Efficient and durable impact crusher

An impact crusher, durable technology, applied in grain processing and other directions, can solve problems such as reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

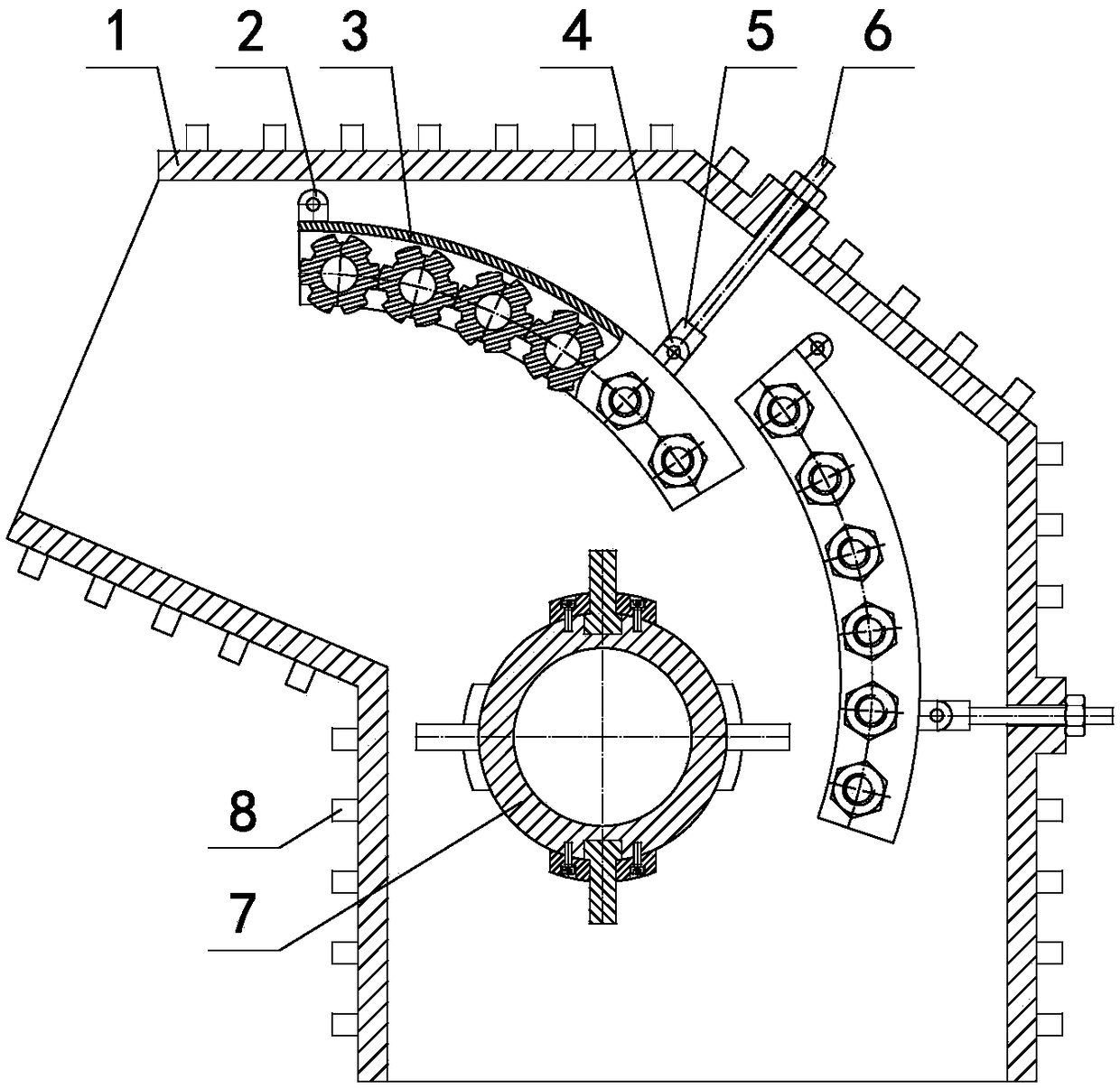

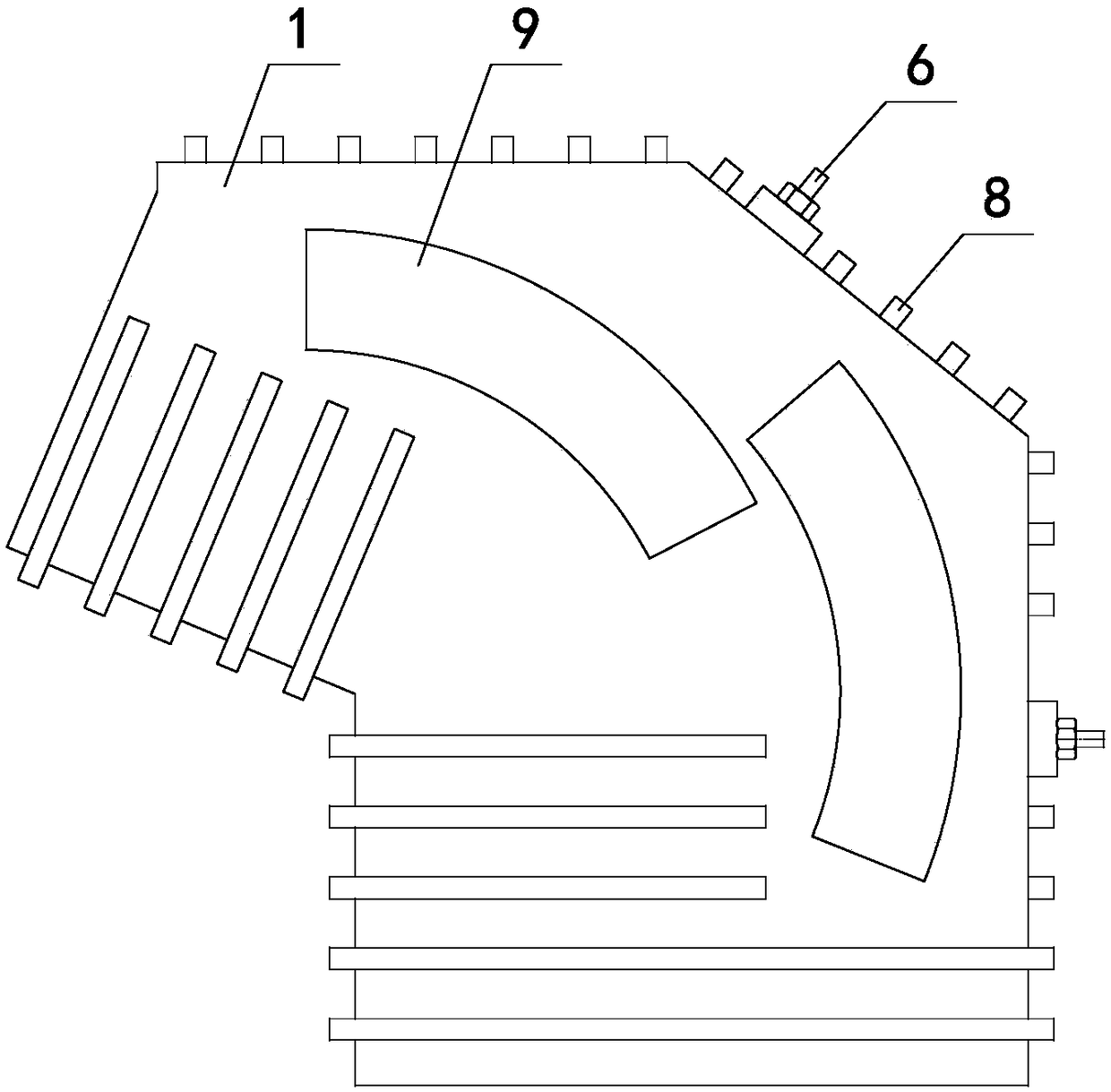

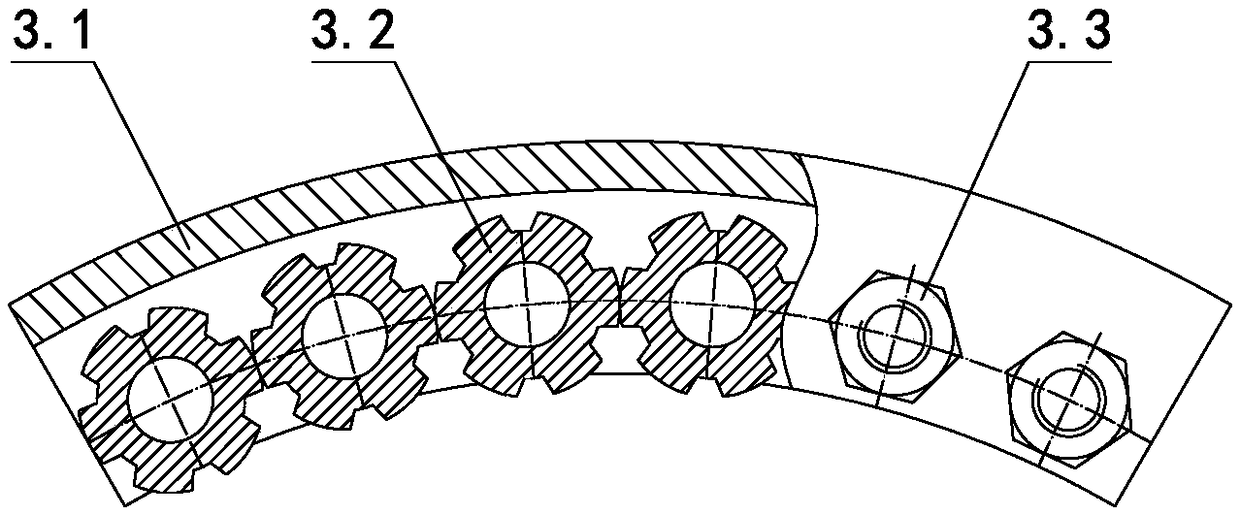

[0025] Such as figure 1 , figure 2 , image 3 , Figure 5 , Image 6 As shown, the high-efficiency and durable impact crusher includes a vertically arranged box body 1, and an impact frame 3 is arranged obliquely in the box, and the impact frame 3 includes an arc-shaped cover plate 3.1. Several counter-attack wheels 3.2, the front and rear ends of the counter-attack wheels 3.2 pass through the arc-shaped cover plate 3.1, the front and rear ends of the counter-attack wheel 3.2 outside the arc-shaped cover plate 3.1 are provided with threads, and lock nuts 3.3 are installed on the threads , the counter wheel 3.2 is installed in the arc cover 3.1 through the lock nut 3.3, the first ear handle 2 is arranged on the back of the arc cover 3.1, and the upper end of the arc cover 3.1 is hinged to the first ear handle through a pin shaft 2, a second ear handle 4 is provided on the back of the arc-shaped cover plate 3.1 on the other side of the first ear handle 2, and a mounting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com