Method for prefabricating camber of large-scale steel laminated beam web

A beam web and camber technology, applied in the field of large-scale steel stacked beam manufacturing, can solve the problems of inability to correct, large amount of correction, huge structure, etc., achieve high practical value, and ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

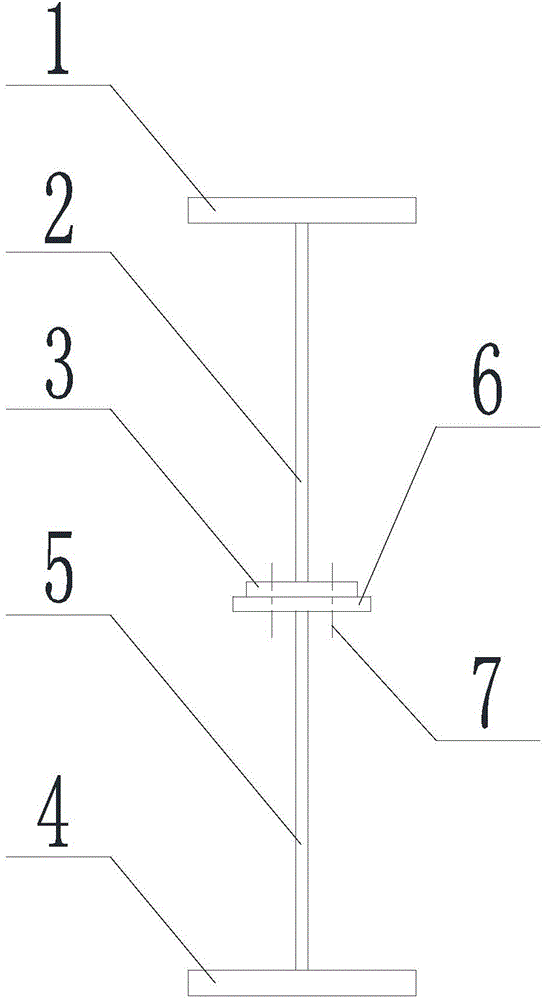

[0020] Attached below Figure 1-7 An embodiment of the present invention is described.

[0021] A method for prefabricating the web camber of a large-scale steel stacked beam includes the following steps:

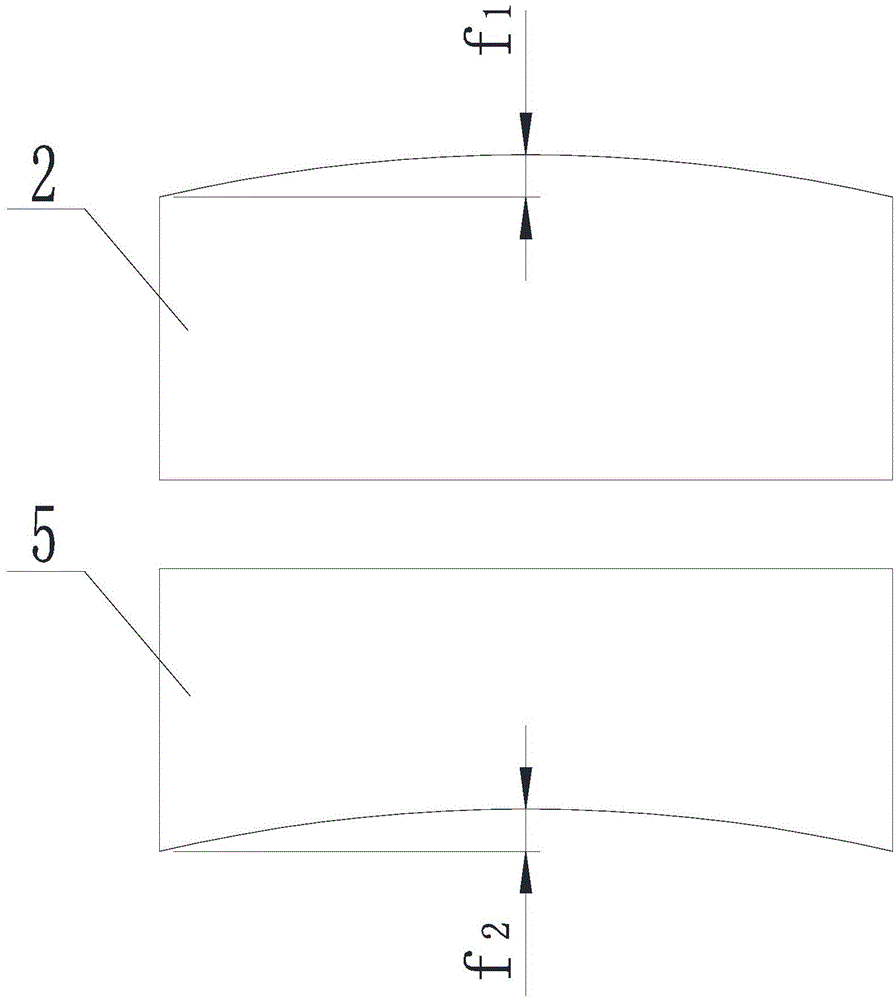

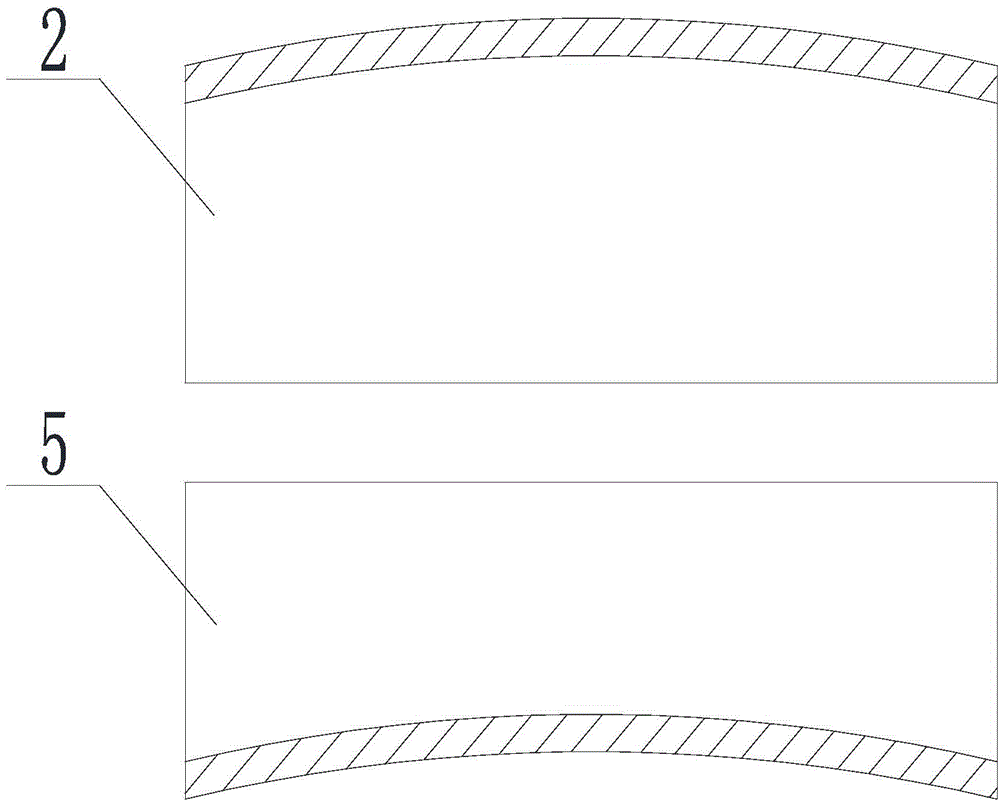

[0022] 1. First, the upper beam web 2 and the lower beam web 5 are blanked on the sides of the upper beam flange plate 1 and the lower beam flange plate 4 respectively according to the ideal curve of the prefabricated camber, and the upper beam web 2 and the lower beam web are 5. The upper beam laminated slab 3 and the lower beam laminated slab 6 sides are cut according to a straight line without prefabricating the camber; specifically, a semi-automatic cutting machine is used to cut and blank the material with a combination of shorter fold lines instead of arc curves. Make the camber of the upper beam web 2 be f1, and the camber of the lower beam web 5 be f2;

[0023] 2. Using the principle of flame rectification, the upper beam web 2 and the lower beam web 5 are band-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com