High-voltage electric pulse crushing pre-weakening and enriching process for metal ores

A high-voltage electric pulse, metal ore technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems of low efficiency and high energy consumption, and achieve low energy consumption, stable and reliable operation, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

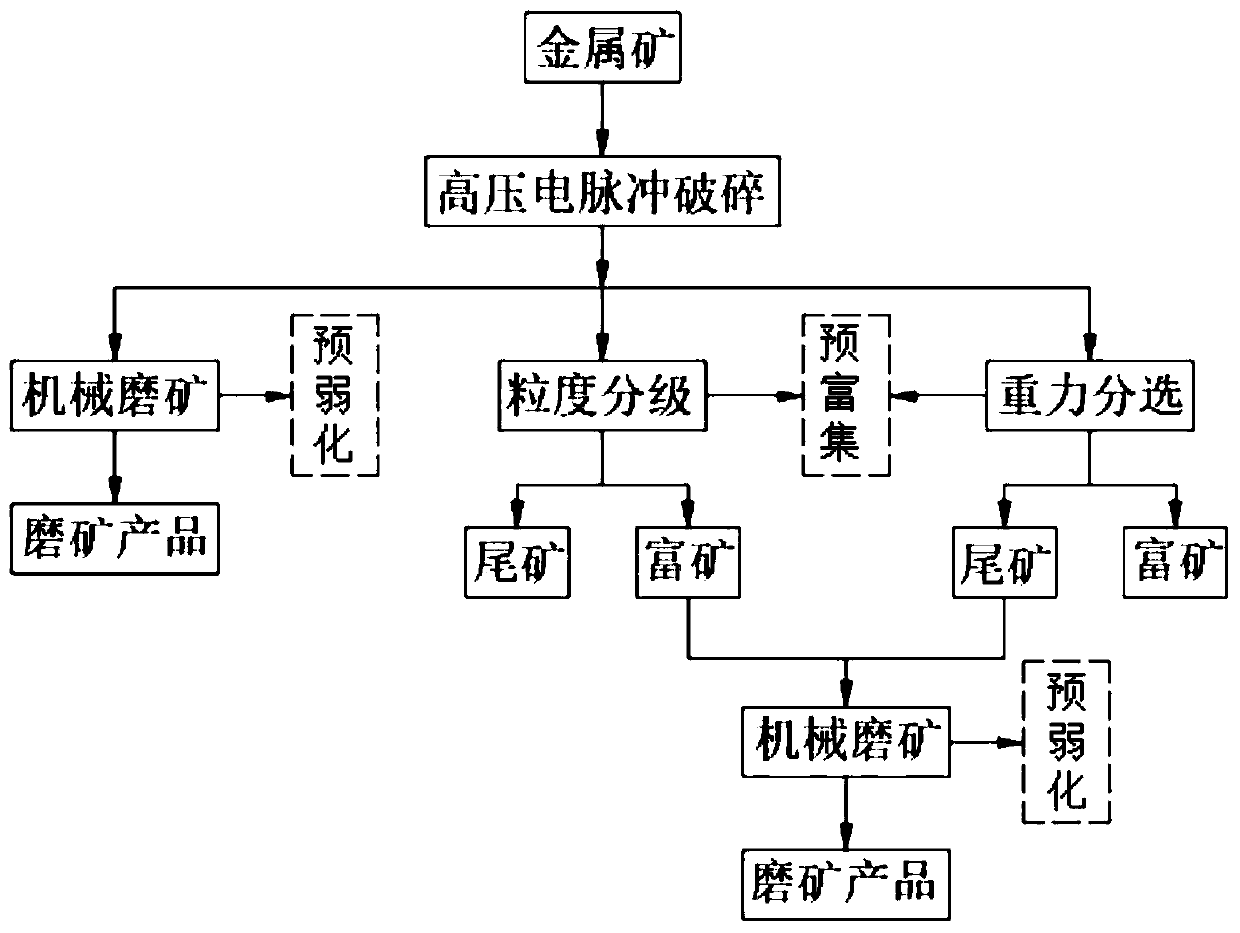

[0024] Such as figure 1 As shown, the metal ore enters the high-voltage electric pulse device for pre-weakening treatment, and the ore is processed with 1 to 2 pulses at a voltage of 170kv. The weakened ore enters the grinding device for grinding, and the ground material enters the sieve The sub-device (200 mesh) is used for inspection screening, and the materials that do not meet the requirements are returned to the grinding device for re-grinding. The screened material enters the cyclone for classification, the coarse grade enters the grinding equipment for grinding and returns to the cyclone, the fine grade enters the flotation machine for rough separation, and the rough separation concentrate enters the flotation machine for a beneficiation; once The selected concentrate enters the flotation machine for secondary selection, the primary concentrated tailings and the primary scavenging concentrate return to roughing; the secondary concentrated concentrate is concentrated and...

Embodiment 2

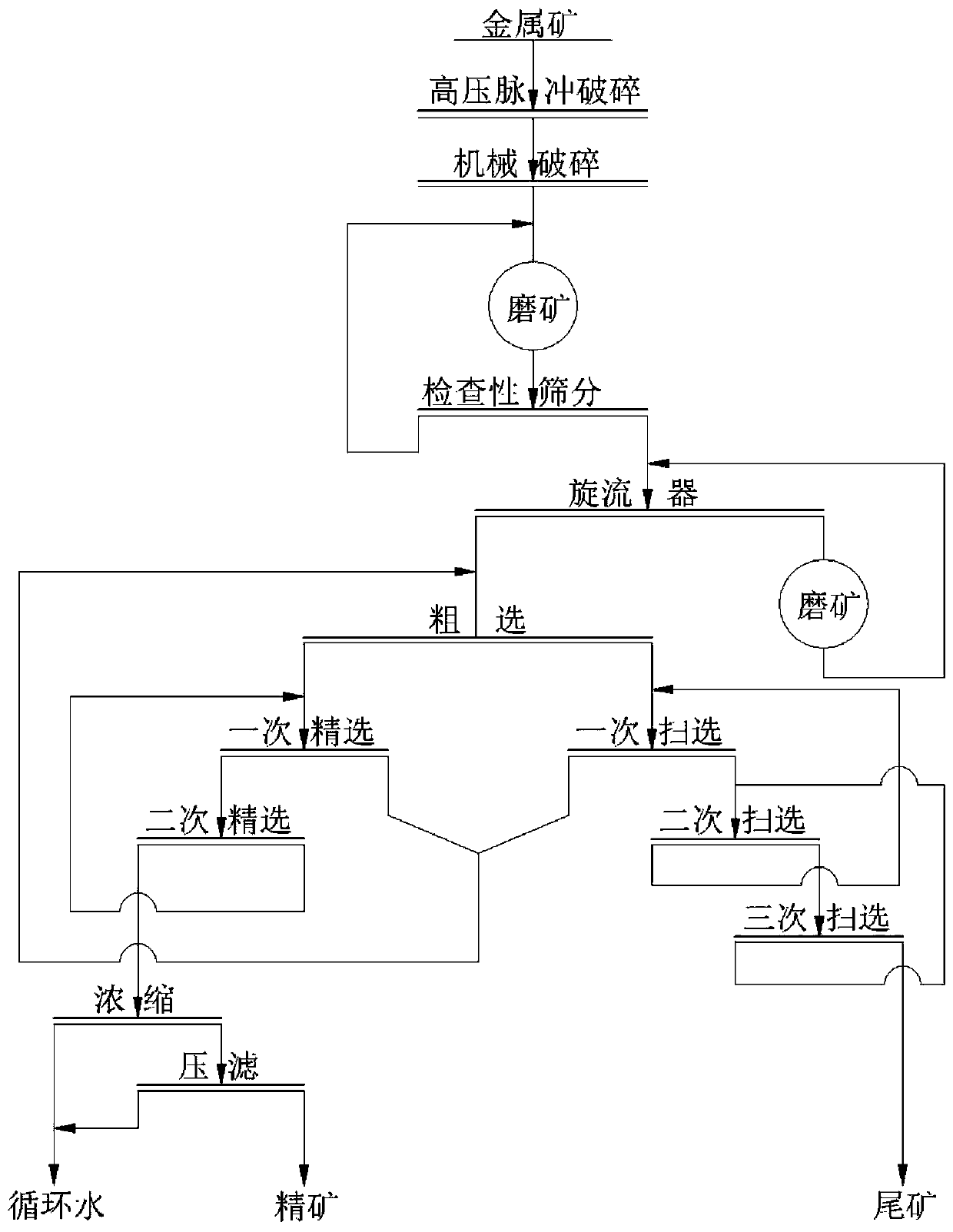

[0026] Such as figure 2 As shown, the metal ore enters the high-voltage electric pulse device for preliminary crushing, and the crushed material enters the screening device (13mm) for classification. The voltage of the high-voltage electric pulse device is 150kv, and the number of pulses is gradually increased until the proportion of -13mm material up to 70%. Due to the selectivity of high-pressure pulse crushing, coarse-grained grades can be directly discharged as tailings, and fine-grained grades enter the crusher for further crushing. The crushed ore enters the ore grinding device for grinding, and the ground material enters the screening device for inspection screening, and the material that does not meet the requirements returns to the ore grinding device for re-grinding. The screened material enters the cyclone for classification, the coarse grade enters the grinding equipment for grinding and returns to the cyclone, the fine grade enters the flotation machine for roug...

Embodiment 3

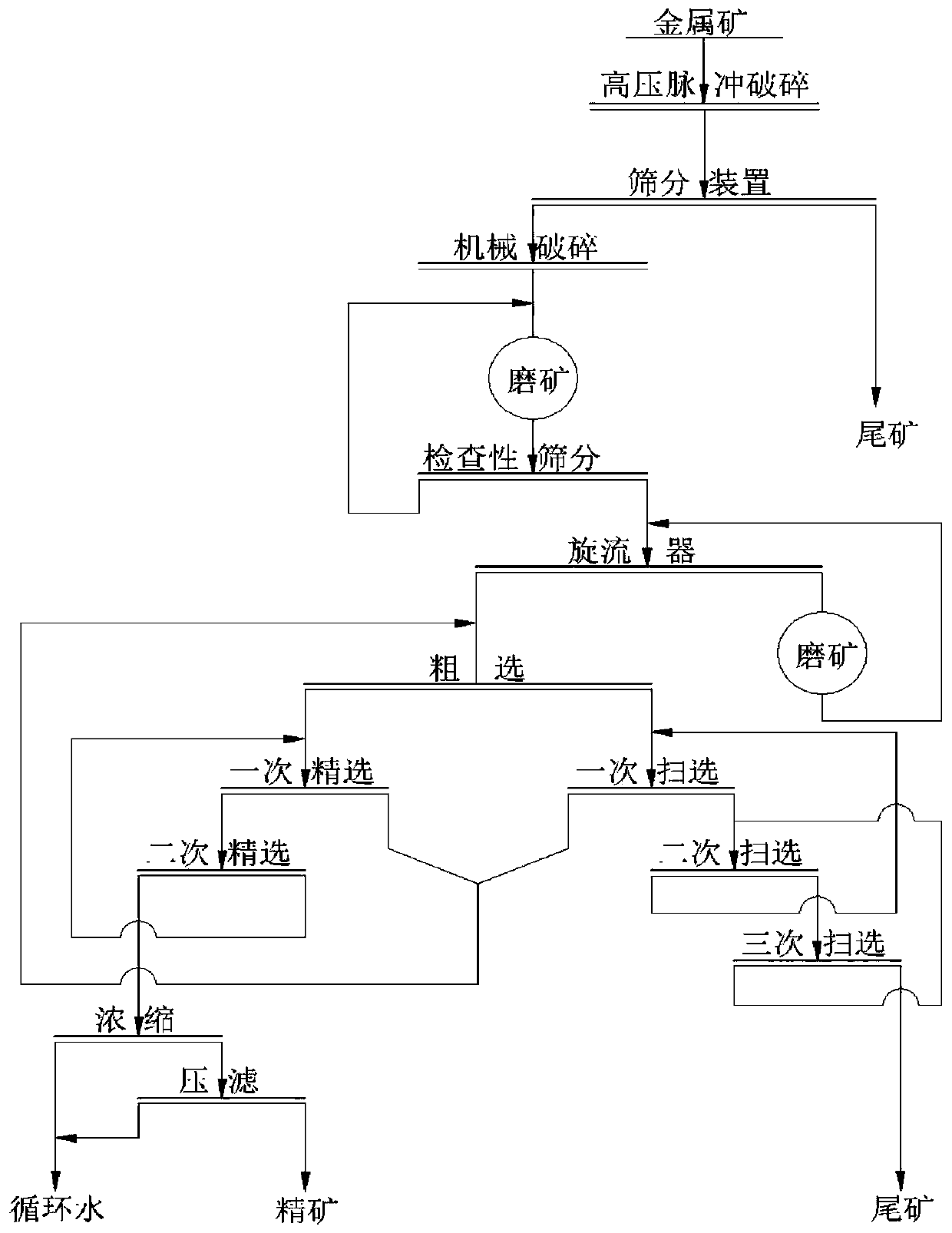

[0028] Such as image 3 As shown, the metal ore enters the high-voltage pulse device for preliminary crushing. The crushing voltage is 150kv, and the number of pulses is gradually increased to more than 95%. The material passes through the lower screen (13mm) of the high-voltage pulse device. The material is well dissociated, and the crushed material enters the gravity separation device for separation, the light product can be directly discharged as tailings, and the heavy product enters the crusher for further crushing. The crushed ore enters the grinding device for grinding, and the ground material enters the screening device (200 mesh) for inspection screening, and the material that does not meet the requirements returns to the grinding device for re-grinding. The screened material enters the cyclone for classification, the coarse grade enters the grinding equipment for grinding and returns to the cyclone, the fine grade enters the flotation machine for rough separation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com