Method for intersection angle high-speed railway underpassing low-clearance girder erection

A technology of acute angle crossing and construction method, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., and can solve the problems of beam erection construction and the inability to use bridge erection machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

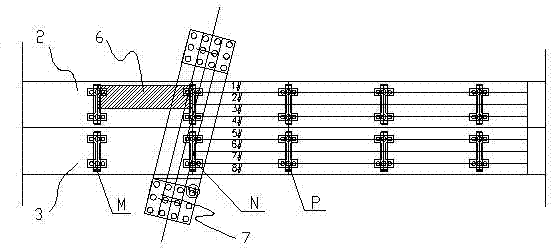

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

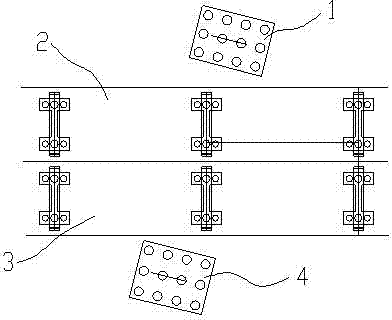

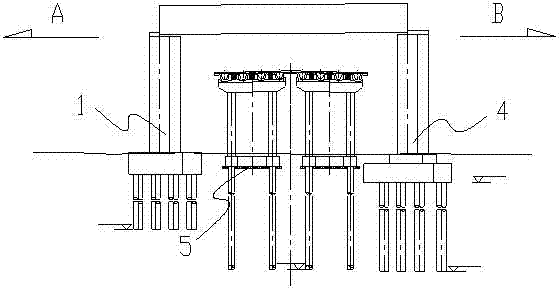

[0033] Such as figure 1 , figure 2 As shown, the present embodiment is a construction method for erecting girders with high-speed railways crossing at an acute angle and passing under the high-speed rail. Take the following specific site conditions as an example: a new expressway Jiangbei connection line project, the highway runs north-south, and crosses a river from south to north. , across the passenger-dedicated line railway, and across the electrified railway, the whole line is a viaduct structure with a total length of 1km, and the left and right sides of the bridge deck are separated. It is located between the existing highway across Pier 1 and the existing highway across Pier 4. Sheet 2 and right sheet 3 of the high-speed railway, the width of the whole bridge is 25m. The upper structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com