Method for reducing fine powder rate of titanium residue breaking

A technology of titanium slag and fine powder, which is applied in the field of titanium slag crushing and metal smelting, which can solve the problems of waste of resources, large fluctuations, unstable content of fine particles, etc., and achieve the effect of reducing waste of resources and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

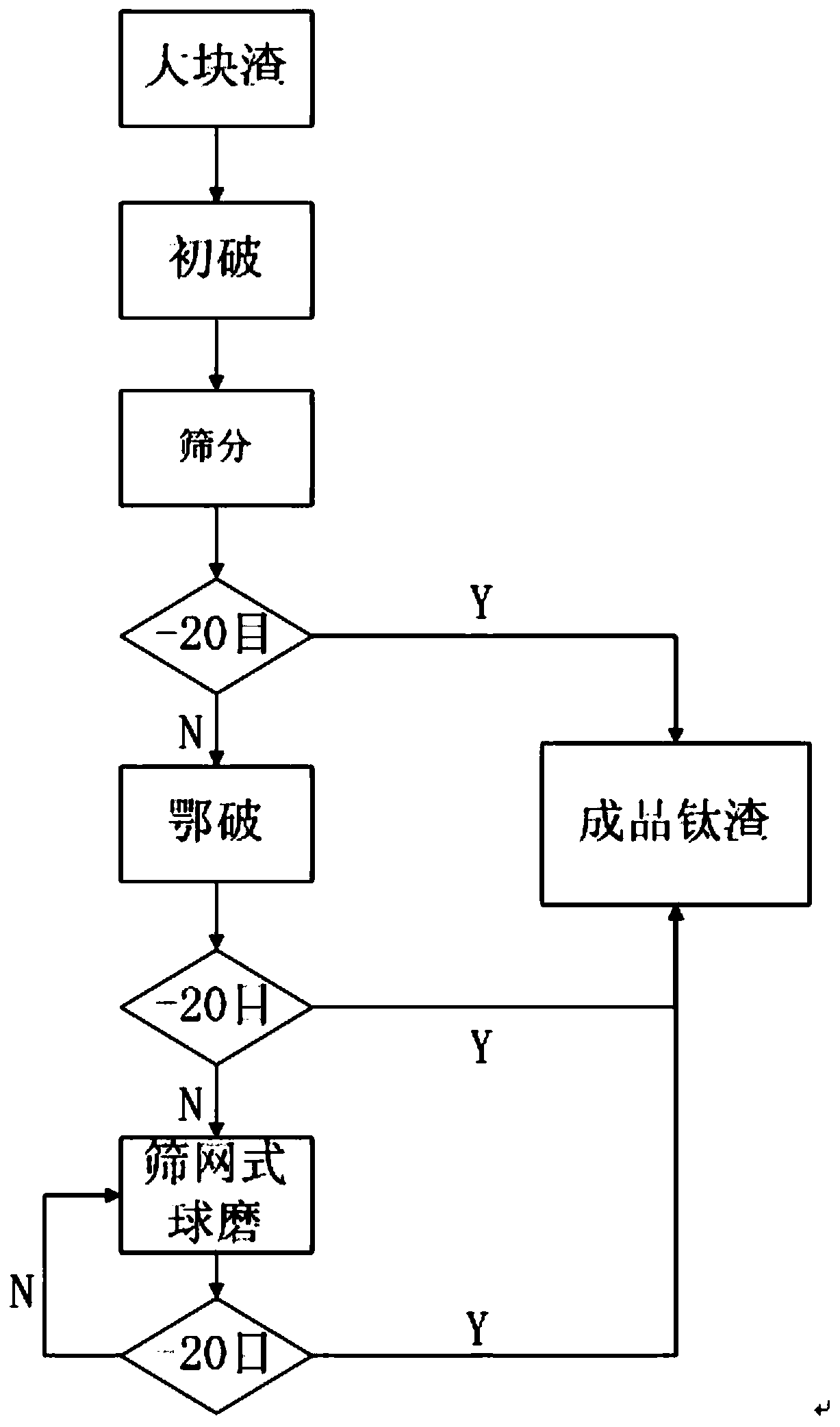

[0025] At present, the primary product of electric furnace smelting titanium slag is usually a large slag ingot with a length of 2.5m, a width of 1.5m, and a height of about 1m. The titanium slag finished products crushed by the traditional process of primary crushing (mechanical or falling ball, etc.) + jaw crusher + hammer crushing, usually has a -200 mesh content of about 25-30%. After the crushing control is carried out by adopting the method and equipment, the -200 mesh content of the finished slag is stabilized at 5% to 8%. The specific implementation method is as follows:

[0026] (1) After the large slag ingot is cooled for 24 hours, use a falling ball to break the large slag ingot into small slag blocks with a diameter of less than 200mm. The small slag is transferred to the first screening process by the loader, and screened through a 20-mesh drum sieve. The undersize is usually within 5%, and is directly sold as finished slag, and the oversize is directly connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com