Method for extracting high-purity humic acid from low-rank coal

A humic acid, high-purity technology, applied in organic chemistry and other directions, can solve the problems of high processing cost, complex process operation, long process, etc., and achieve the effect of low impurity element content, simple process operation, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

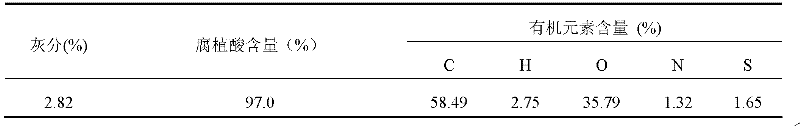

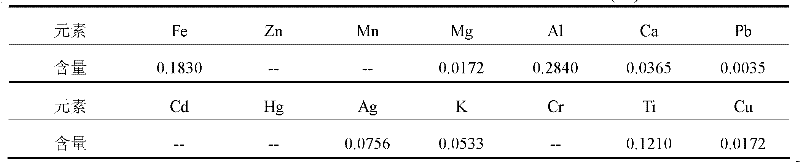

[0030] The air-dried lignite (humic acid content 38%) is crushed and ground to a particle size of not more than 1.0mm in advance, and then the ground coal sample is mixed with 0.15mol / L sodium pyrophosphate solution (the mass ratio of coal sample to sodium pyrophosphate solution 1:8), heated in a water bath at 95°C for 1.0 h, nitrogen gas was introduced and stirred during the heating process; after the extraction process was completed, the mixed solution was poured out and centrifuged at a speed of 3000 r / min, and the centrifugation time was 30 min. The supernatant and precipitate were collected separately. Repeat the above water bath stirring extraction and centrifugation process for the precipitate once. Combine the supernatant obtained twice, add 6mol / L HCl to it to adjust the pH to 2.0, after standing still, use a siphon to absorb most of the supernatant, discard it, and centrifuge again at a speed of 3000r / min, and the centrifugation time is 30min , to collect the precip...

Embodiment 2

[0032]The mixture of air-dried lignite and weathered coal (humic acid content 35%) is crushed and ground to a particle size not greater than 1.0mm, and then the ground coal sample is mixed with 0.05mol / L sodium hydroxide solution (coal sample and hydroxide After the mass ratio of the sodium solution is 1:9), heat in a water bath at a temperature of 80°C for 1.5h, feed nitrogen and stir during the heating process; after the extraction process is completed, pour out the mixed solution and centrifuge at a speed of 5000r / min, The separation time was 20minmin, and the supernatant liquid and precipitate were collected respectively. Repeat the above water bath stirring extraction and centrifugation process for the precipitate once. Combine the supernatant obtained twice, add 6mol / L HCl to it to adjust the pH to 2.0, after standing still, use a siphon to absorb most of the supernatant, discard it, and centrifuge again at a speed of 5000r / min, and the centrifugation time is 20min , to...

Embodiment 3

[0034] The mixture of air-dried lignite and peat (44.7% humic acid content) was crushed and ground to a particle size not greater than 1.0mm, and then the ground coal sample was mixed with 0.25mol / L sodium carbonate solution (the ratio of coal sample to sodium carbonate solution After the mass ratio is 1:10), heat in a water bath at a temperature of 50°C for 2.0h, feed nitrogen gas and stir during the heating process; after the extraction process is completed, pour out the mixed solution for centrifugation at a speed of 10000r / min, and the centrifugation time is 10minmin, collect the supernatant and precipitate respectively. Repeat the above water bath stirring extraction and centrifugation process for the precipitate once. Combine the supernatant obtained twice, add 6mol / L HCl to it to adjust the pH to 2.0, and after standing still, use a siphon to absorb most of the supernatant, discard it, and centrifuge again at a speed of 10000r / min, and the centrifugation time is 10min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com