Chemical raw material crushing device

A technology for pulverizing device and chemical raw materials, applied in chemical instruments and methods, solid separation, sieving, etc., can solve the problems of crushing dead angle of the pulverizing device, affecting the processing quality of the pulverizing device, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

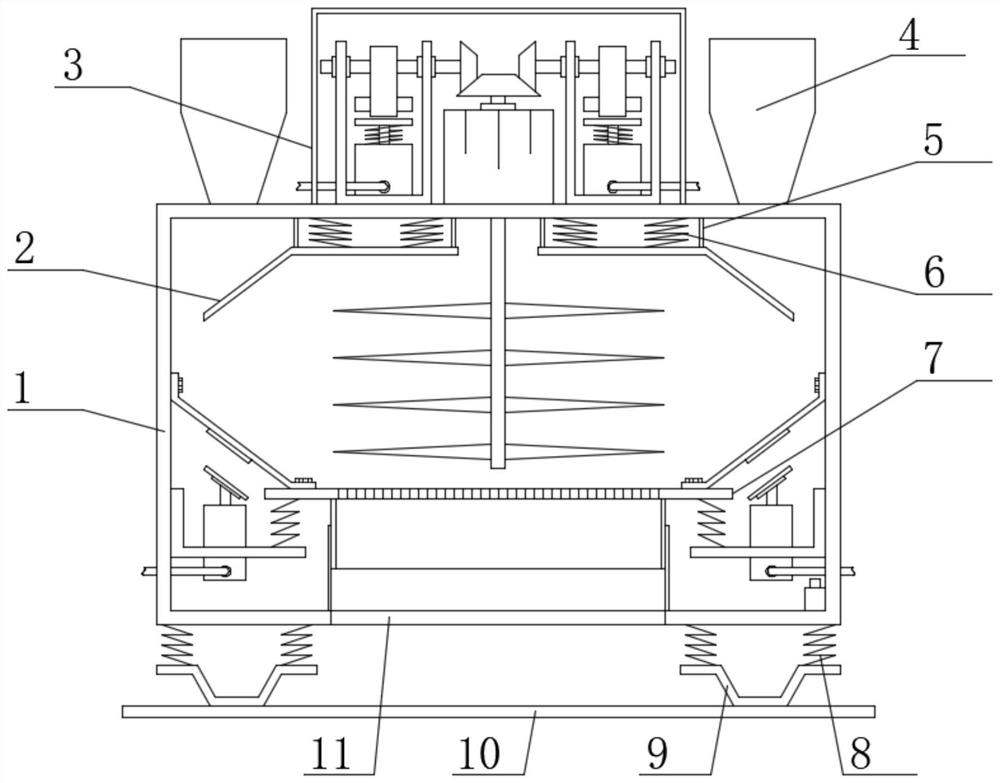

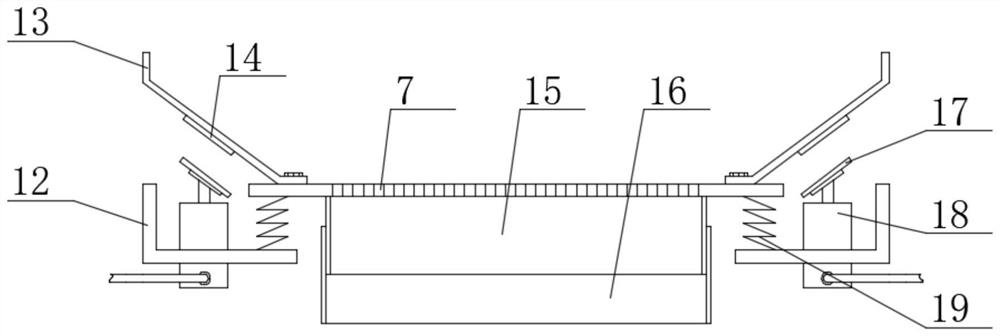

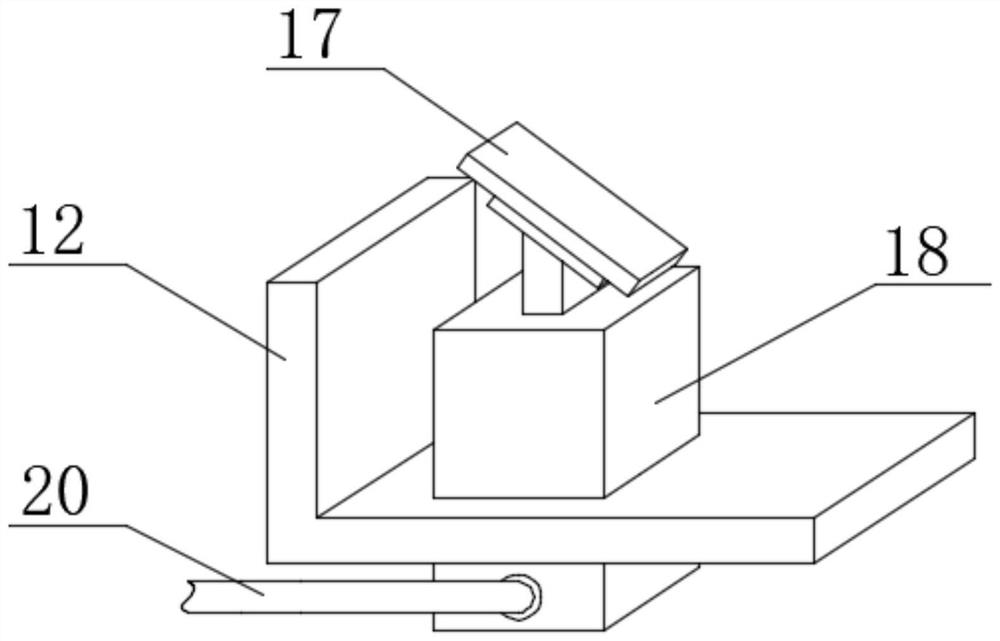

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: a chemical raw material crushing device, comprising a crushing box 1, the two ends of the upper surface of the crushing box 1 are fixedly connected with a lower hopper 4, and the middle part of the lower surface of the crushing box 1 is provided with a discharge through hole 11 , the bottom of the crushing box 1 is provided with a support base plate 10, the two ends of the upper surface of the support base plate 10 are fixedly connected with the limit support plate 9, and the top of the limit support plate 9 is fixedly connected with the second limit spring corresponding to the crush box 1 8. A metal screening plate 7 is arranged inside the crushing box 1, and the lower surface of the metal screening plate 7 is fixedly connected with a first flow guide tube 15 by welding, and the bottom end of the first flow guide tube 15 is slidingly connected with a crushing plate. The second guide tube 16 f...

Embodiment 2

[0032] On the basis of Embodiment 1, in order to improve the crushing effect of the crushing device on the raw material, in this embodiment, preferably, the top of the crushing box 1 is provided with a deflector 2 corresponding to the lower hopper 4, and the deflector 2 One end of the upper surface is fixedly connected with the first limit spring 6 corresponding to the crushing box 1. When in use, the raw materials are dispersed through the deflector 2, so as to avoid the falling of the raw materials and improve the crushing effect of the device on the raw materials;

[0033] In order to make the shock effect of the first limit spring 6 better, in this embodiment, preferably, the top of the first limit spring 6 is fixedly connected with the crushing box 1 by welding, and the bottom end of the first limit spring 6 It is fixedly connected with the deflector 2 by welding, and the deflector 2 is vibrated by the setting of the first limit spring 6 during use, so as to improve the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com