Hydraulic drive percussion primary-secondary drilling bit

A kind of technology of mother-in-law drill bit and punching, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of side tooth shedding service life, poor chip removal of hydraulic punching and rotating drill bit, and repeated crushing of cuttings, so as to prevent Effects of shedding, reduced chance of returning to the bottom, reduced size and intensity of eddies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

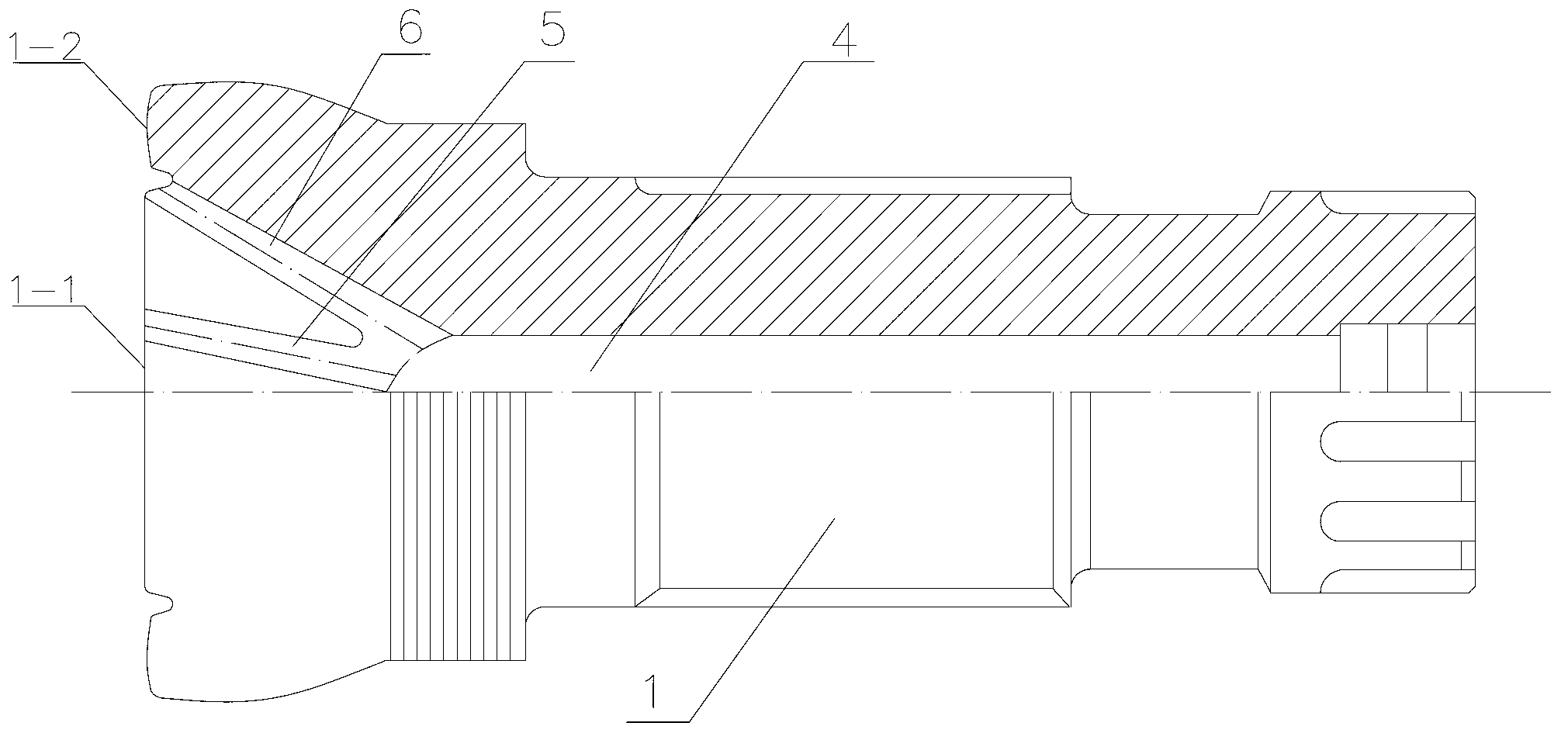

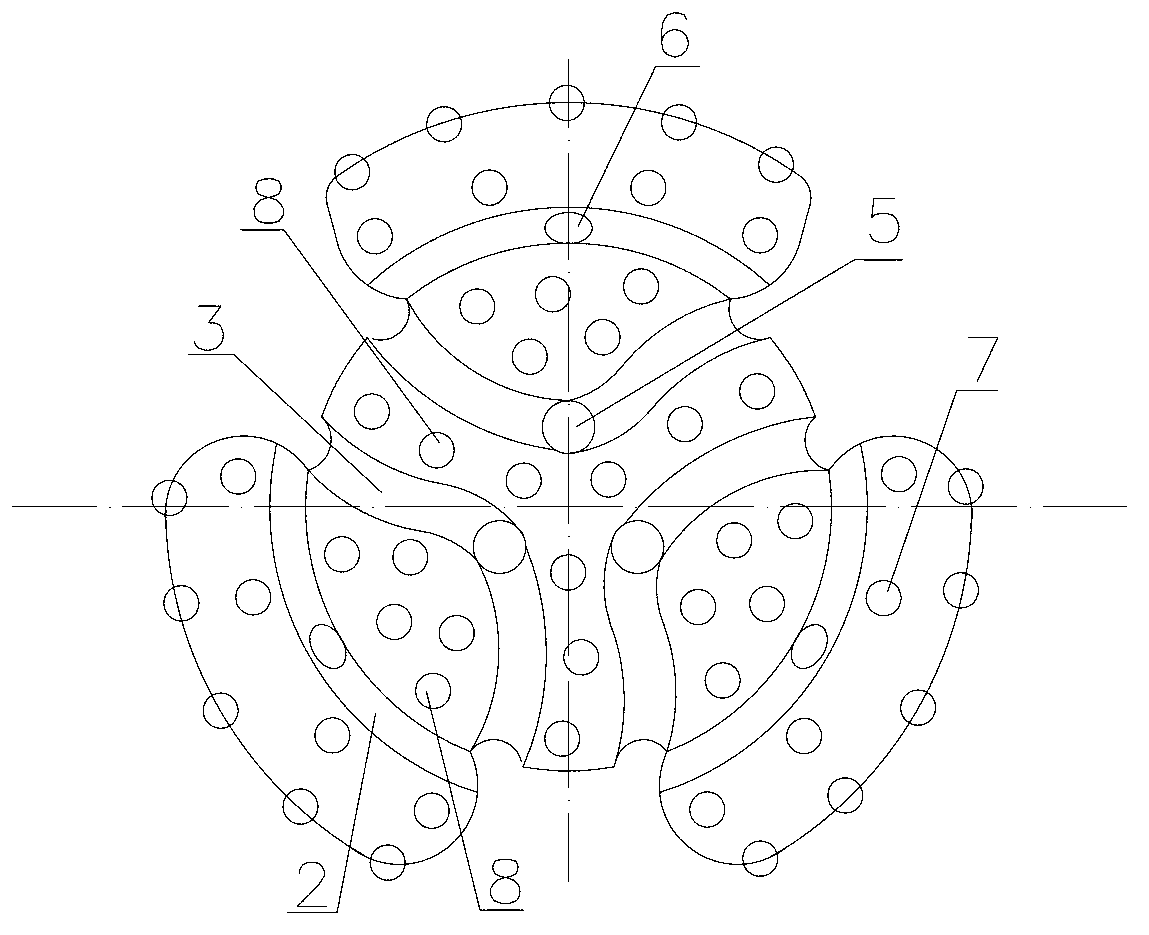

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0022] Such as Figure 1-4 As shown, it is an embodiment of the hydraulic punching and spinning female bit of the present invention, which includes a bit body 1 and teeth arranged on the end face of the bit body 1. The end face of the bit body 1 is a step-separated type, and its orthographic projection is a three-piece type fan-shaped, the end face is divided into a central circular end face 1-1 and three fan-shaped end faces 1-2, the fan-shaped end faces 1-2 are evenly distributed on the outer ring of the central circular end face 1-1, The root of each leaf-shaped end surface 1-2 is provided with an arc-shaped chip removal groove 2, and the three arc-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com