Anti-pricking and anti-busting scientific and technical safety tire and machining method thereof

A technology for safety tires and processing methods, applied in special tires, tire parts, chemical instruments and methods, etc., can solve problems such as small temperature range, inability to large-scale industrialization, affecting vehicle dynamic balance, etc. The effect of forming the adhesive layer, preventing air oxidation pollution, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

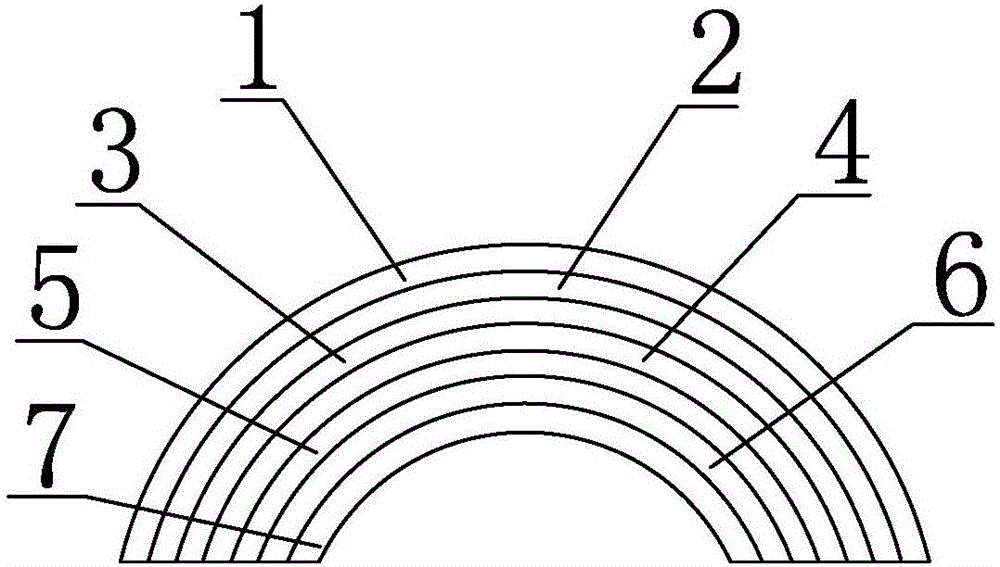

[0025] Such as figure 1 As shown, a safety tire with anti-puncture and anti-explosion technology is composed of tread rubber layer 1, buffer layer 2, steel belt layer 3, cord fabric layer 4, airtight layer 5 and polymer composite from outside to inside. The memory rubber layer 6, the polymer synthetic memory rubber layer 6 has a thickness of 1.5-20mm.

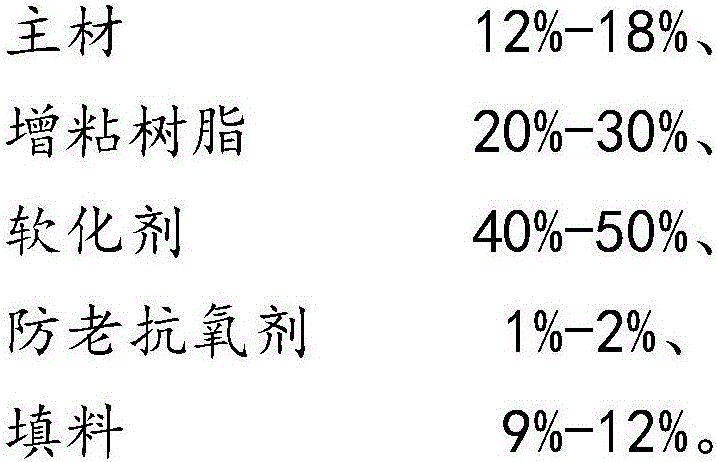

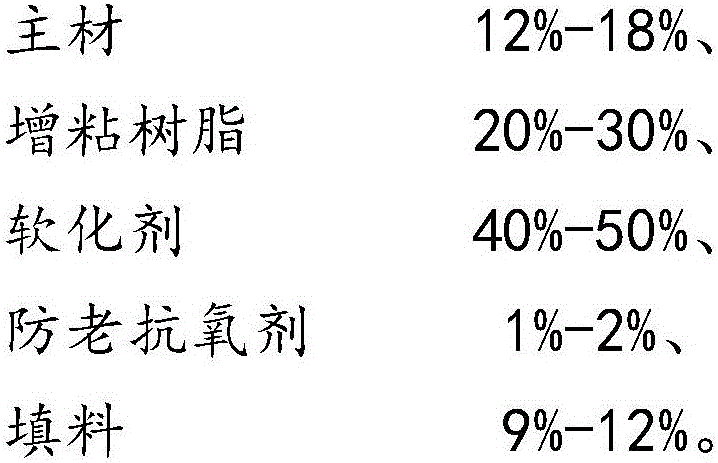

[0026] Described macromolecule synthetic memory glue material layer 6 is made of the raw material of following percentage:

[0027]

[0028] The main material is at least two of EVA ethylene-vinyl acetate copolymer, thermoplastic elastomer, butyl rubber, chlorinated butyl rubber, brominated butyl rubber, polybutene, and APAO amorphous polyolefin.

[0029] The tackifying resin is at least one of C5 / C9 petroleum resin, hydrogenated C5 petroleum resin, rosin pentaerythritol ester, rosin gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com