Construction method of structure conversion layer concrete girder steel bracket formwork support

A technology of structural conversion layer and formwork support, which is applied to the connection parts of formwork/formwork/work frame, girders, truss structures, etc., which can solve the problems that the design bearing capacity of the lower floor cannot bear and the safety of the frame cannot be guaranteed. Achieve the effect of reasonable force, convenient construction and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

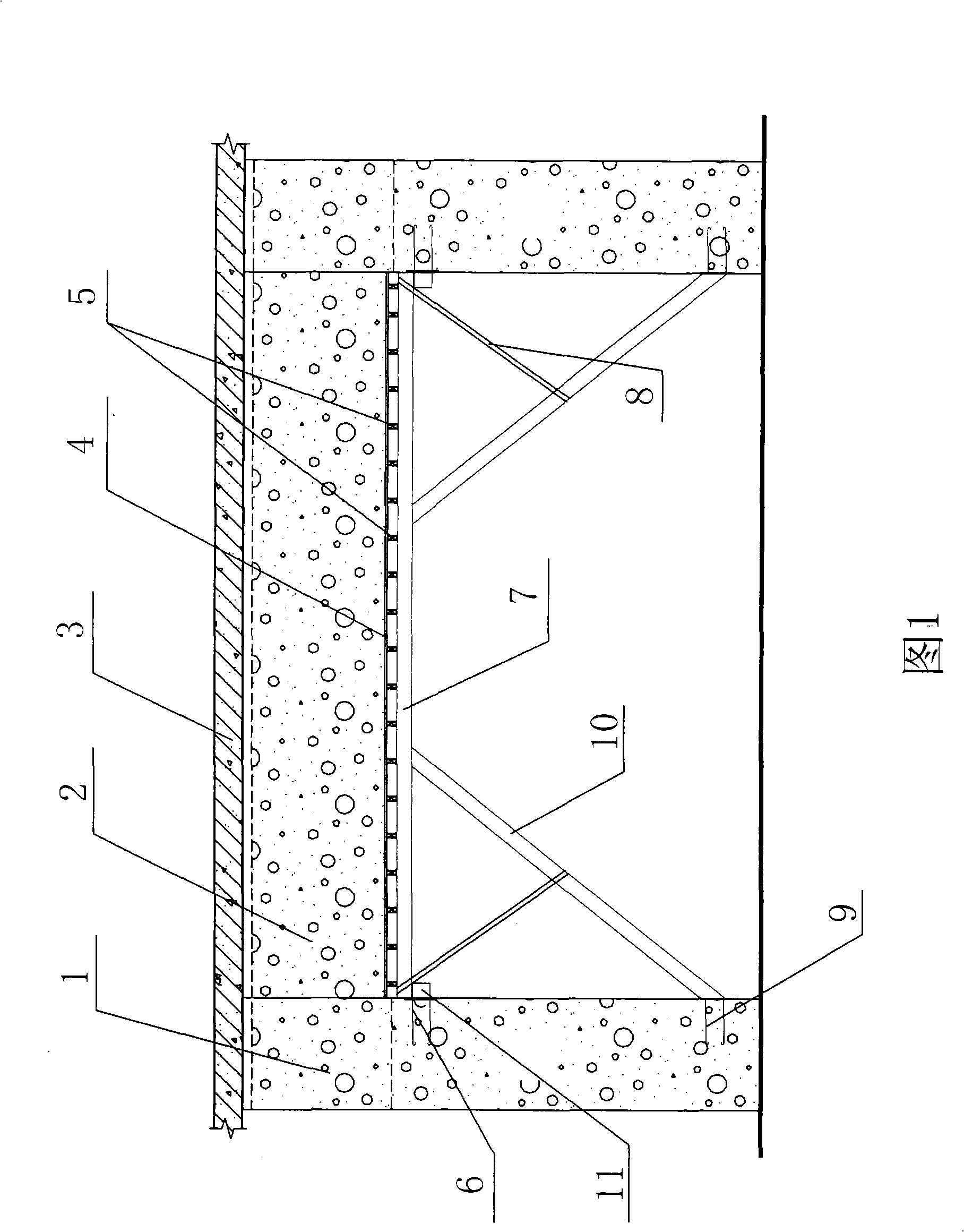

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] First, the embedded parts of the joist support bracket are buried. After the steel bars of the transfer layer column 1 are bound, the embedded parts of the joist support bracket are embedded in the transfer layer column 1 under the transfer layer beam 2, including the upper embedded part 6. and the lower embedded part 9, the upper embedded part 6 in this embodiment is welded by 2Φ18 U-shaped I-grade steel bars and -200 × 200 × 16 steel plates, and is buried at 380-400 mm below the transfer floor beam 2; the lower pre-embedded Embedded parts 9 are welded by 2Φ18 U-shaped I-grade steel bars and -350×200×16 steel plates, and are buried at the height of 300-500 mm at the lower foot of column 1 of the transfer layer. The welding of upper embedded parts 6 and lower embedded parts 9 adopts Double-sided welding, welding seam height 10mm, welding rod adopts E43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com