Closed-loop control crushing system and closed-loop control method for sintered fuel

A closed-loop control and crushing system technology, applied in the field of metallurgical technology, can solve the problems of low crushing efficiency, production quality, cost impact, uncontrolled fuel particle size, etc., achieve strong stability, ensure the quality of sintered fuel, and reduce crushing The effect of equipment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

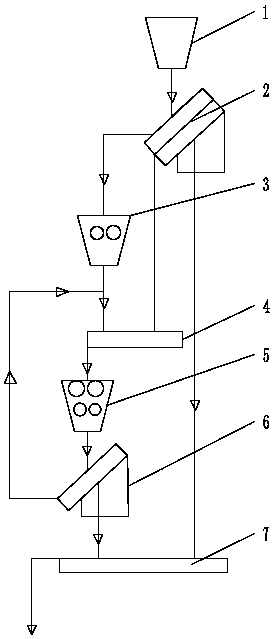

[0021] Such as figure 1 As shown, the closed-loop control crushing system of sintered fuel in this embodiment includes a double-layer vibrating screen 2 with an aperture of the upper sieve plate larger than the aperture of the lower sieve plate arranged under the fuel bin 1, and the upper layer of the double-layer vibrating screen comes out of the sieve. The feed port is connected to the roller crusher 3, and the discharge port of the roller crusher and the middle layer discharge port of the double-layer vibrating screen are all connected to the four-roll crusher 5 through the first belt conveyor 4. The discharge port of the four-roller crusher is connected to the single-layer vibrating scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com