Steel trussed beam and flexible arch bridge construction method with vault pushing

A construction method and technology of steel truss girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large span, high cost, and difficult operation of steel bridges, and achieve centralized assembly operation sites and roof lifting. The effect of small displacement value and reduced operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

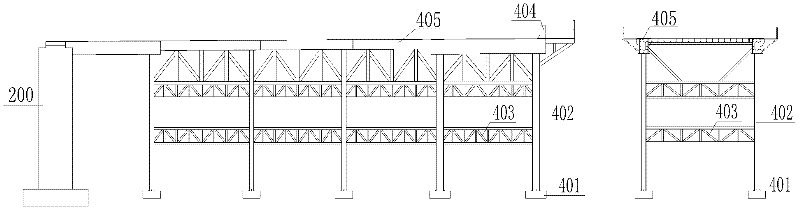

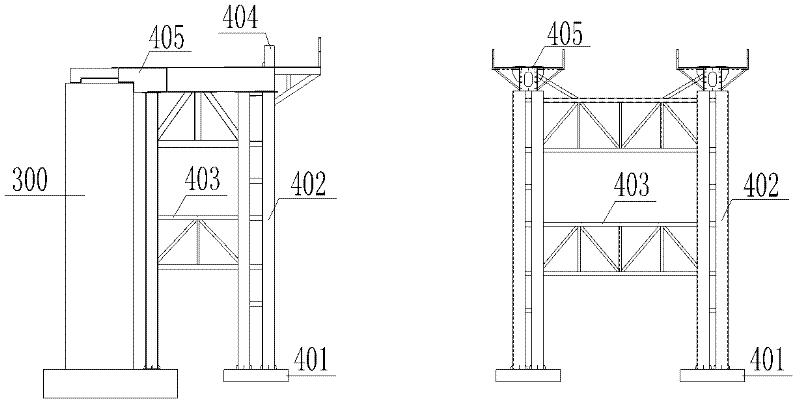

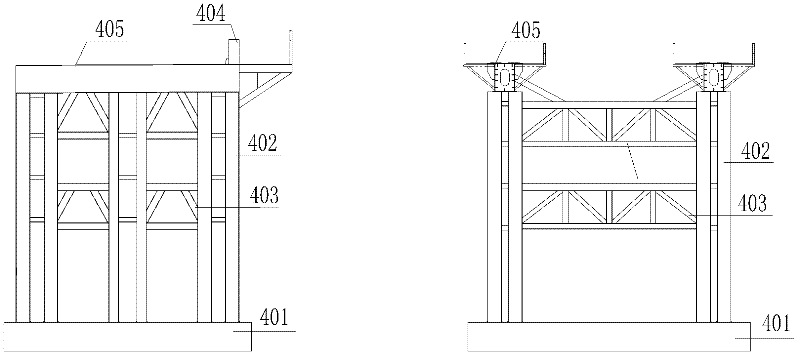

[0047] Referring to the accompanying drawings, according to the calculation and analysis of the working condition of the vaulted roof, it is necessary to set up temporary supports for steel bridge erection and jacking construction, and to set up multi-span assembly supports 410 at the side-span main pier 200 assembly yard, the middle-span main pier 300 and the other side A bracket 420 next to the pier is set at the main pier 200, and a temporary pier bracket 430 is set in the middle of the span.

[0048] The structure of the assembly bracket 410 is as follows figure 1 As shown, the structure of the bracket 420 next to the pier is as follows figure 2 As shown, the structure of the temporary pier support 430 in the middle span of the main span is as follows: image 3 shown. The lower part of the steel pipe column 402 is a pile foundation cap 401, and the columns are connected by a pipe truss 403. A steel box structure slideway beam 405 is installed on the top surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com