Concrete construction quality intelligent visualized monitoring system based on cloud technology platform

A technology of construction quality and monitoring system, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problem that it is difficult to effectively monitor and real-time concrete quality, the collected data cannot be automatically stored and processed, and the construction quality is affected. Timely feedback and other issues to achieve the effect of reducing the workload of feedback and repairing, avoiding irreparable defects, and avoiding poor communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

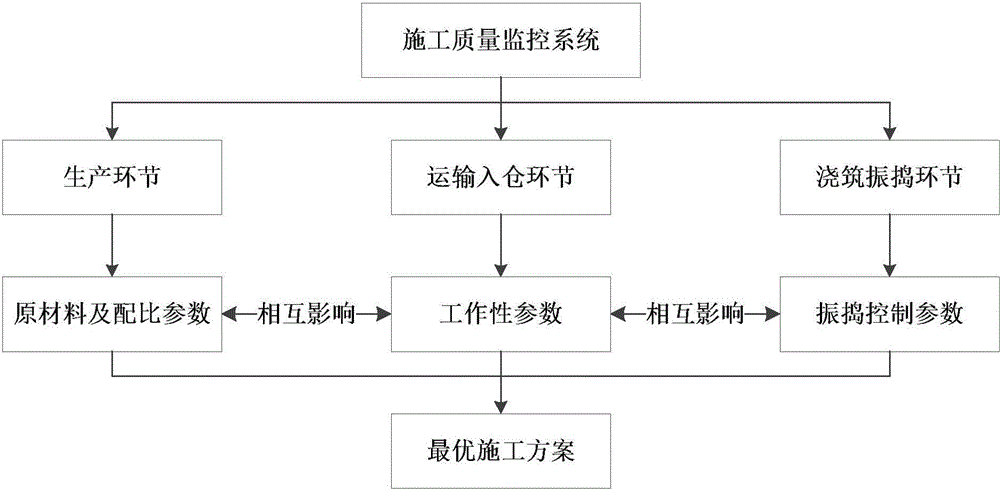

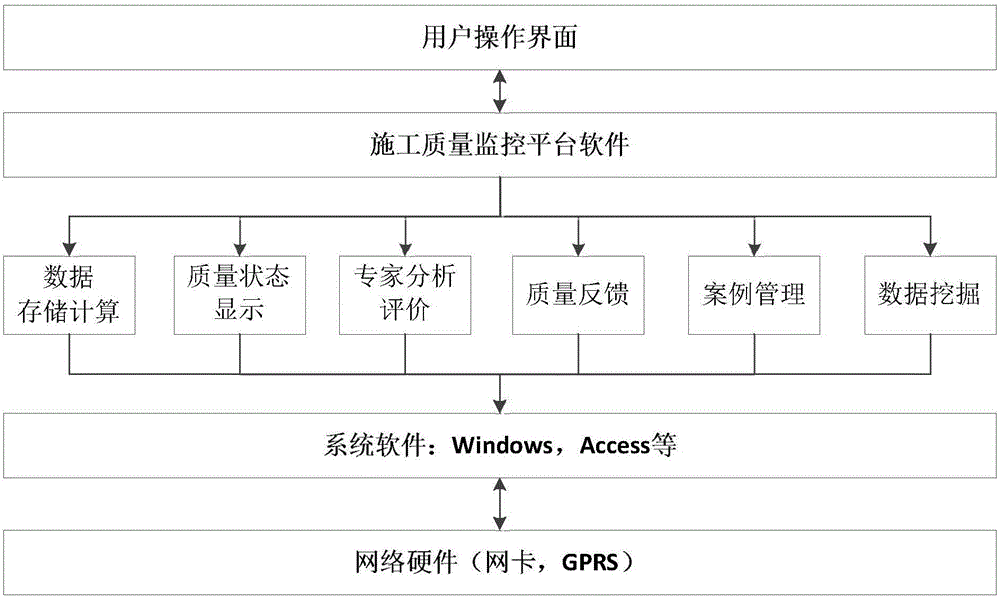

[0033] The concrete construction quality intelligent visual monitoring system based on the cloud technology platform of this embodiment is as follows: figure 1 As shown, the quality information parameters of the three links of concrete construction production, transportation, and pouring are obtained through corresponding equipment, and are wirelessly sent to the quality real-time monitoring platform in the cloud server. After cloud storage, calculation, and display, the construction quality status of each process link is analyzed. , and timely transmit feedback adjustment plan information to relevant operators.

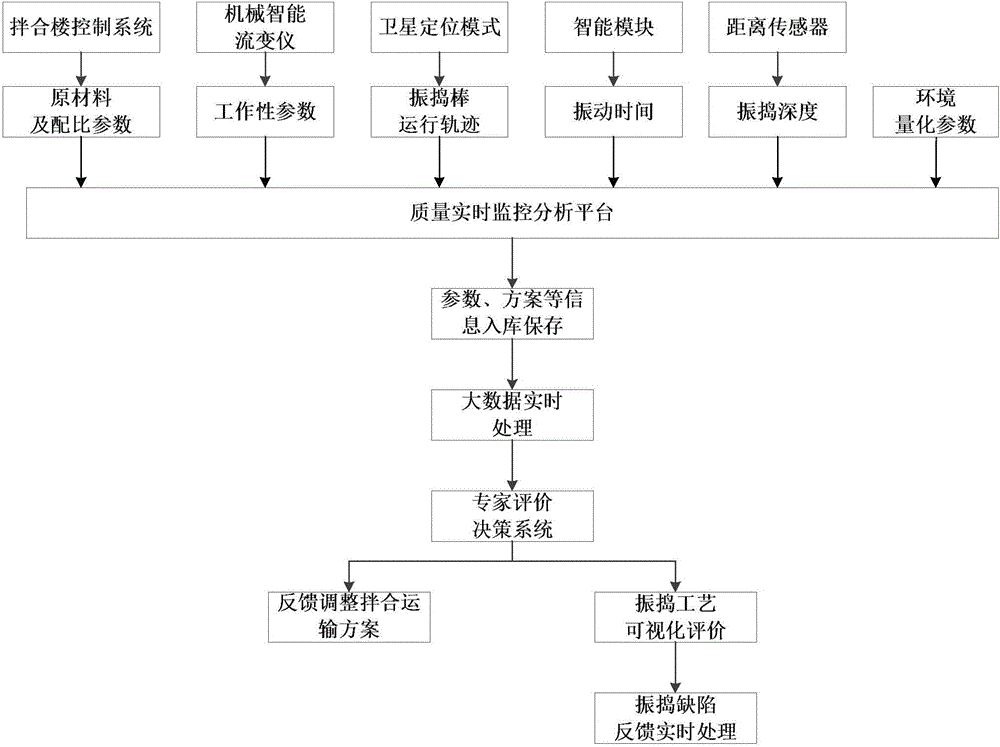

[0034] Its monitoring process is as follows figure 2 as shown,

[0035] First, collect operation information, use the host computer in the mixing control room to automatically collect concrete raw materials and proportion parameters in real time, use the mechanical intelligent online rheometer to collect workability data, and use the satellite positioning module an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com