Rope-type overall-horizontal-pull ecological water sluice gate with laminated beams and operation method of water sluice gate

A sluice gate, the overall technology, applied in the field of rope-type integral cross-tensioned stacked beam ecological water intake gate, can solve the problems of reduced service life, inability to purify and filter, and downstream water pollution, so as to reduce the content of dirt and sediment and increase the use of water Good effect of life and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

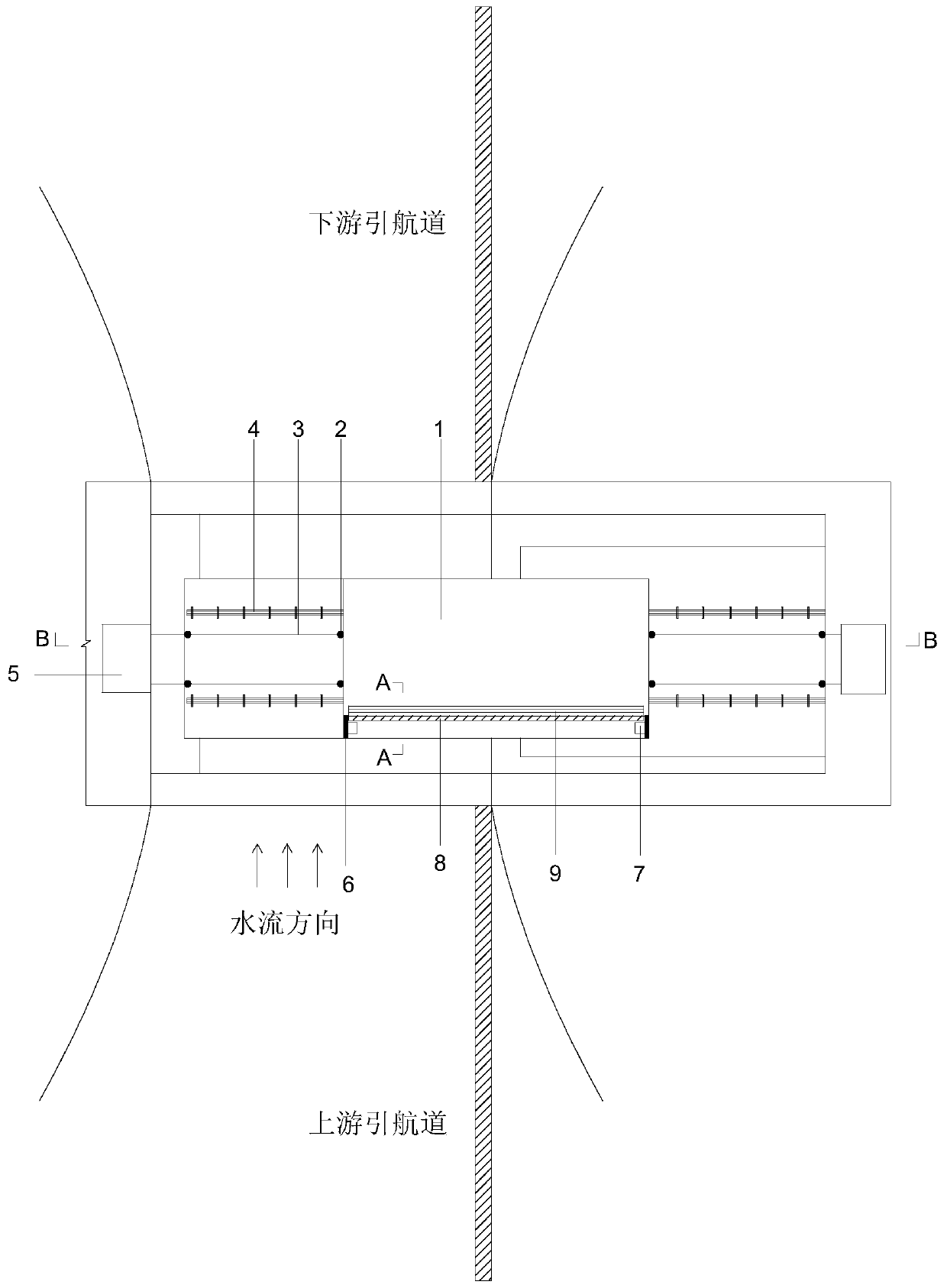

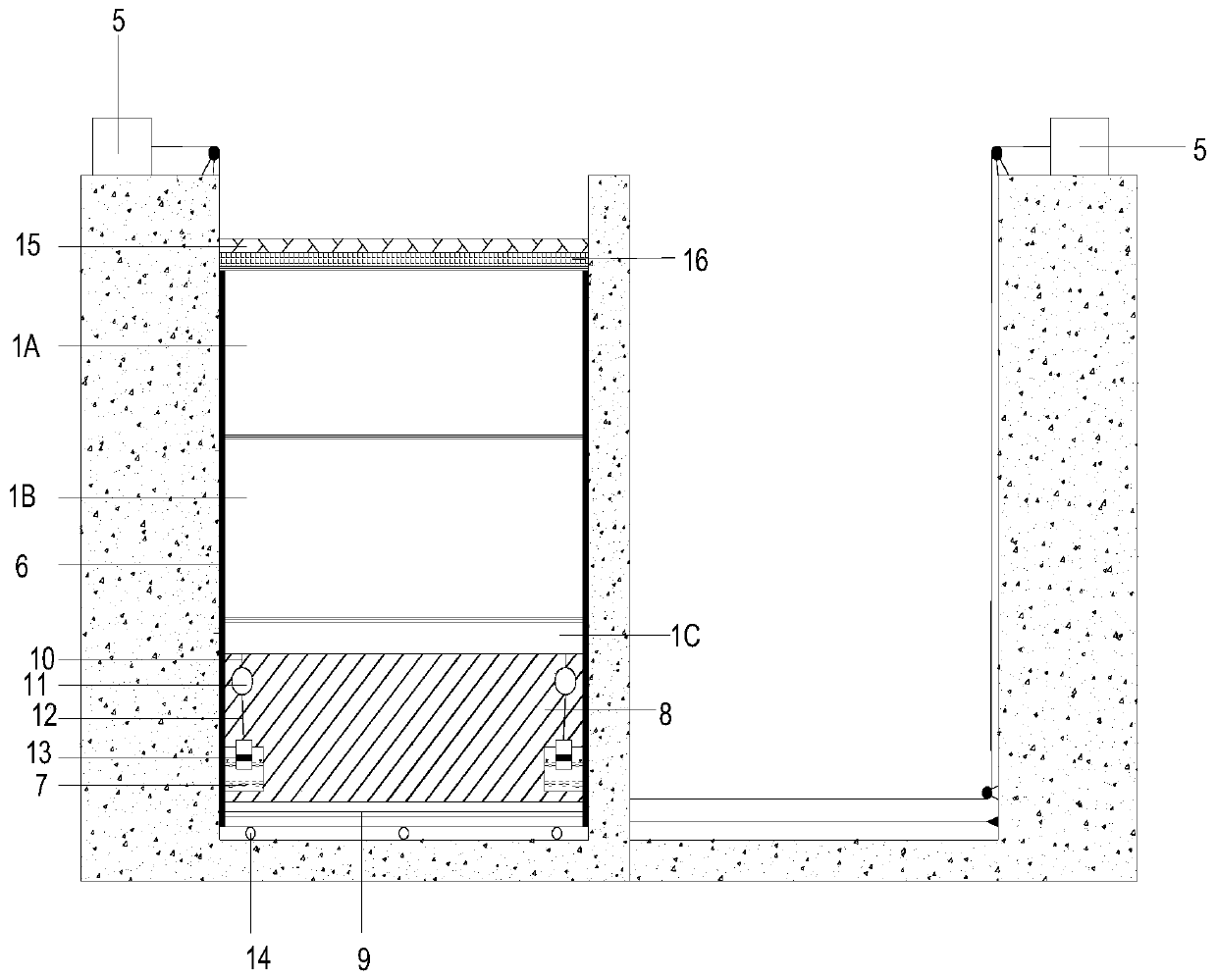

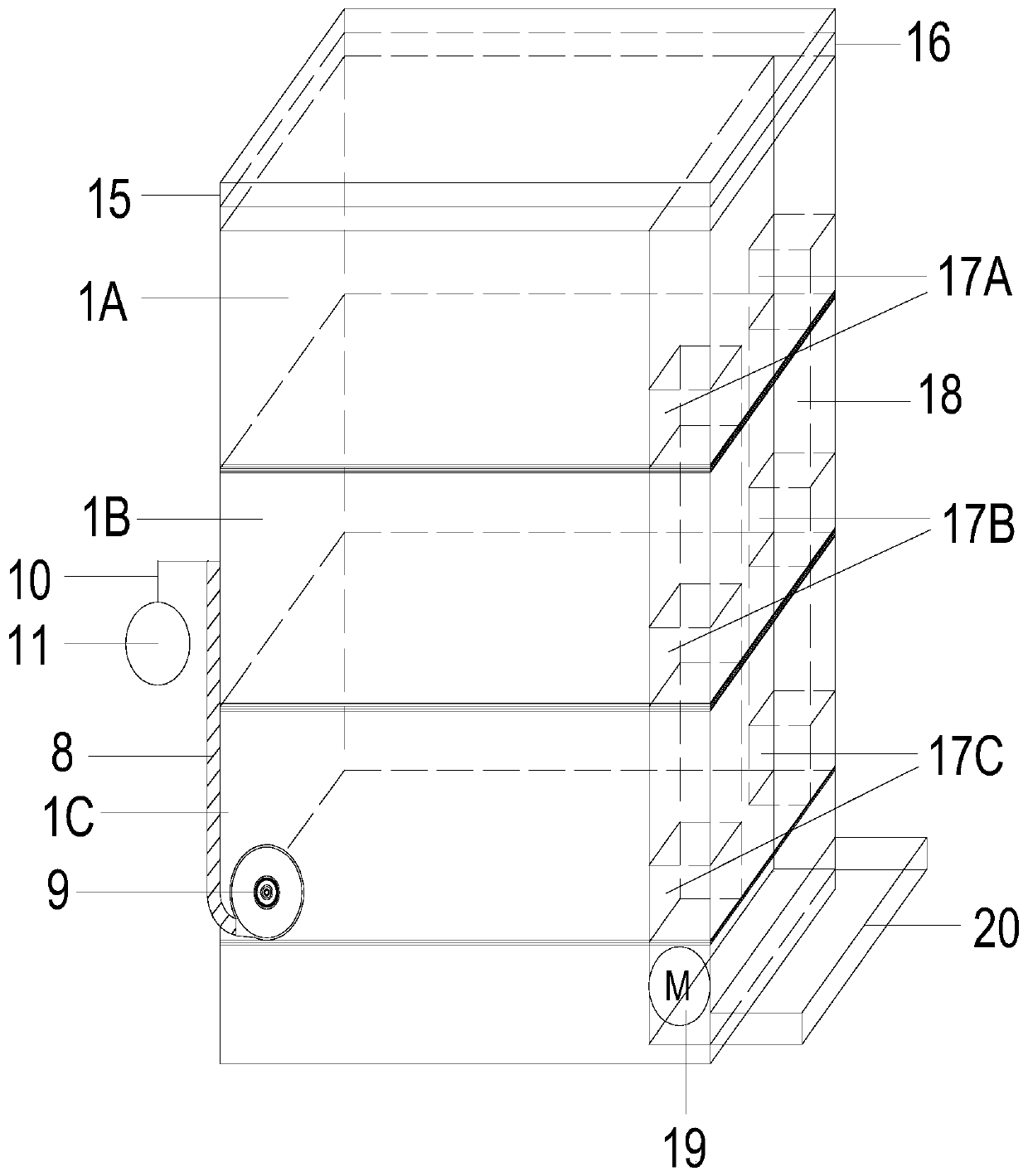

[0047] The real-time mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0048] Such as Figure 1 to Figure 12 as shown,

[0049]The present invention relates to a kind of rope-type integral transverse tension stacked beam ecological water intake gate, comprising: gate frame 1 (1A top empty box gate, 1B middle empty box gate, 1C bottom empty box gate), pulley block 2 (2A fixed end, 2B tension wheel, 2C guide wheel, 2D force transmission wheel), wire rope 3, track 4, power mechanism 5, detachable steel plate 6, detachable piston box 7, rolling door leaf 8, detachable rolling door box 9, connecting rod 10, floating ball 11. Length-adjustable air pipe 12, piston 13, roller 14, solar panel 15, power storage device 16, compression pipeline water inlet 17 (17A top empty box gate compression pipeline water inlet, 17B middle empty box gate compression pipeline water inlet, 17C Bottom empty box gate compression pipe water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com