Assembling-type beam-column joint connection structure for concrete special-shaped column frame

A technology of beam-column joints and connecting structures, applied in the direction of structural elements, building components, building structures, etc.

Active Publication Date: 2016-07-13

河北省建筑科学研究院有限公司

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved by the present invention is to provide a beam-column joint connection structure of an assembled concrete special-shaped column frame, which can be easily assembled at the construction site, reduce wet work at the construction site, simplify the construc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

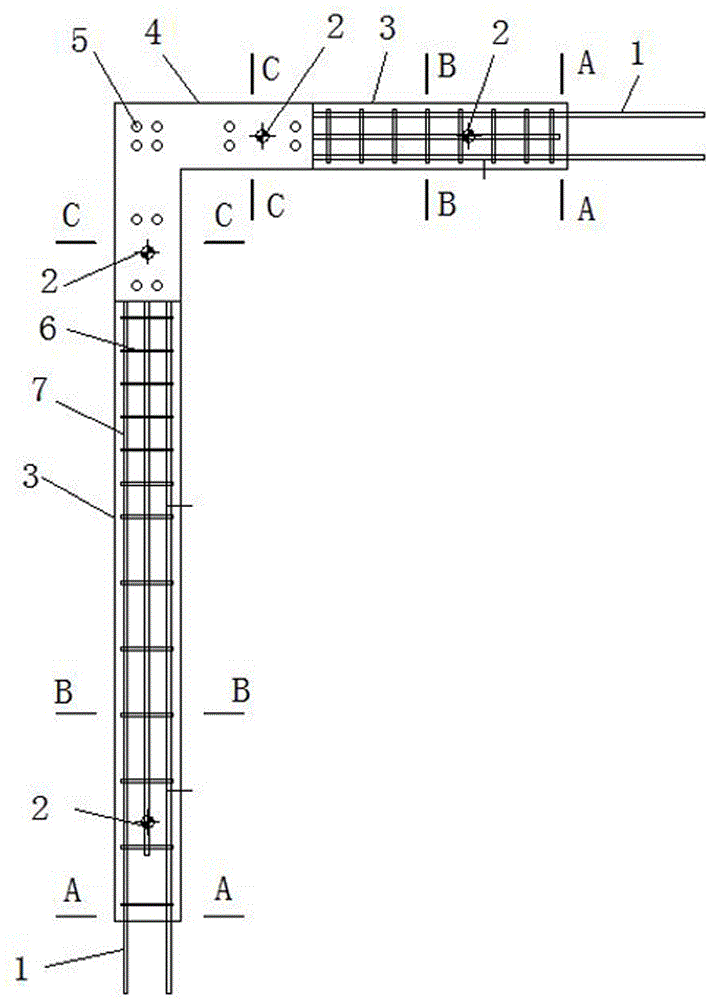

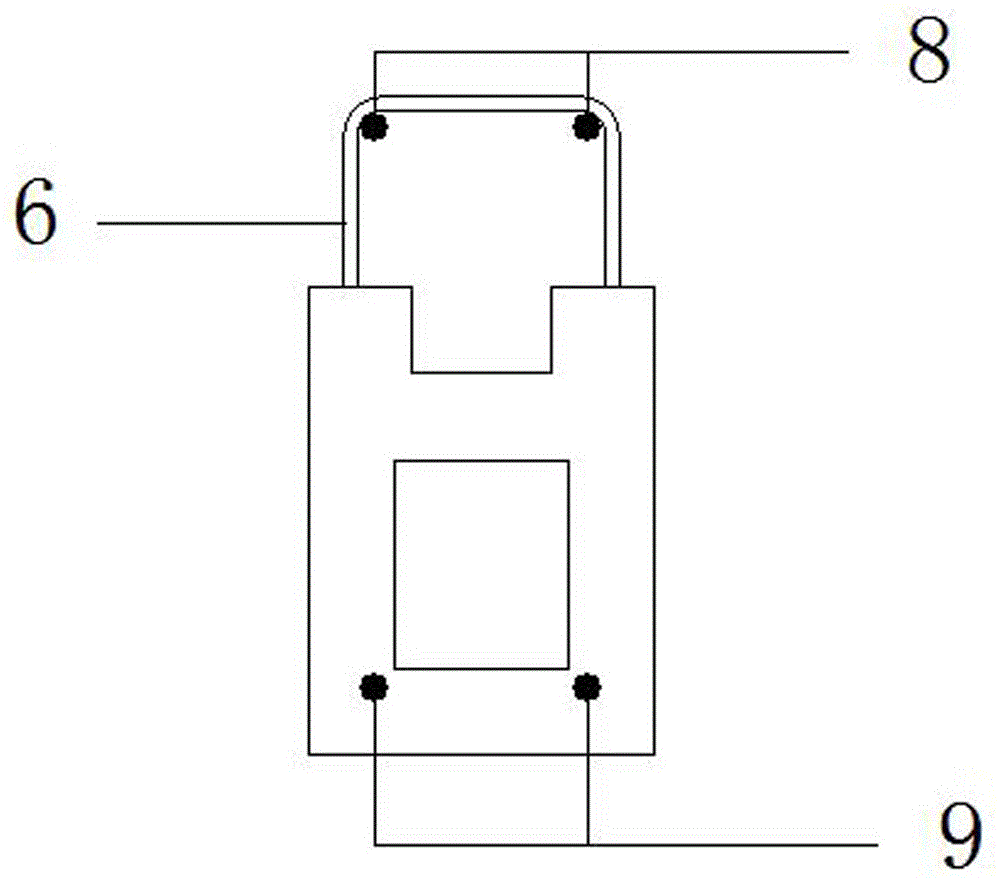

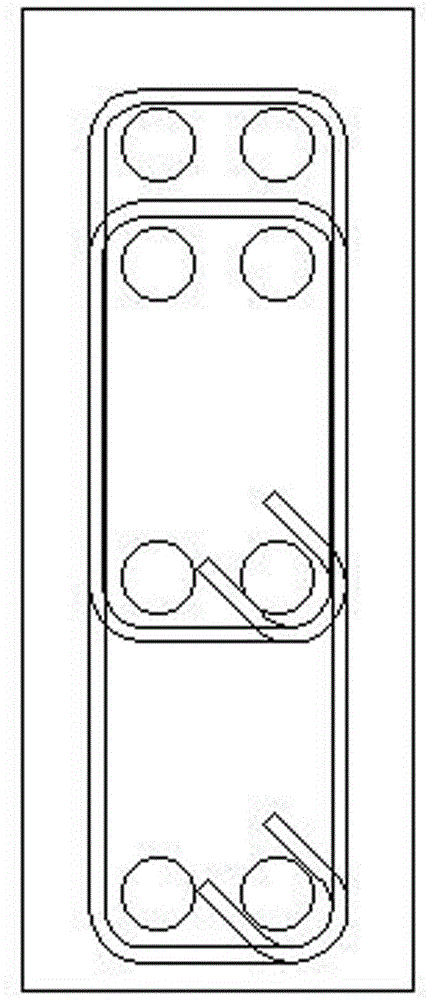

The invention discloses an assembling-type beam-column joint connection structure for a concrete special-shaped column frame, and relates to the technical field of building engineering.The assembling-type beam-column joint connection structure comprises a prefabricated special-shaped beam and a prefabricated special-shaped column, the prefabricated special-shaped beam comprises a beam-column joint and prefabricated beams, longitudinal beam rebars of each prefabricated beam are provided with reserved longitudinal beam rebars, and the beam-column joint is provided with preformed holes for longitudinal bars reserved at the upper end of the prefabricated special-shaped column to penetrate through; longitudinal bars of the special-shaped column extend to form the longitudinal bars reserved at the upper end of the prefabricated special-shaped column, semi-grouting sleeves for longitudinal bars of a prefabricated special-shaped column in a lower frame are reserved at the bottom of the prefabricated special-shaped column, the longitudinal bars at the upper end of the prefabricated special-shaped column in the lower frame penetrate through the preformed holes in the beam-column joint and are inserted into the semi-grouting sleeves at the bottom of the prefabricated special-shaped column in an upper frame, and beam-column connection is achieved by grouting slurry.According to the assembling-type beam-column joint connection structure, construction is easy, wet operation at a construction site is less, few construction processes are used, the splicing quality is high, rebar arrangement at the beam-column joint is simplified, the component connection stability is good, and good operability is achieved.

Description

technical field [0001] The invention relates to the technical field of construction engineering, in particular to a beam-column joint connection structure of an assembled concrete special-shaped column frame. Background technique [0002] In recent years, my country's construction industry has gradually transformed from traditional extensive production methods to modern industrial production methods, setting off an upsurge of housing industrialization across the country. In order to adapt to the vigorous development of housing industrialization, the prefabricated structural system has received extensive attention and research, and the standardized design of the system has become a prerequisite for realizing the industrialization of component production, assembly of construction, and socialization of management. [0003] While the prefabricated structural system has brought great changes to the construction industry, there are inevitably some defects and deficiencies. Only by...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/21E04C5/16

CPCE04B1/21E04C5/165

Inventor 付素娟董苏然贾媛媛国贤发张雄崔少华

Owner 河北省建筑科学研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com