Fabricated reinforced concrete angle brace frame and construction method thereof

A reinforced concrete and construction method technology, applied in truss structures, protective buildings/shelters, building components, etc., can solve the problems of high construction dimensional accuracy, long construction period, complex procedures, etc., and shorten the construction period , small impact on cost, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings and specific preferred embodiments.

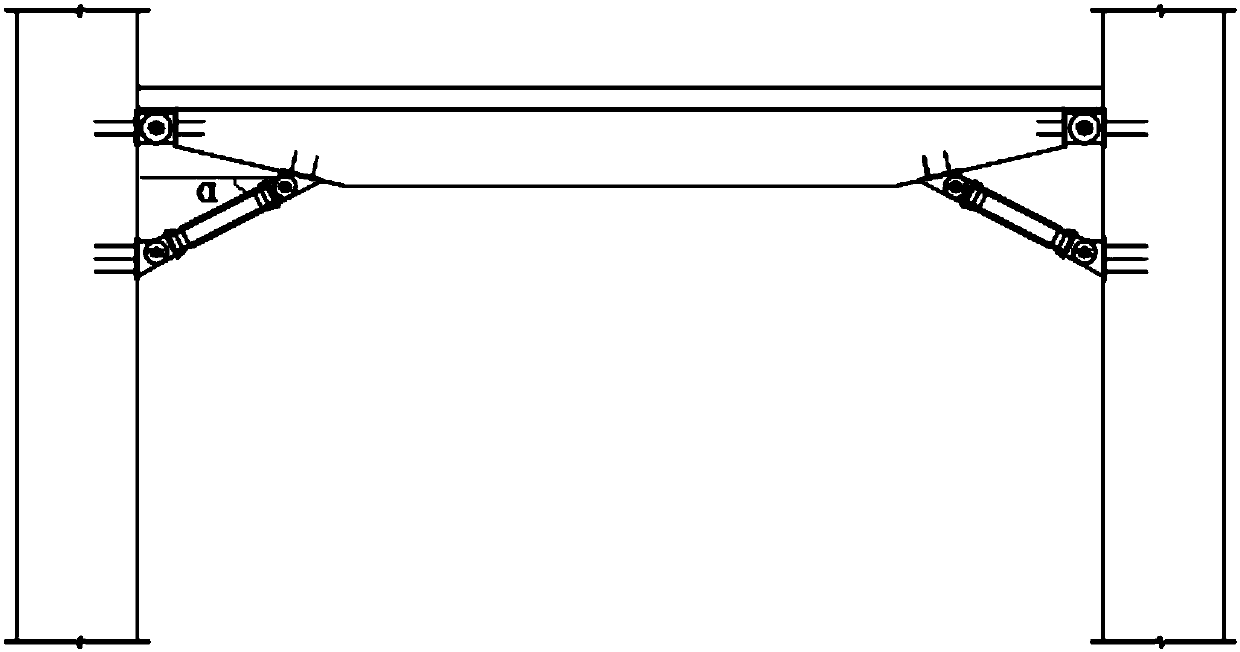

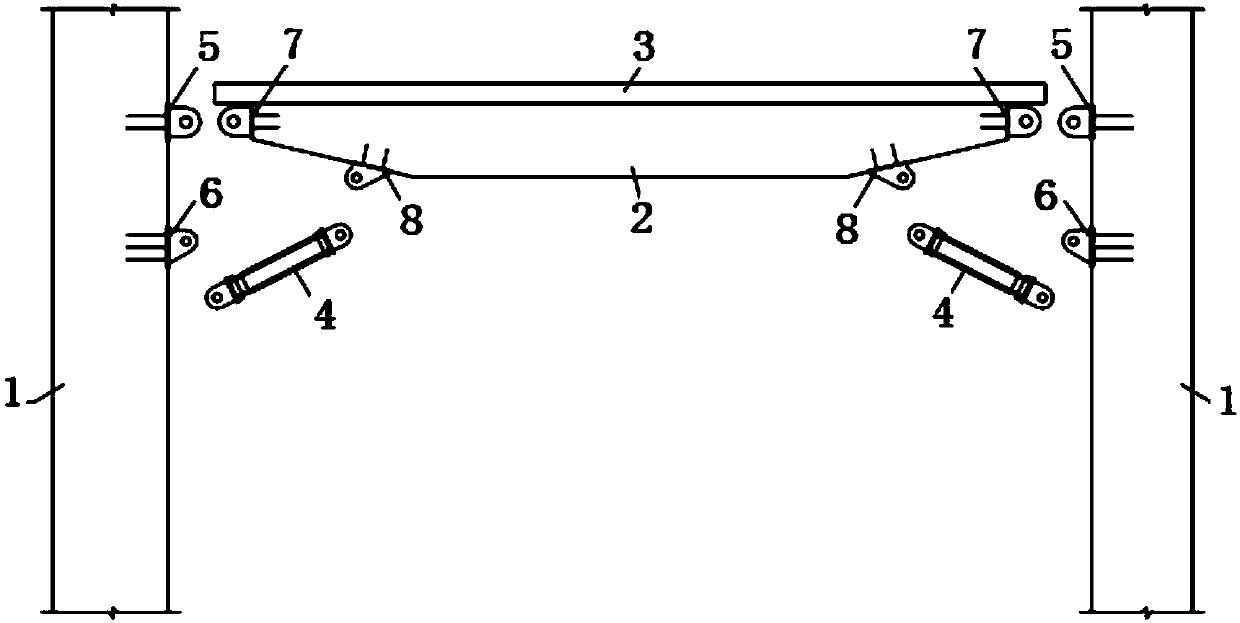

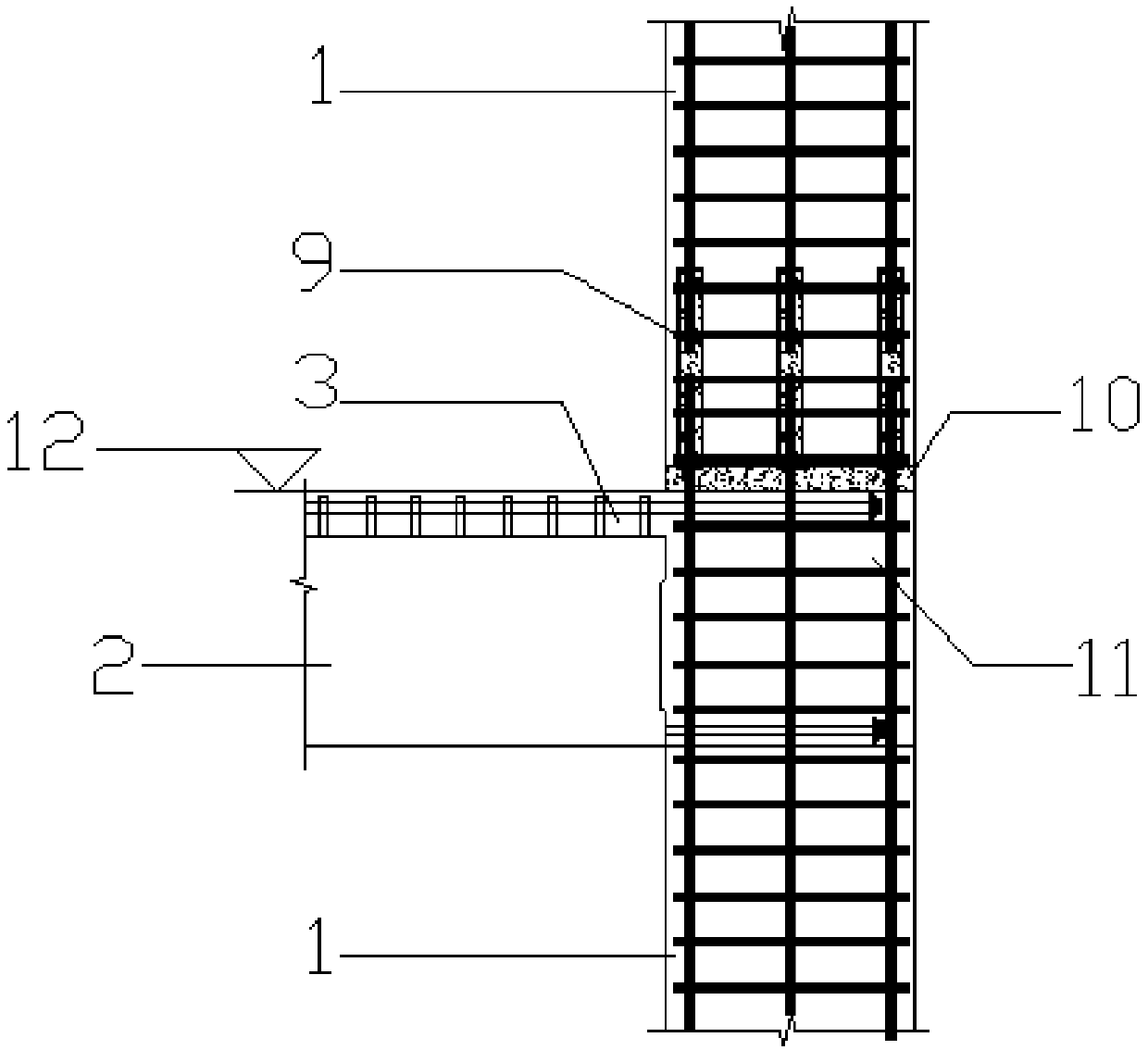

[0037] Such as figure 1 with figure 2 As shown, a fabricated reinforced concrete gusset frame includes a prefabricated column 1, a laminated beam, and an anti-buckling support 4.

[0038] The composite beam is arranged horizontally, and the composite beam includes a precast beam 2 and a post-poured concrete 3 on the top of the precast beam.

[0039] Both ends of the precast beam are preferably gradually decreasing beams with variable cross-sections. The setting of variable cross-section beams is convenient for installation, and can increase the horizontal angle α between the anti-buckling support and the prefabricated composite beam, and the supporting effect is better; in addition, the use of reinforced concrete can be saved.

[0040] The two ends of the precast beam are hinged with the precast columns on both sides, and the bottom of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com