Fabricated integrated building and production method thereof

A manufacturing method and building technology, which can be applied to building structures, buildings, building components, etc., can solve the problems of complex construction, low self-strength, time-consuming, etc., and achieve the effects of shortened construction period, superior seismic performance, and simple and convenient combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

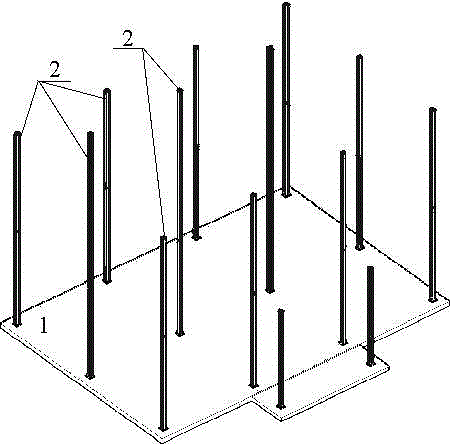

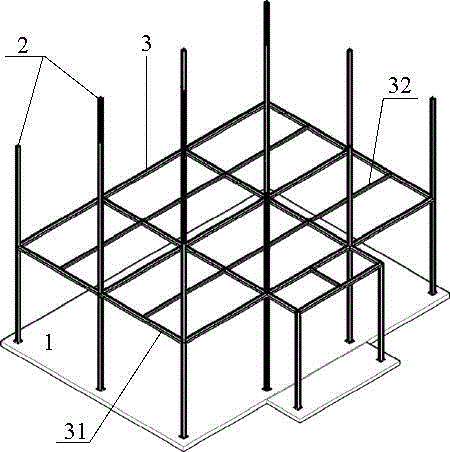

[0058] A prefabricated integrated building, comprising a foundation 1, columns 2, floor beams 3, floor panels 41, floor composite panels 42, exterior wall panels 51, interior wall panels 52, roof trusses 61 and roof panels 62, such as Figure 1 to Figure 21 As shown, the specific structure is:

[0059] The foundation 1 is laid on the foundation, and the columns 2 are vertically fixed on the foundation 1;

[0060] The floor beam 3 is a frame structure, and the floor beam 3 is arranged in layers along the vertical direction, and the floor beams 3 of each floor are all arranged horizontally. The 2nd floor, the 3rd floor, ... the nth floor, the floor beam 3 comprises the inter-column beam 31 and the inter-beam beam 32, and the two ends of the inter-column beam 31 are respectively fixed on a column 2, and the two ends of the inter-beam beam 32 The ends are respectively fixed on an inter-column beam 31, and stairs 33 are used to connect the floor beam 3 and the foundation of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com