Pipeline connecting device

A technology for connecting devices and pipes, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, engine sealing, etc., can solve the problems of complicated assembly work, increased production cost, wrong assembly, etc., and achieves low production process requirements and reduced The amount of use, the effect of ensuring the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

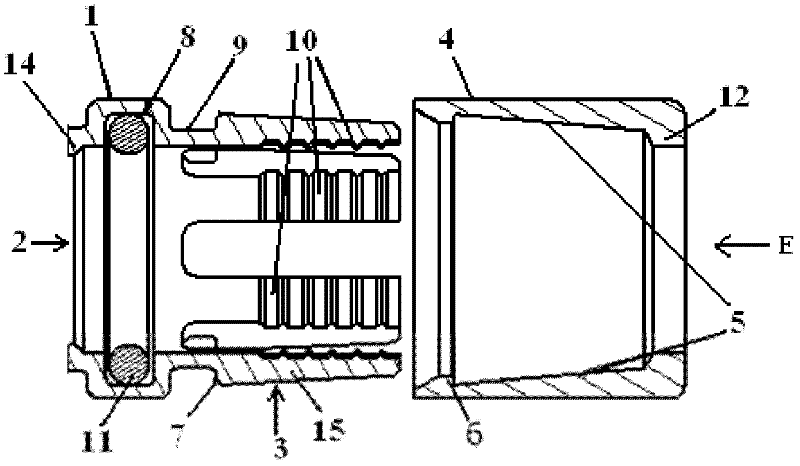

[0052] Such as figure 1 The shown pipeline connection device includes: a joint body 1 having a channel 2; and also includes:

[0053] Several elastic pieces 3, the elastic pieces 3 are distributed circumferentially at the port of the channel 2 of the joint body 1, and one end is fixedly connected with the joint body 1, and are used to insert the pipe inserted into the channel 2 Clamping; in this embodiment, the elastic piece 3 is preferably a tapered piece integrally formed on the joint body 1, the thickness of the tapered piece in the radial direction increases gradually along the pipeline entering direction, and the tapered piece The shaped piece preferably has a flat peripheral outer surface; and the inner wall of the tapered shaped piece in contact with the pipe is formed with a locking tooth 10 . The conical piece preferably has: an elastic connecting section, located at one end of the conical piece, connected to the joint body 1; and a clamping section, located on the c...

Embodiment 2

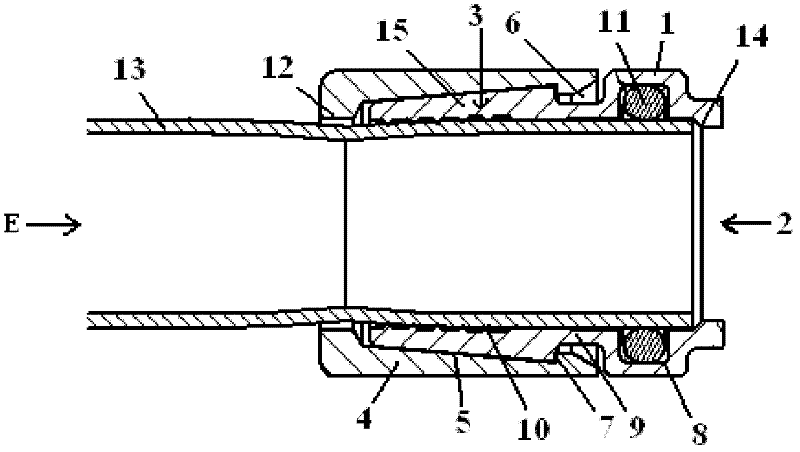

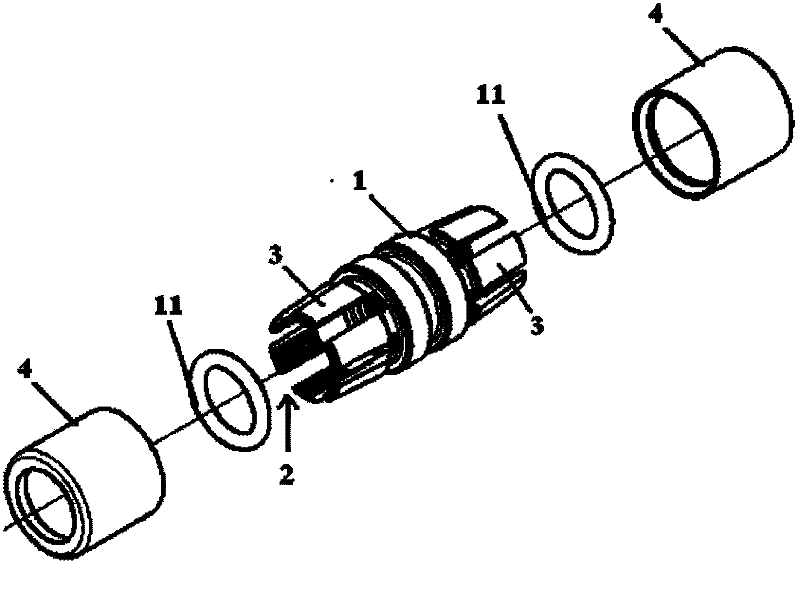

[0065] Such as Figure 4 The pipeline connection device shown includes: a joint body 1 having a channel 2; and also includes: several elastic pieces 3 distributed circumferentially on the channel 2 of the joint body 1 port, and one end is fixedly connected to the joint body 1 for clamping the pipe inserted into the channel 2; in this embodiment, the elastic piece 3 is preferably integrally formed on the joint body 1 The radial thickness of the tapered sheet gradually increases along the pipe entering direction; and the inner wall of the tapered sheet in contact with the pipe is formed with locking teeth 10 . The conical piece preferably has: an elastic connecting section 9, located at one end of the conical piece, connected to the joint body 1; The thickness of the other end of the tapered piece 3 is greater than that of the elastic connecting section 9 .

[0066] It also includes a locking nut 4, the locking nut 4 has a first end close to the joint body 1 and a second end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com