Extruded steel bar straight thread connecting sleeve

A connecting sleeve and extruded technology, which is applied in the direction of construction, building reinforcements, building components, etc., can solve problems such as inconvenient operation, inability to guarantee project quality, and untightened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

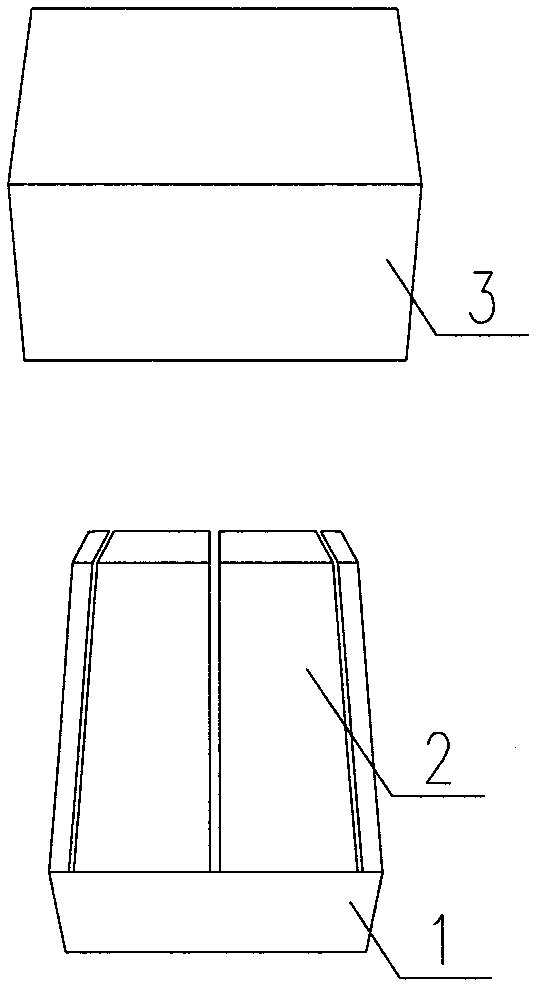

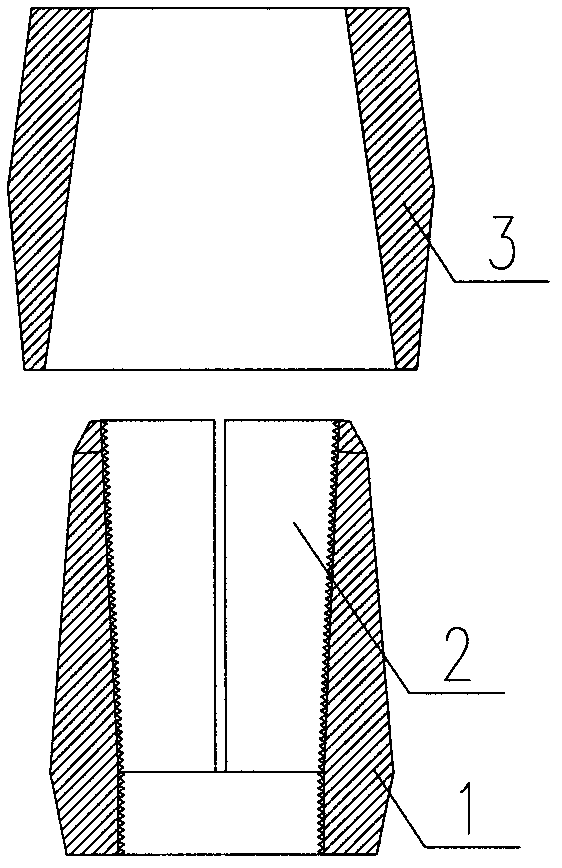

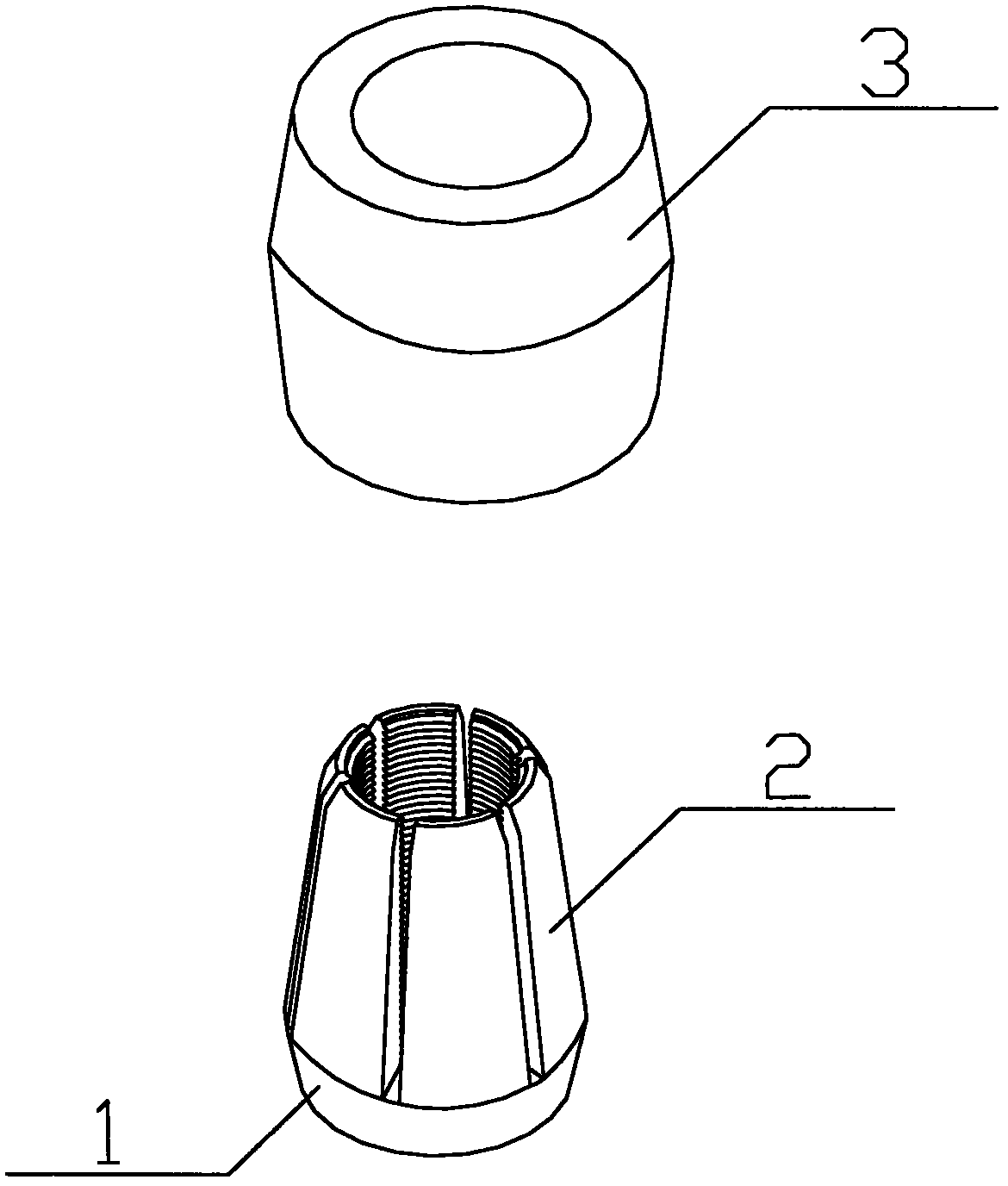

[0009] The steel bar straight thread connection sleeve of the present invention comprises two parts, an inner steel sleeve 1 and an outer steel sleeve 3 .

[0010] The inner steel sleeve 1 is hollow, and its upper and middle parts are divided into 4 to 12 steel petals 2, and the steel petals 2 are connected with the lower part of the inner steel sleeve 1 as a whole. According to the different diameters of the steel bars to be connected, the number of splits can be different, for example: for steel bars with diameters of 12mm, 14mm and 16mm, it can be divided into 4 petals; for steel bars with diameters of 18mm and 20mm, it can be divided into 6 petals; for steel bars with a diameter of 22mm , 25mm steel bars can be divided into 8 petals; for steel bars with a diameter greater than 25mm, they can be divided into 12 petals. It should be noted that the above splitting method is only an example, and different splitting numbers can also be selected according to actual construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com