Fluorine-containing silicon monoxide negative electrode material and preparation method and application thereof

A silicon monoxide and negative electrode material technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of capacity retention and coulombic efficiency reduction, capacity fading, cycle performance deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Using an electronic balance, weigh 2g of silicon monoxide (with a particle size of 10-30 μm) and 20 mg of ammonium fluoride (with a particle size of 20-30 μm) and place them in a mortar for grinding for 30 minutes, then mix and continue grinding for 20 minutes. Put the silicon monoxide-ammonium fluoride mixed powder into the tube furnace, close the tube furnace, evacuate the furnace to a vacuum and fill it with argon gas, and then adjust the delivery speed of argon gas to 100-200ppm after going back and forth three times. In an argon atmosphere, the temperature was raised to 300° C. at 2° C. / min, kept for 2 hours, the heating was stopped, and the product was taken out after naturally cooling to room temperature to obtain a fluorine-containing silicon monoxide negative electrode material (F- SiO), and its scanning electron micrographs are shown in figure 1 shown. from figure 1 It can be seen from the figure that the synthesized material maintains the original block str...

Embodiment 2

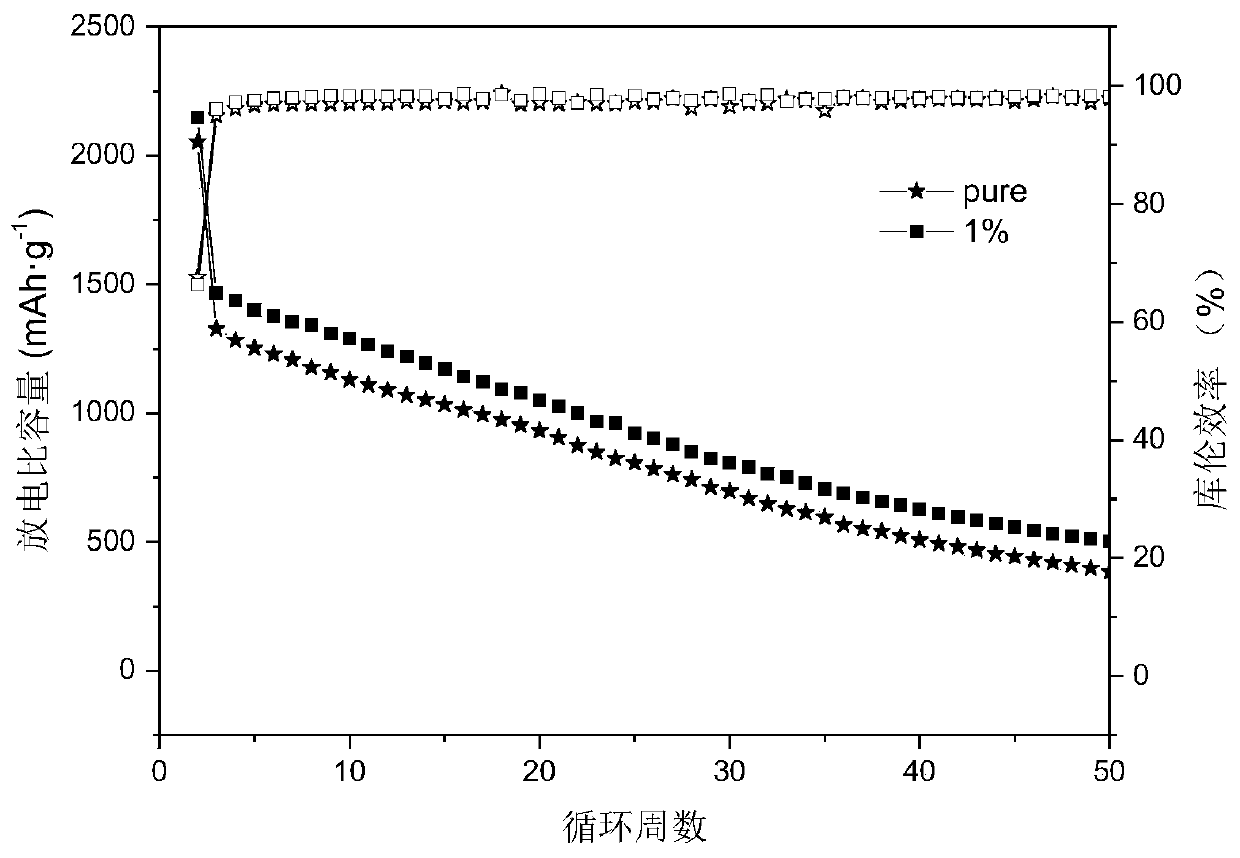

[0051] Using an electronic balance, weigh 2g of silicon monoxide (with a particle size of 10-30 μm) and 60 mg of ammonium fluoride (with a particle size of 20-30 μm) and place them in a mortar for grinding for 30 minutes, then mix and continue grinding for 20 minutes. Put the silicon monoxide-ammonium fluoride mixed powder into the tube furnace, close the tube furnace, evacuate the furnace to a vacuum and fill it with argon gas, and then adjust the delivery speed of argon gas to 100-200ppm after going back and forth three times. In an argon atmosphere, the temperature was raised to 300° C. at 2° C. / min, kept for 2 hours, the heating was stopped, and the product was taken out after naturally cooling to room temperature to obtain a fluorine-containing silicon monoxide negative electrode material (F- SiO).

[0052] Mix 280mg of F-SiO material, 80mg of acetylene black, 2g of 2wt% sodium alginate solution and 3ml of deionized water, stir evenly, adjust the viscosity, and obtain neg...

Embodiment 3

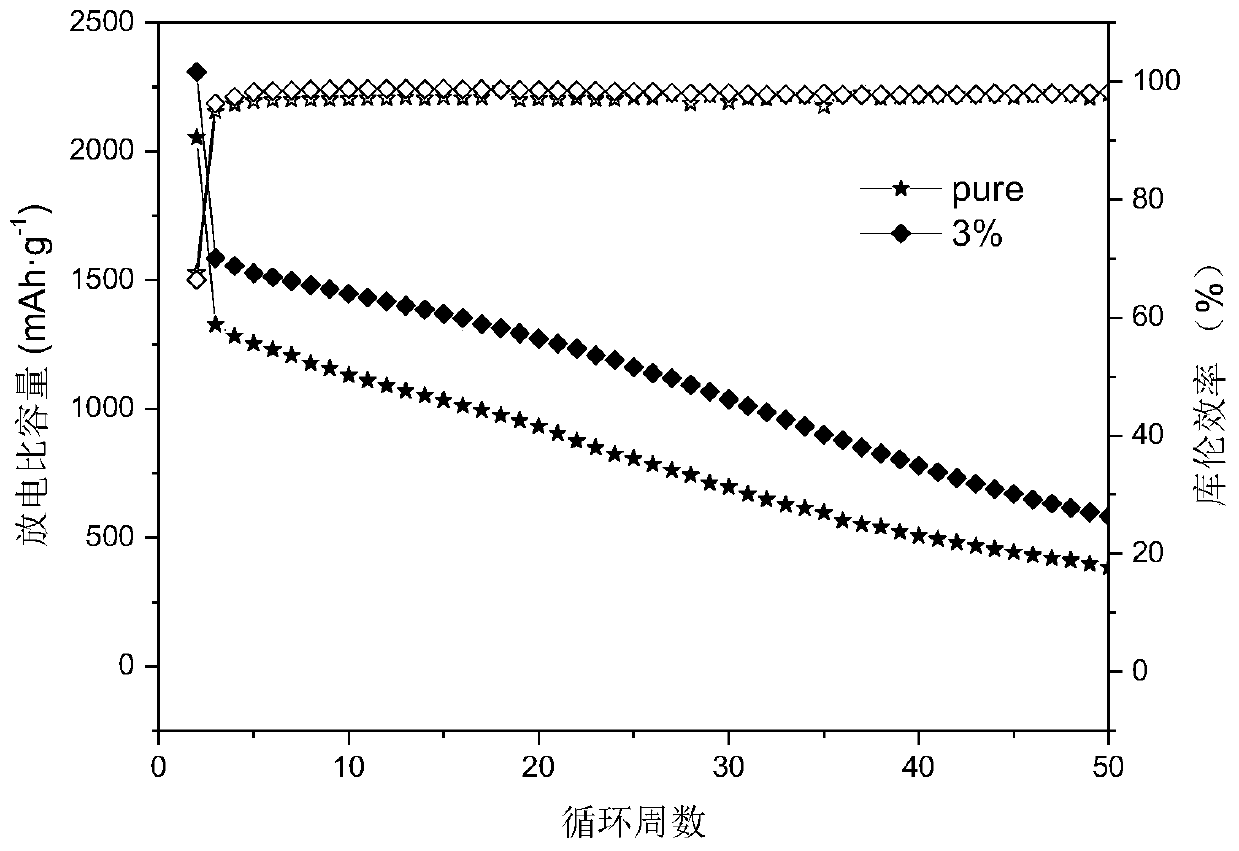

[0055] Using an electronic balance, weigh 2g of silicon monoxide (with a particle size of 10-30 μm) and 100 mg of ammonium fluoride (with a particle size of 20-30 μm) and place them in a mortar for grinding for 30 minutes, then mix and continue grinding for 20 minutes. Put the silicon monoxide-ammonium fluoride mixed powder into the tube furnace, close the tube furnace, evacuate the furnace to a vacuum and fill it with argon gas, and then adjust the delivery speed of argon gas to 100-200ppm after going back and forth three times. In an argon atmosphere, the temperature was raised to 300° C. at 2° C. / min, kept for 2 hours, the heating was stopped, and the product was taken out after naturally cooling to room temperature to obtain a fluorine-containing silicon monoxide negative electrode material (F- SiO).

[0056] Mix 280mg of F-SiO material, 80mg of acetylene black, 2g of 2wt% sodium alginate solution and 3ml of deionized water, stir evenly, adjust the viscosity, and obtain ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com