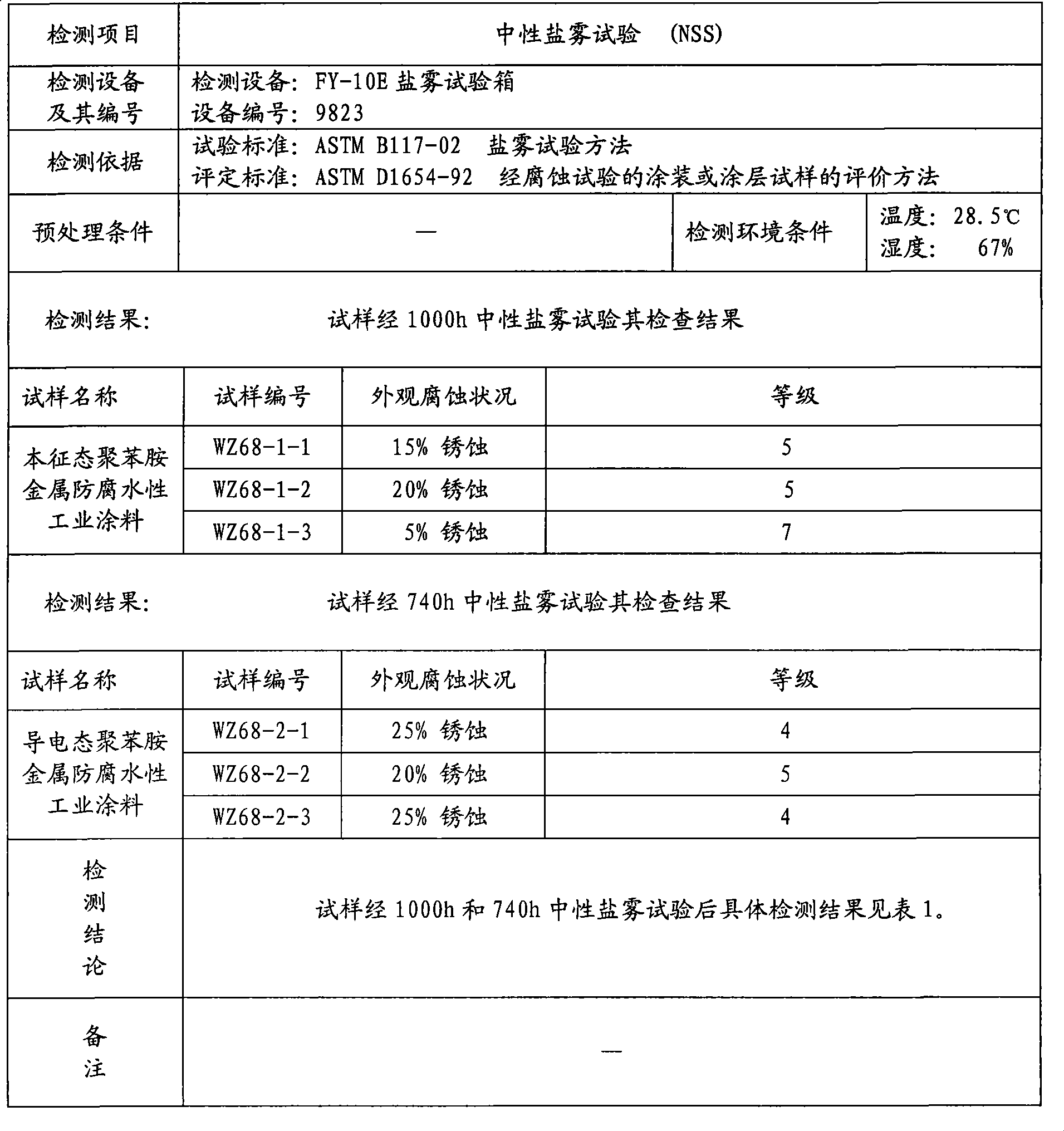

[0036] Embodiment 1 is to manufacture a water-based primer, so the salt spray resistance time detected in neutral salt spray is routinely carried out for 1000 hours.

Embodiment 2

[0037] Embodiment 2 is to manufacture water-based topcoat, which is different from the conventional 500-hour salt-spray resistance of solvent-based paint, and its salt-spray resistance test time is 740 hours.

[0038] Embodiment 1: prepare with the weight percent of all components:

[0039] ① Base material components: 500 mesh zinc powder 50%, coating film-forming water-based epoxy resin 14%, intrinsic polyaniline 1.5%, deionized purified water 18.9%, thickener 2%, dispersing anti-sedimentation agent 3% , 2% defoamer, 3% leveling agent.

[0040] ② Curing agent component: amine-based curing agent 5.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com