Prefabricated, assembled and integrated type special-shaped column structure and jointing construction method thereof

A technology for prefabricated assembly and special-shaped columns, which is applied in building construction, construction, and building materials processing, etc., can solve problems such as construction difficulties, dense reinforcement, and incompact concrete vibrating, so as to shorten the construction period, solve difficult vibrating, Eliminate the weak effect of nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

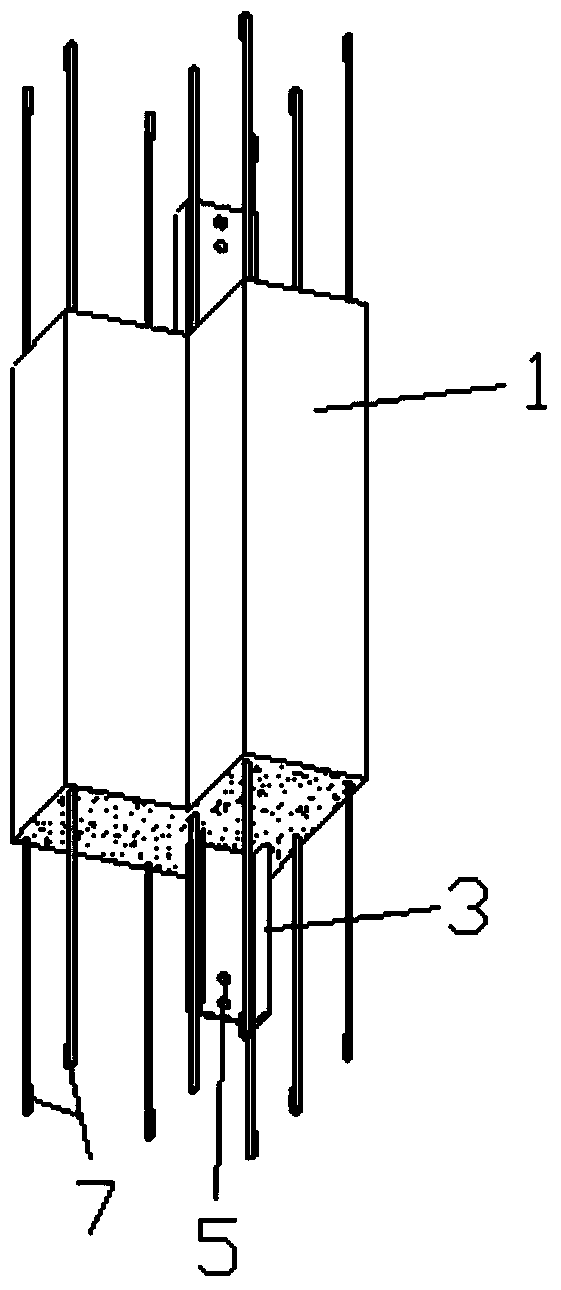

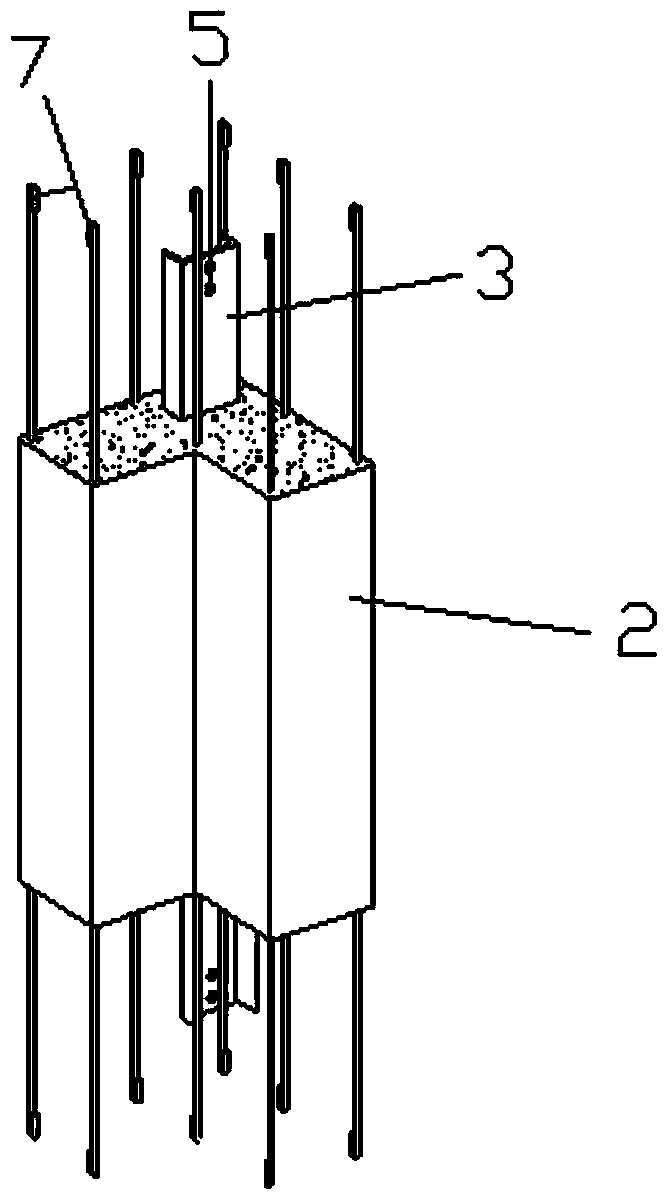

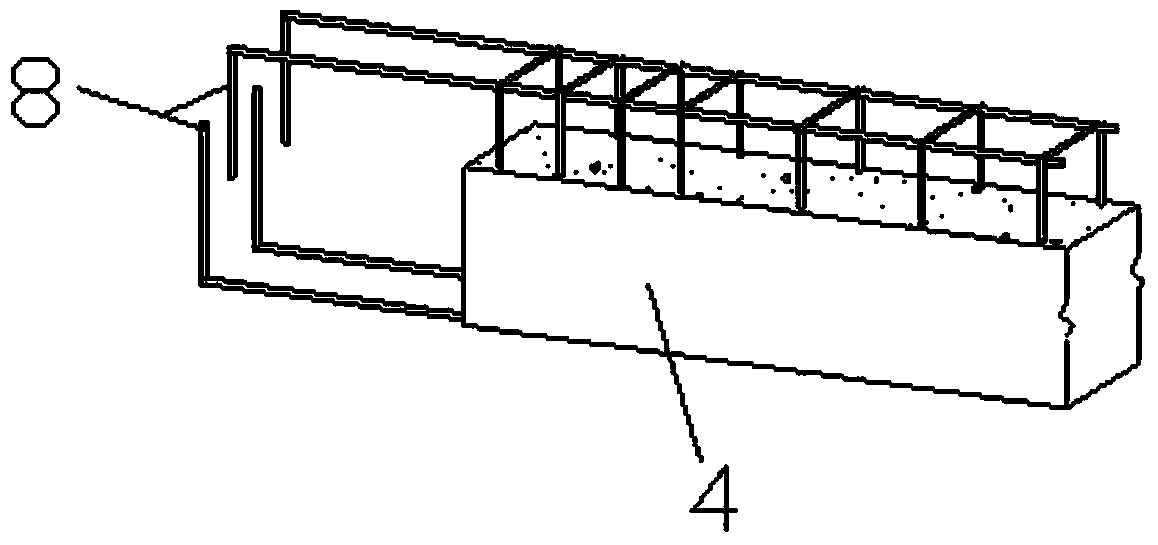

[0032] Such as figure 1 , 2 , 3, 4 and 5 show: a prefabricated assembled monolithic special-shaped column structure, which comprises a prefabricated upper column 1, a prefabricated lower column 2 and a prefabricated composite beam 4;

[0033] The prefabricated upper column 1 and the prefabricated lower column 2 are pre-embedded with channel steel 3, and there are reserved bolt holes 5 on the channel steel 3, and the adjacent prefabricated upper column 1 and prefabricated lower column 2 are connected by bolts through the channel steel 3. Together, a special-shaped column with a cast-in-place area is formed up and down, and the cast-in-place area is partially provided with encrypted stirrups; the prefabricated composite beam 4 is anchored in the special-shaped column through the longitudinal reinforcement of the beam; two adjacent The cast-in-place areas of the prefabricated upper column 1, the prefabricated lower column 2 and the uncast concrete part of the prefabricated compo...

Embodiment 2

[0037] Such as Image 6 , 7 , 8 and 9, the difference between this embodiment and embodiment 1 is that the arrangement of the channel steel 3 in the prefabricated upper column 1 and the prefabricated lower column 2 is a dispersed arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com