Vertical shaft type impact crusher with powder and dust removal function and powder and dust removal method

An impact crusher, vertical shaft technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effect of reducing output, avoiding mutual interference, and avoiding repeated crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to better explain the content of the present invention, the technical solutions of the present invention will be described below in conjunction with the drawings and through specific implementation methods.

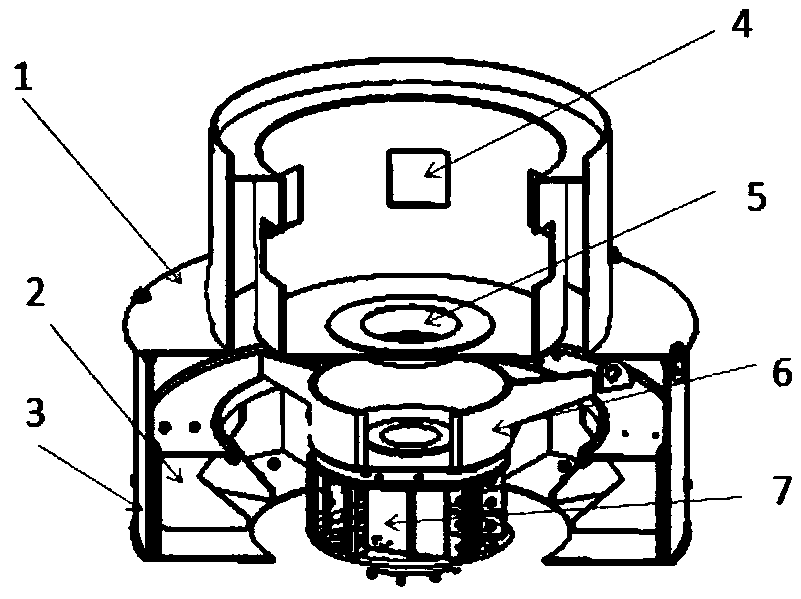

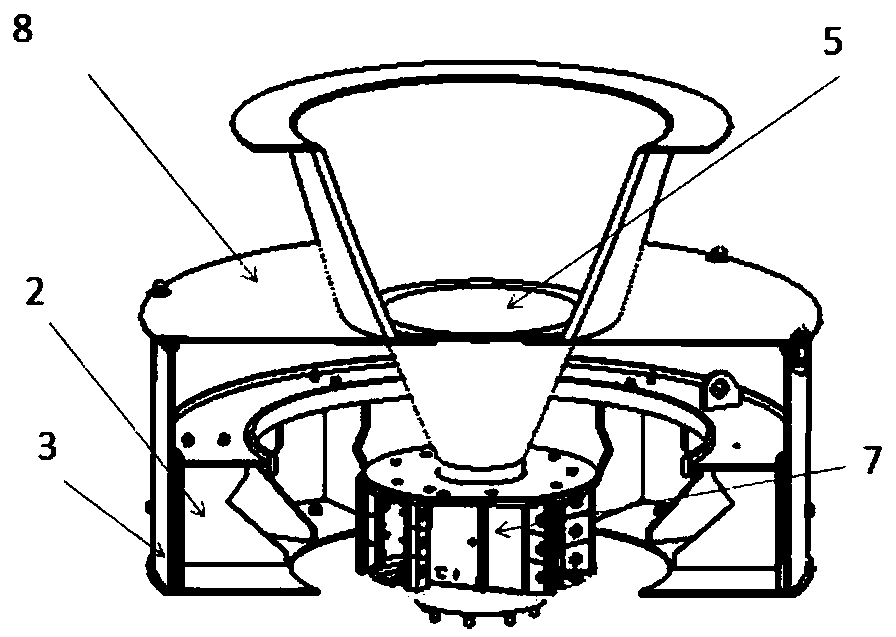

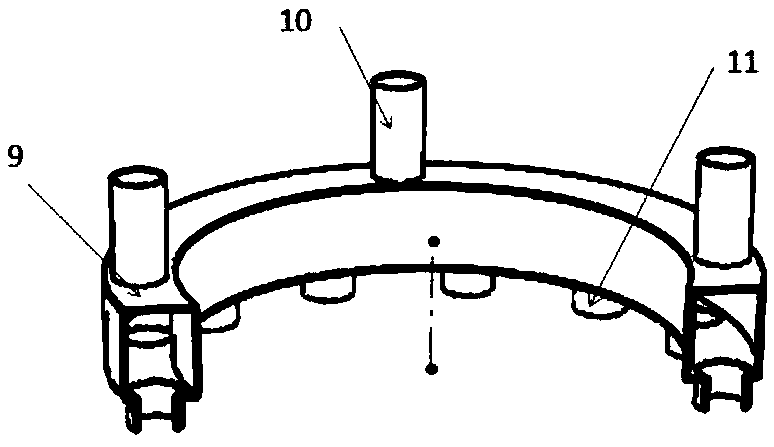

[0064] figure 1 It is a schematic diagram of a conventional stone-lined overflow vertical shaft impact crusher. The stone material mainly enters the sub-hopper 6 from the central material inlet 5 of the overflow flow hopper 1 and then enters the rotor 7, and is thrown from the passage of the rotor 7 to the middle stone-lined chamber 2 of the middle body 3, and the initial stone will be in the middle stone-lined chamber 2 Accumulation, accumulation to the repose corner of the stone, the stone lining is formed. Subsequent stones will hit the stone lining, which protects the stone lining cavity 2. The impact of the stones and the stone lining will break the stones, and produce a large amount of sand and stone powder, and the sand will fall from the space bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com