Laser drill bit with negative pressure suction function

A laser and negative pressure technology, used in drill bits, thermal drilling, drilling equipment, etc., can solve the problem that broken cuttings cannot be carried away in time, and achieve the effect of avoiding repeated crushing, improving rock breaking efficiency and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

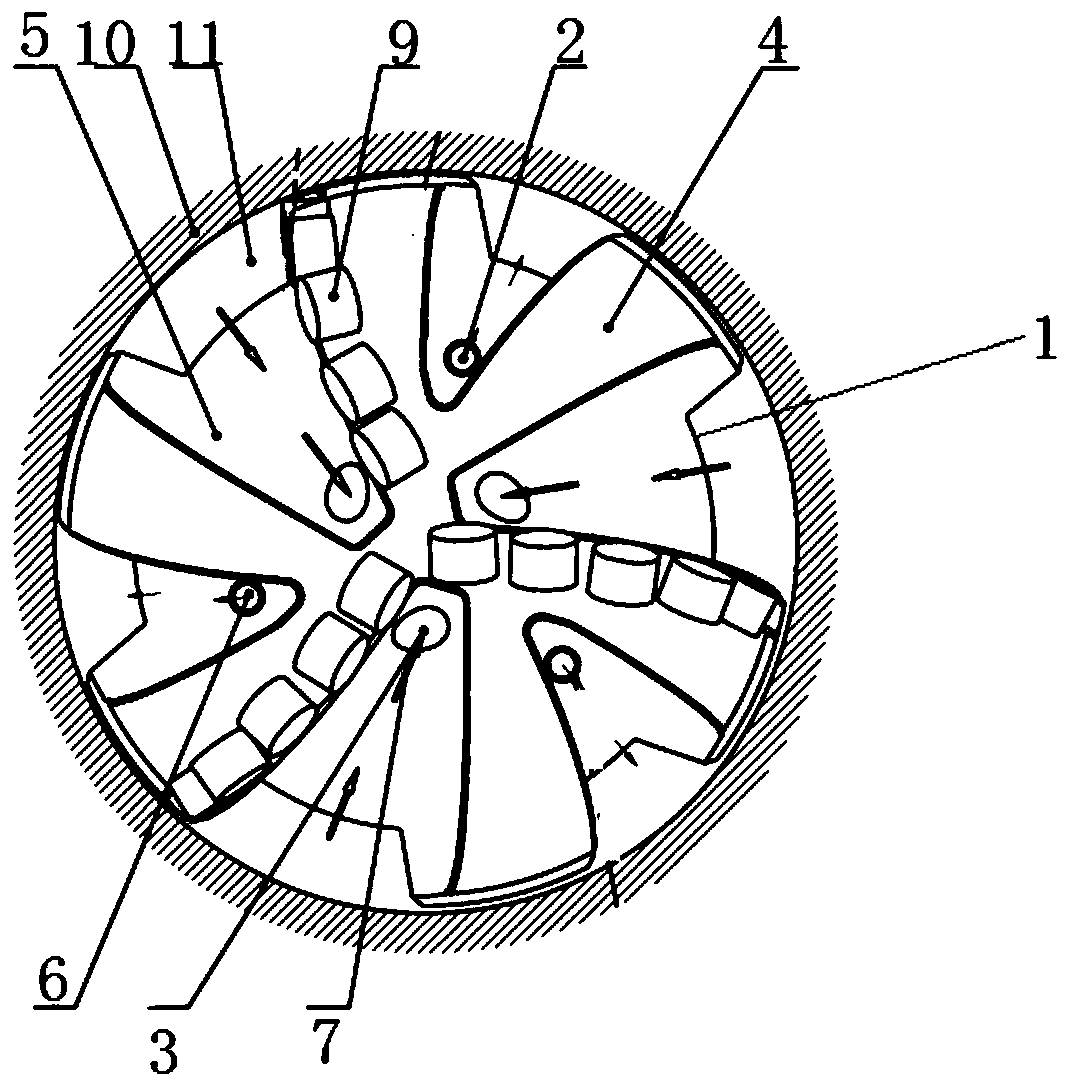

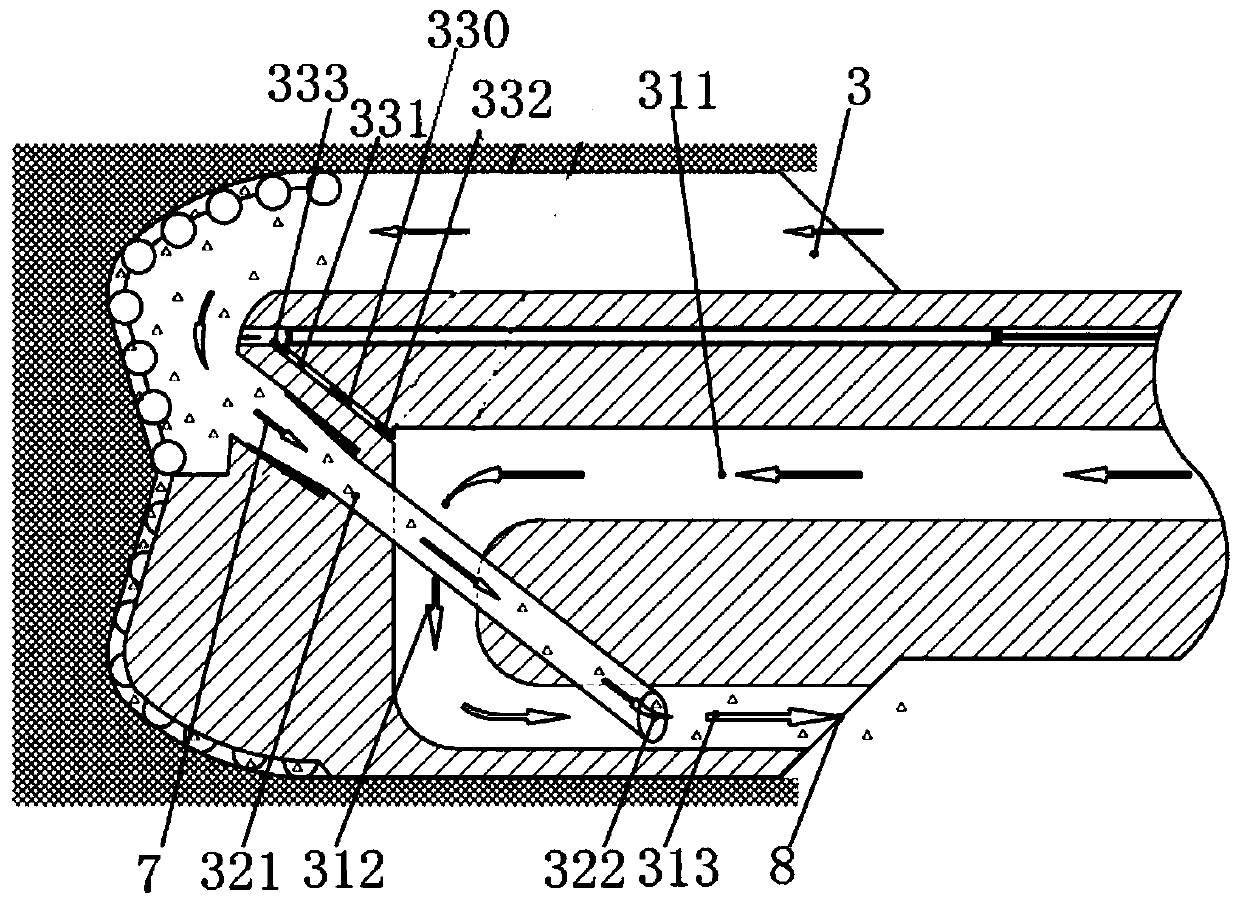

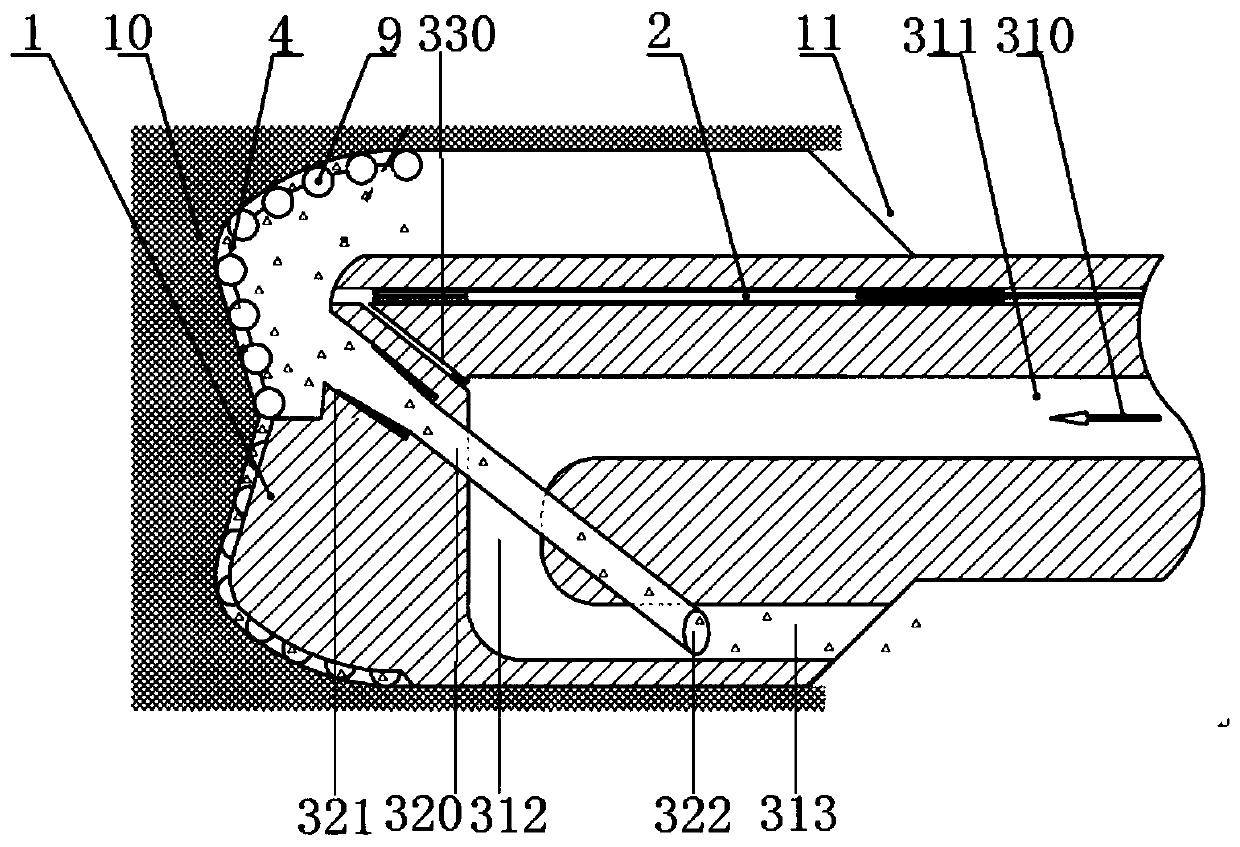

[0025] A kind of laser drill bit with negative pressure suction function of the present invention, such as figure 1 As shown, a drill body 1 is included, and a laser system 2 and a fluid circulation system 3 are arranged in the drill body 1 . A plurality of blades 4 are arranged on the drill body 1 , and chip removal grooves 5 are formed between two adjacent blades 4 . The blades 4 protrude from the bit body 1 so that an annular space 10 is formed between the bit body 1 and the bottom hole rock 9 . During work, the chip flute 5 and the annular space 10 are filled with broken rock cuttings. Such as figure 2 and image 3 As shown, a laser outlet 6 connected to the laser system 2, a water hole 7 and a water outlet 8 connected to the fluid circulation system 3 are provided on the chip removal groove 5, and the laser outlet 6 and the water ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com