Method for constructing reinforced-concrete prefabricated element fabricated building with frame structure system

A reinforced concrete and frame structure technology, which is applied in building construction, construction, and building materials processing, etc., can solve problems such as unreasonable structure, high construction cost, and low starting point for component installation and construction technology innovation, so as to reduce construction costs. , the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

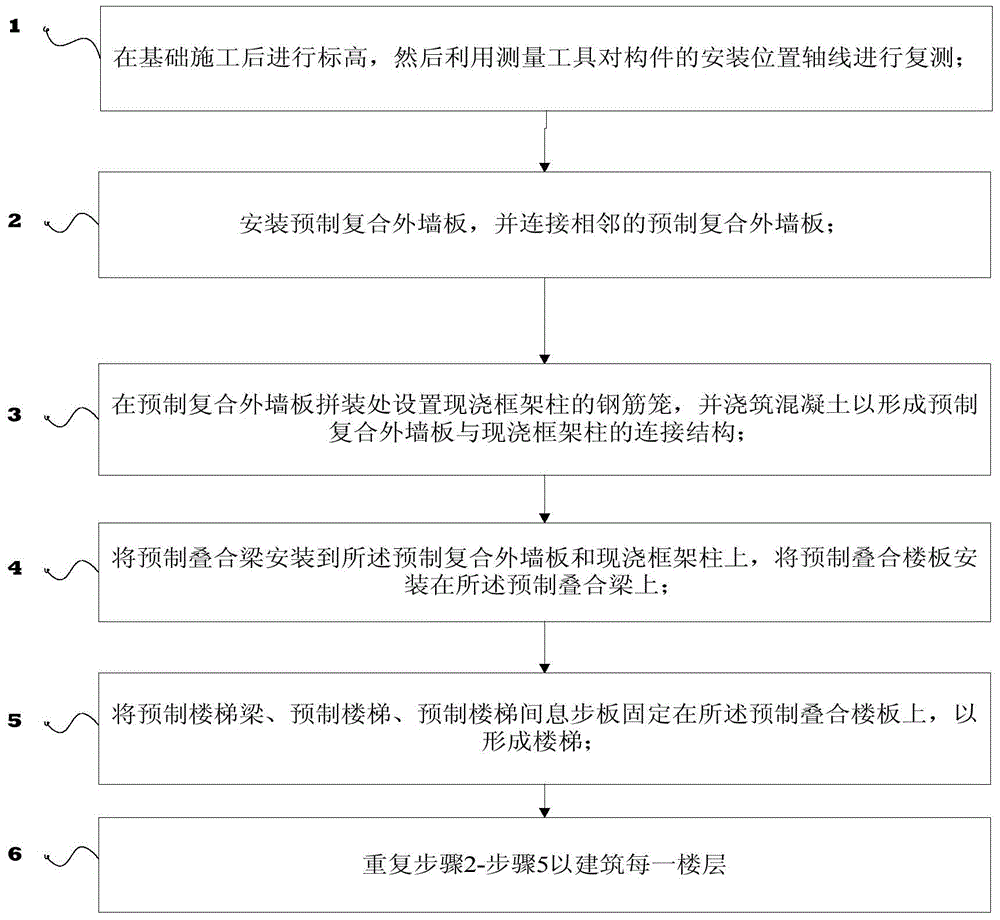

[0156] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

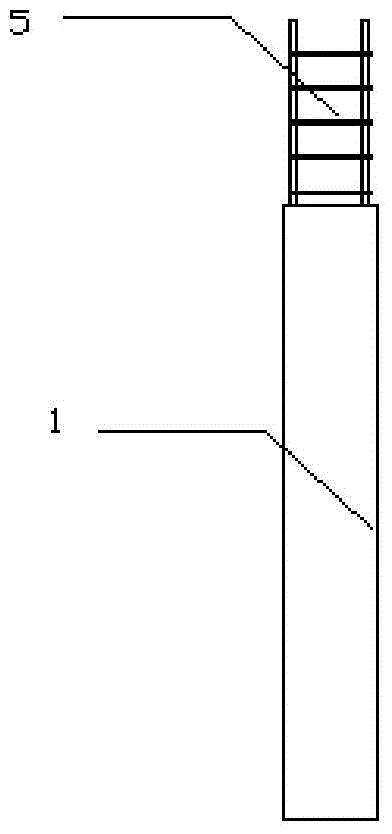

[0157] The prefabricated components used in the embodiment of the present invention include: Figure 2b The prefabricated laminated slab 21 shown; as Figure 2c The prefabricated composite exterior wall panel 24 shown; as Figure 2d Reinforced concrete prefabricated column frame 3 as shown; Figure 2e and 2f The prefabricated composite beam 13 shown; as Figure 2g Shown are prefabricated stair beams 47, prefabricated stairs 48, and prefabricated stairwell step boards 50.

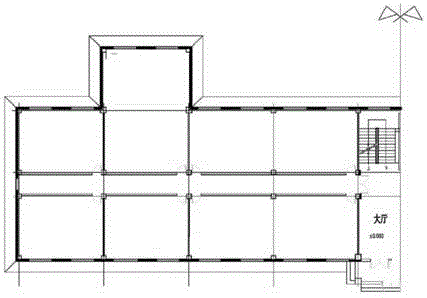

[0158] Such as Figure 24 Shown is the house infrastructure node diagram; such as Figure 25 Shown is the floor plan of the completed building; Figure 26 Shown is a corner view of the front elevation of the house; Figure 27 Shown is a section view of the house; Figure 28 Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com