Method for constructing from inclined shaft to main tunnel in weak surrounding rock

A technology with weak surrounding rocks and construction methods, which is applied in shaft lining, shaft equipment, earthwork drilling and mining, etc., can solve the construction problems of inclined shafts and reduce safety risks, and achieve remarkable results and reduce safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

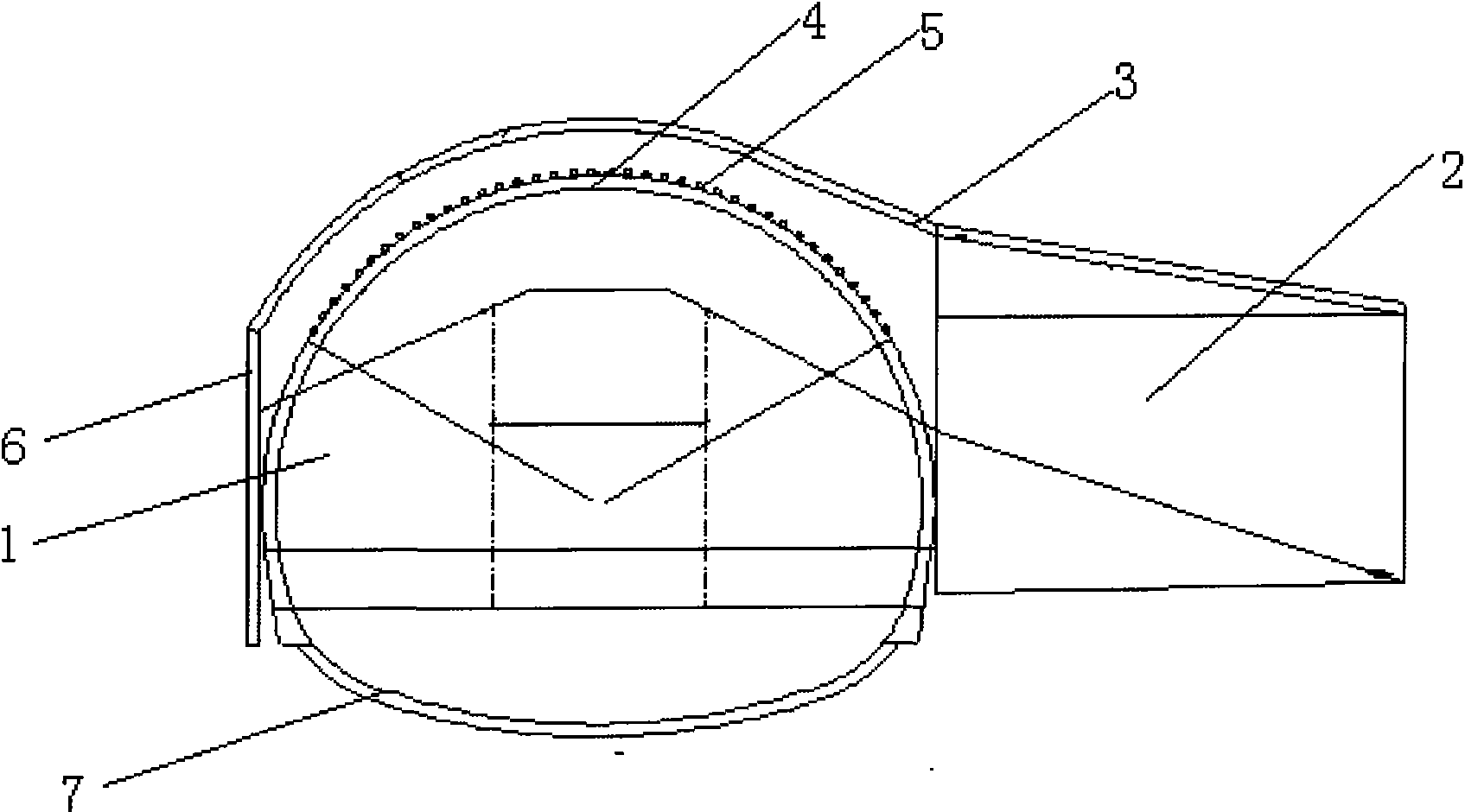

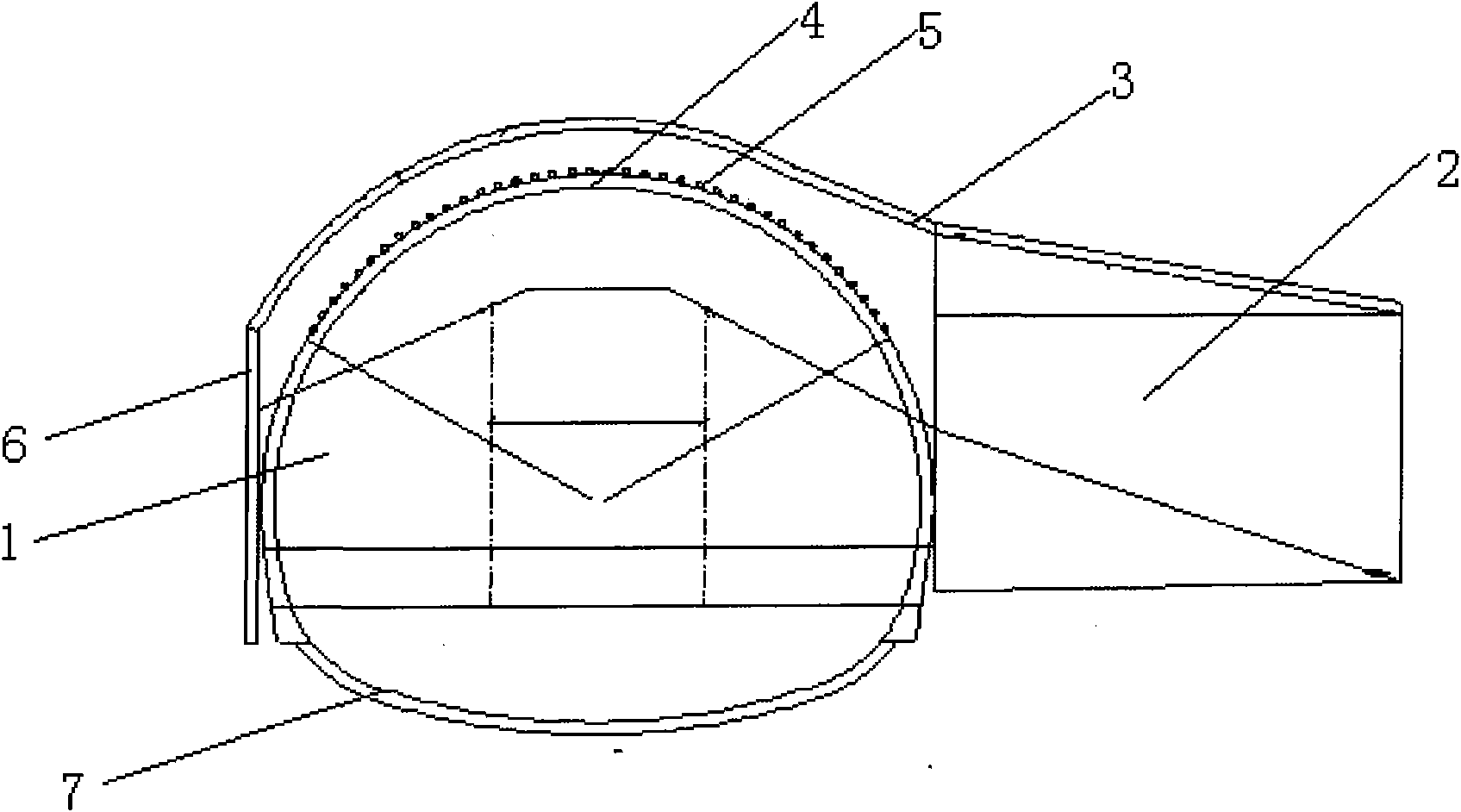

[0013] Referring to the accompanying drawings, the construction method of the inclined shaft with weak surrounding rocks to the normal tunnel is carried out according to the following construction steps:

[0014] 1) When excavating the main tunnel in the area with weak surrounding rock geological conditions, start digging the inclined shaft 2 with a slope of 20% at a distance of 10m from the construction side of the main tunnel 1. The contour line of the main tunnel section is 2 meters high and the arc-shaped roadway is expanded, and the excavation width remains unchanged. The small arch support frame 3 is used for initial support in the inclined shaft and the roadway, and the small arch support frame adopts I20b steel arch frame Support, spacing 0.6m / pile;

[0015] 2) Install the large arch support frame 4 on the section of the front hole 1, cut off the side wall legs of the small arch support frame 1, and connect the two legs of the small arch support frame to the large arch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com