Ultra-high performance concrete composite beam bridge deck slab wet joint continuous structure with template

An ultra-high-performance, wet-joint technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficulty in ensuring the quality of concrete pouring and difficulty in setting up the formwork, so as to eliminate the need for formwork loading and unloading, facilitate construction, and reduce formwork The effect of engineering quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

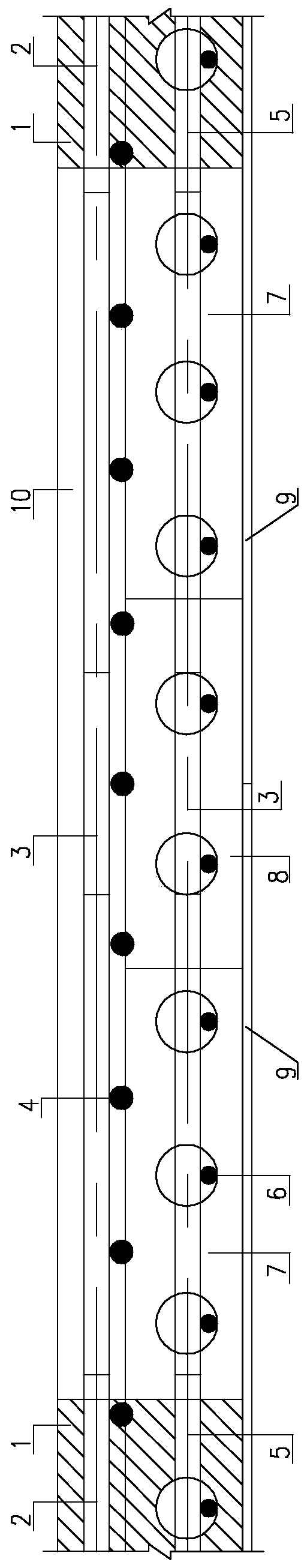

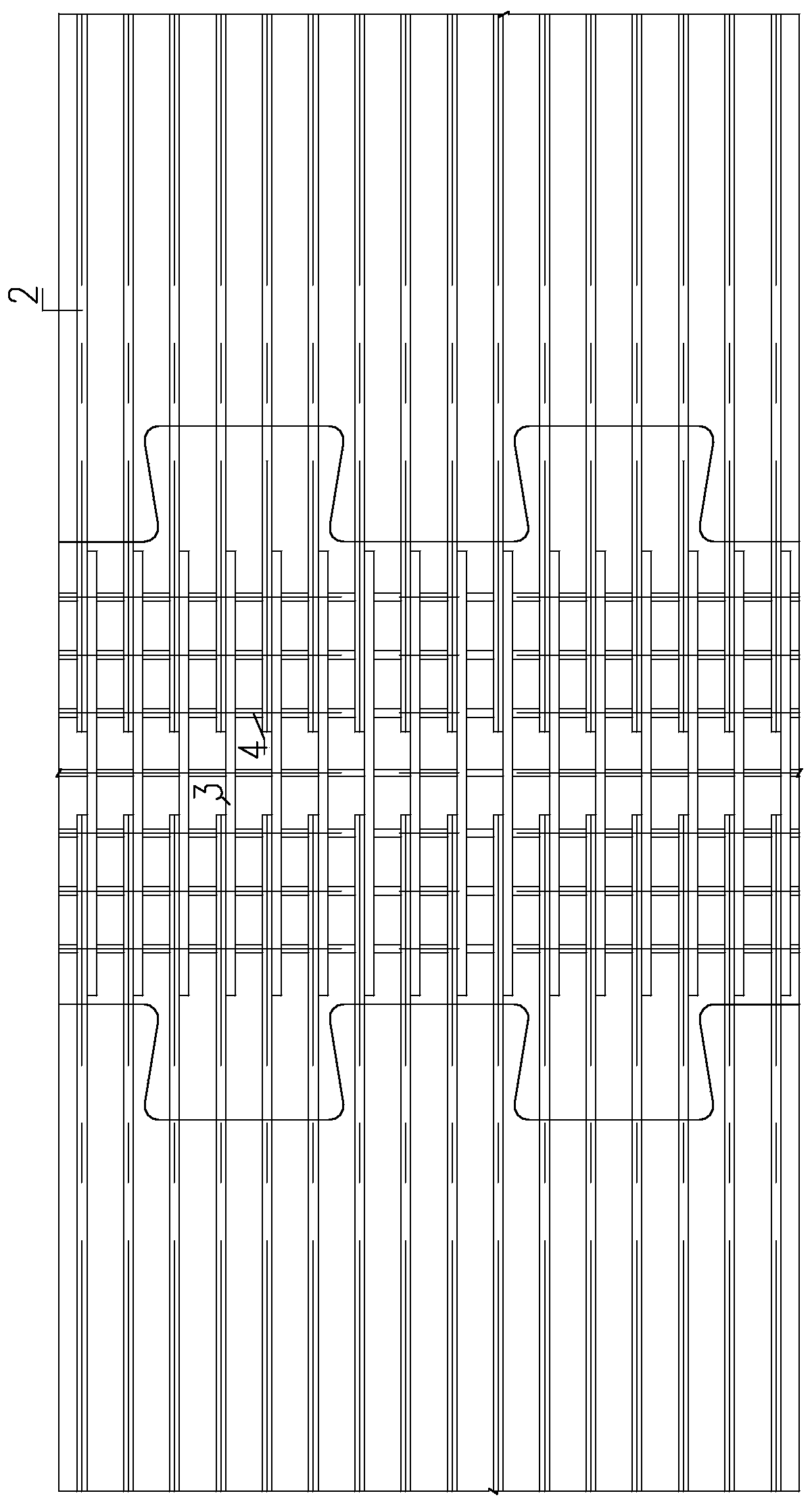

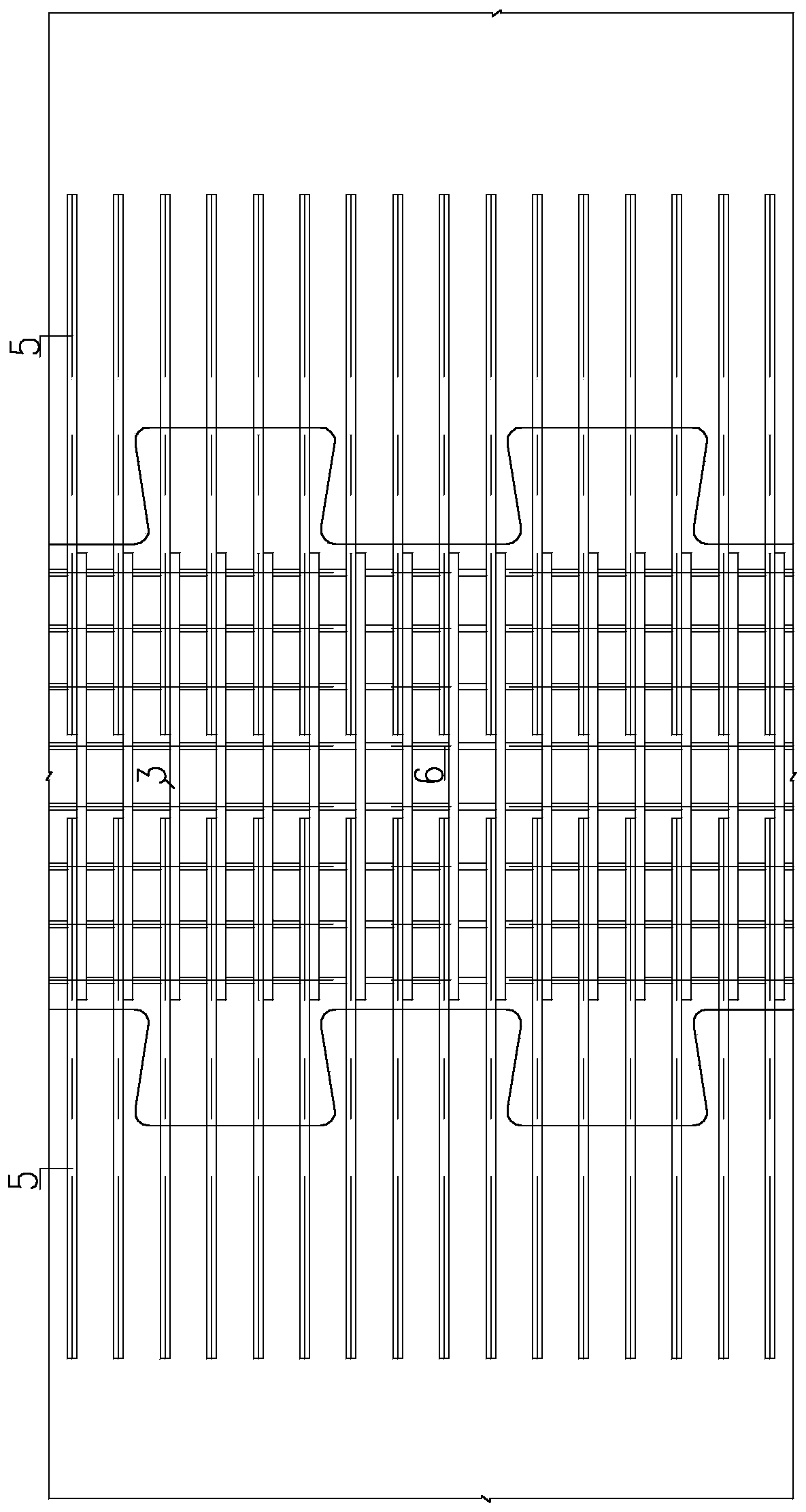

[0056] Such as Figure 1 to Figure 6 The continuous wet joint structure of ultra-high performance concrete composite beam bridge deck with its own formwork is shown, including prefabricated section, wet joint section and steel bottom formwork. The prefabricated section bridge deck is made of ultra high performance concrete material; It is the extension section of the bottom formwork of the bridge deck of the prefabricated section, which is butt welded in the middle of the wet joint, and the steel bottom formwork is used as the bottom formwork of the wet joint section; the wet joint section is supported on the steel bottom formwork, and is connected with the steel bottom formwork and The prefabricated section is poured and connected, and the wet joint section is laid continuously. The wet joint section is as thick as the bridge deck, and the same ultra-high performance concrete material as the bridge deck is used.

[0057] In this embodiment, the prefabricated section includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com